Loading ...

Loading ...

Loading ...

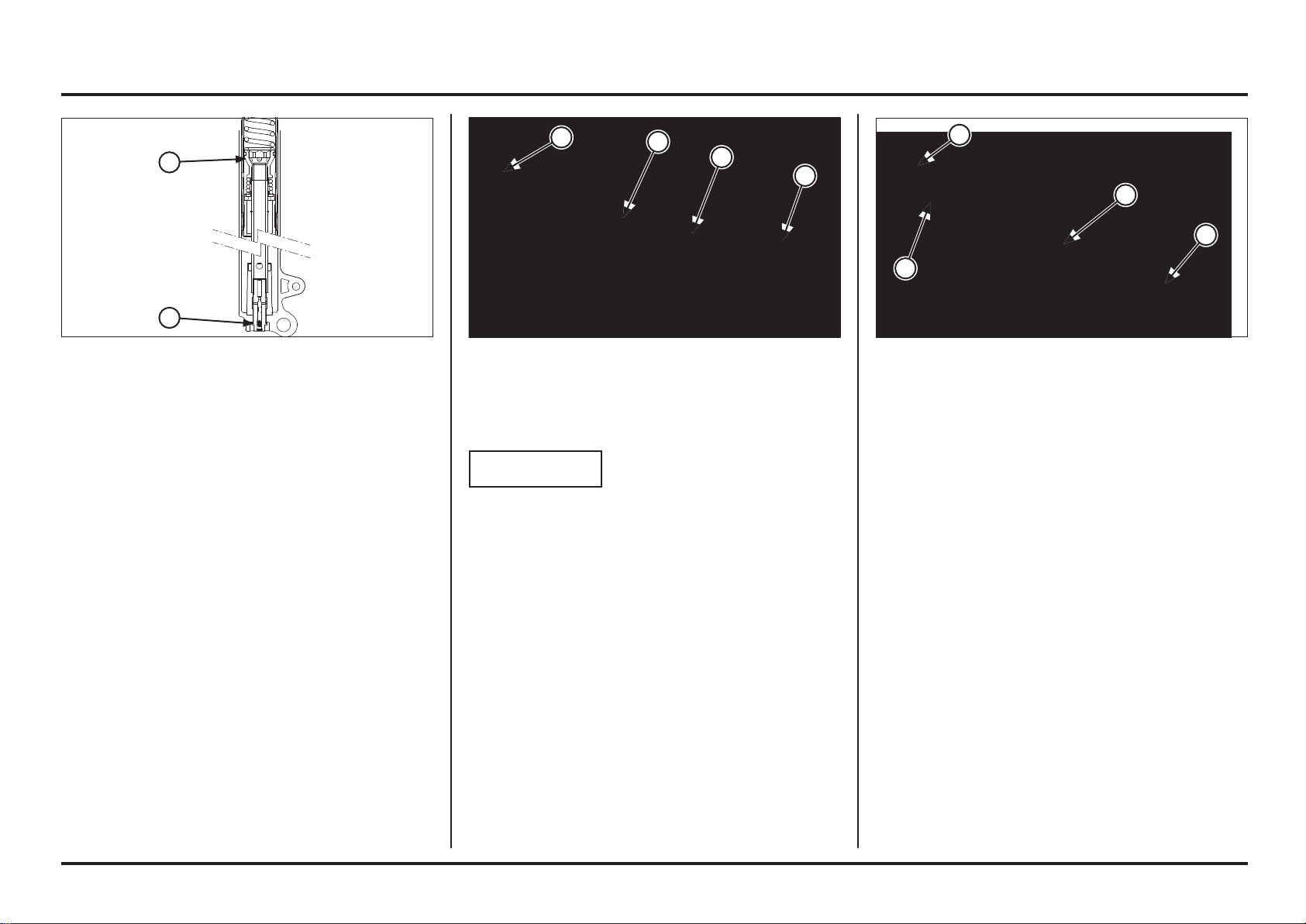

(1) CILINDER ASSY

(2) PISTON RING

(3) REBOUND SPRING

(4) TAPERED BUSHING

Left Fork Inspection

Check the following items (page 2-1):

– Inside fork slider for damage or deformation

– Fork tube runout

– Fork spring free length

– Fork tube for score marks, scratches and excessive

wear

– Bushing/back-up ring (page 5-5)

– Fork piston ring for wear or damage

– Tapared bushing for damage

– Rebound spring for fatigue or other damage

(1) FORK TUBE

(2) CILINDER ASSY

(3) TAPERED BUSHING

(4) FORK SLIDER

Remove the tapered bushing from the fork piston.

NOTE

Be careful not to damage the tapared bushing.

Remove the cilinder assy from the fork tube.

Remove the following items using the same procedure as

the right fork disassembly (page 5-3):

– Oil seal

– Back-up ring

– Guide bushing

– Fork tube bushing

Hold the axle holder in a vise protected with a piece of

wood or soft jaws to avoid damage.

Do not overtighten.

Hold the cilinder assy using the special tool and loosen

the center bolt as shown.

Tools:

Fork damper holder 07930–KA50100

Remove the center bolt and sealing washer.

Remove the following items using the same procedure as

the right fork disassembly (page 5-3):

– Dust seal

– Stop ring

– Fork tube, unlocking guide bushing on the fork leg.

(1) CILINDER ASSY

(2) CENTER BOLT

5-9

5-9

Frame servicing

2

1

3

2

1

4

3

2

1

4

Loading ...

Loading ...

Loading ...