Loading ...

Loading ...

Loading ...

32

17

10

11

Qty - 5

14

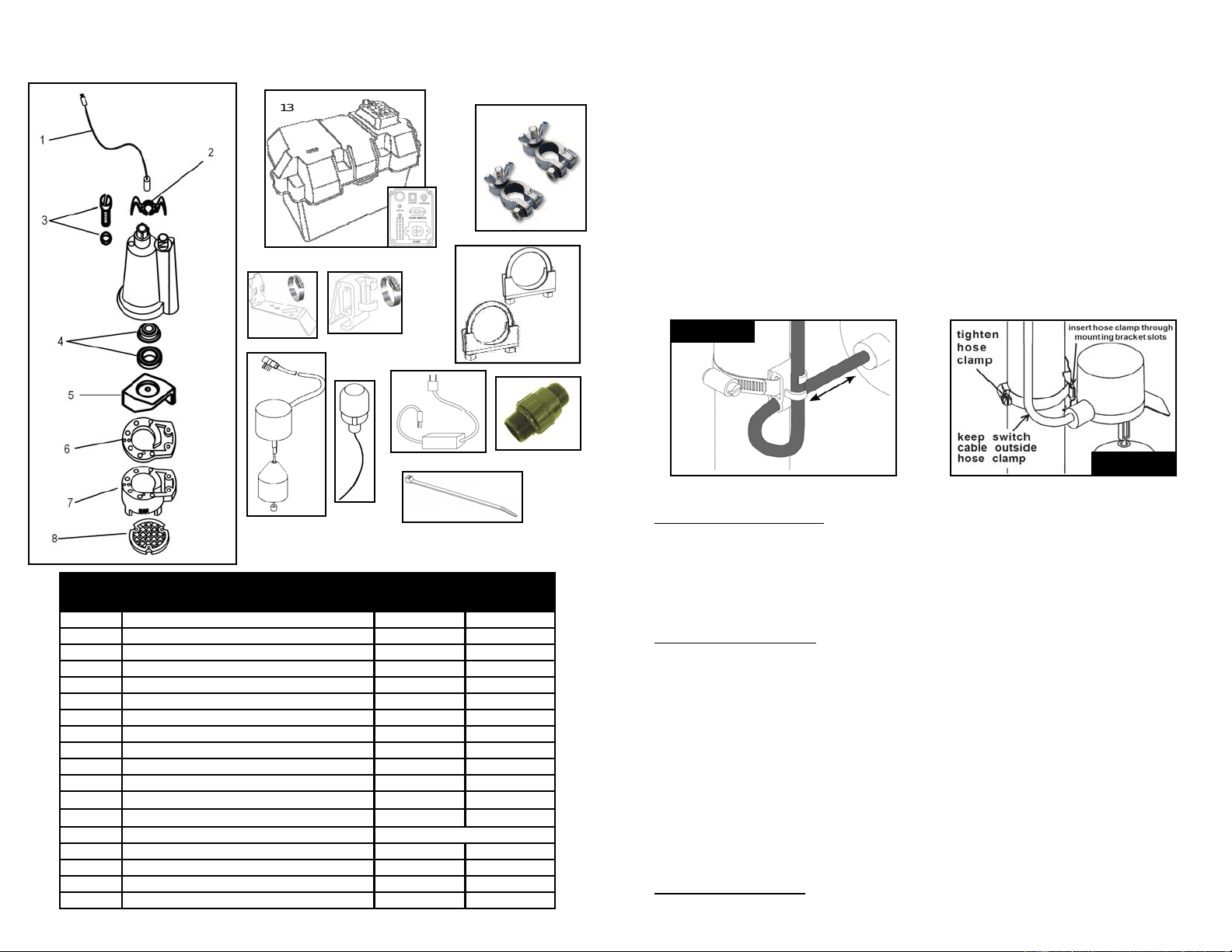

Ref Descripción

PIEZAS PARA EL MODELO

92370

92372

1 Cable de alimentación 99158 99158

2 Asa 99051 99051

3 Tapón de llenado de aceite con junta tórica 99056 99056

4 Sello de eje 99057 99057

5 Impulsor 99065 99065

6 Junta 99088 99088

7 Voluta y base 99098 99098

8

Rejilla de entrada

99059

99059

9 Interruptor de flotador 92050 92055

10

Abrazadera para interruptor de flotador con amarre

99180

n/a

11 Soporte para interruptor de flotador vertical n/a 99185

12 Conjunto de perno en U y abrazadera de silla 99462 99462

13 Caja para batería (unidad completa) 99464 99464

14 Ataduras para cable

15

Tablero de control

99465

99465

16 Cable de alimentación de CA 99467 99467

17 Terminales de batería (+ y - ) 99460 99460

18 Válvula de paso 99505 99505

Compre localmente

LISTA DE PIEZAS

Para ordenar piezas de repuesto, llame al 1-800-495-9278

15

13

18

16

9

9

12

5

9. Thread the check valve (C) onto the discharge of the back-up pump

10. Plumb the back-up pump to the primary pump piping using a 1-1/2” Female Adapter (D),

45° Street Elbow (E) and a Wye fitting (F). It is highly recommended to do a “dry fit”

before permanently gluing the pipe and fittings together. Place the assembly in the basin

to make sure that it fits and that the primary float switch operates freely before

permanently gluing the pipe and fittings together.

11. Remove the assembly from the basin and glue all fittings.

12. Next, secure the float switch to the discharge pipe using the provided clamp. See figure 2

below for proper installation. DO NOT fully tighten the clamp at this time. Leave it a bit

loose so you can adjust the position of the float in the next steps.

13. After the float switch has been attached to the discharge pipe, place the entire assembly

in the basin. Make sure the primary pump float switch will operate freely and not contact

the sides of the basin. Connect the pump assembly to the discharge pipe. Use either a

flexible coupling with clamps or a solvent weld PVC or ABS coupling.

Tethered Switch Installation

Adjust the tether length of the float switch so the back up pump will turn on when the water

level rises above the start level of the primary pump. Make sure the “on” level does not exceed

the top of the basin. It is recommended to keep at least a 2” clearance from the top of the

basin. Position the float so that it will operate freely and not contact the sides of the basin or

the primary pump. Once positioned properly, completely tighten the float switch clamp.

Vertical Switch Installation

Position the Vertical Float Switch on the discharge pipe so it will turn on when the water level

rises above the start level of the primary pump. Make sure the “on” level does not exceed the

top of the basin. It is recommended to keep at least a 2” clearance from the top of the basin.

You can adjust the “off” level of the vertical float by moving the grommet up or down on the

vertical float rod. Once positioned properly, completely tighten the float switch clamp.

NOTE: There are many different options for assembling this unit. The instructions above

represent one of the most common installations. Your installation may vary. If you have a very

shallow basin, mounting the back-up pump above the primary pump may not be feasible. You

may also position the pump on bottom of the basin. Make sure the back up pump is positioned

so that it won’t interfere with the primary pump operation. If you have any questions about your

particular installation, please feel free to contact us at 1-800-495-9278 or at

www.superiorpumpco.com

TETHERED SWITCH INSTALLATION VERTICAL SWITCH INSTALLATION

Adjust tether

length to desired

activation level

FIGURE 2

FIGURE 2

Loading ...

Loading ...

Loading ...