Documents: Go to download!

- Owner's manual - (English)

- Features and Controls

- Operation

- Maintenance and Adjustments

- Storage

- Troubleshooting

- Specifications

Table of contents

Features and Controls

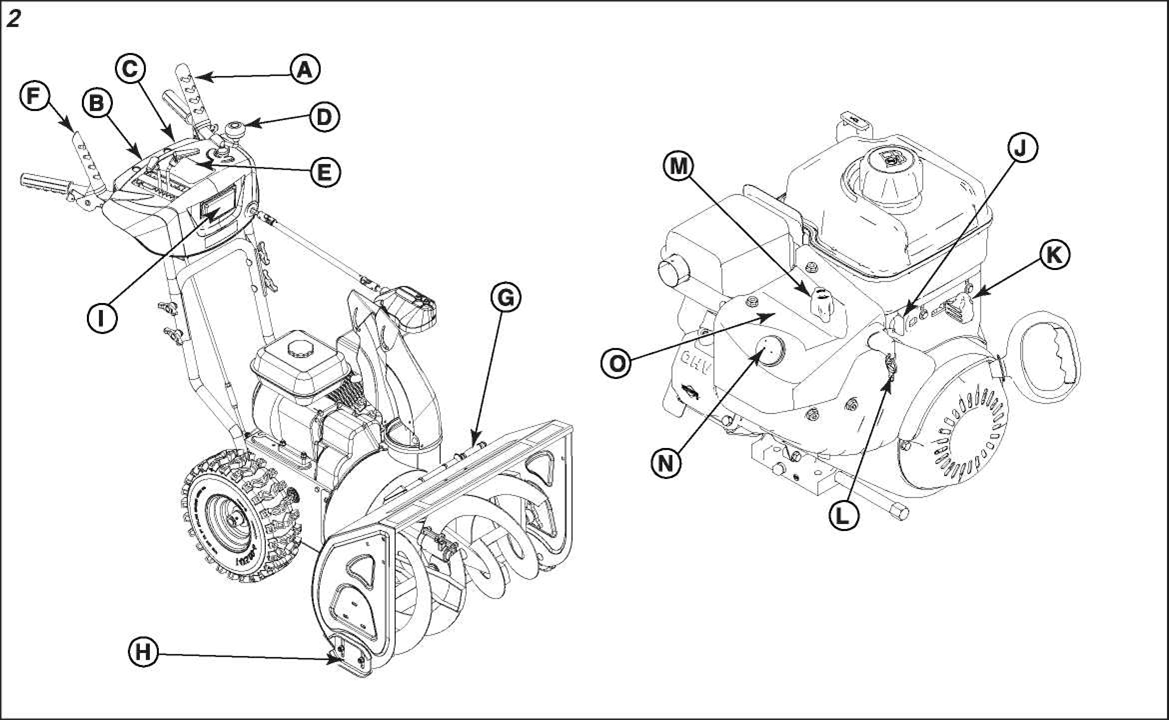

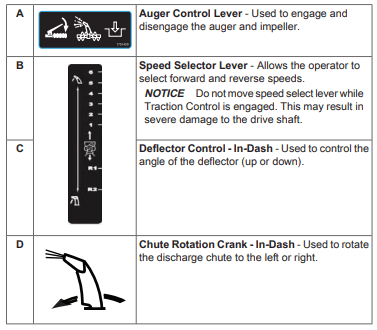

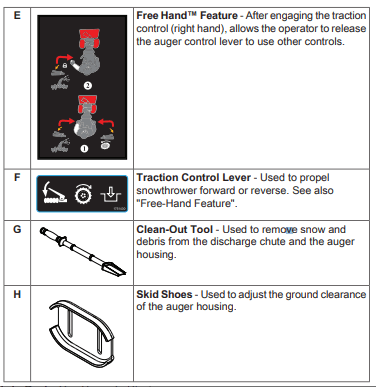

Match the call out letters in Figure 2 to the features and controls listed in the accompanying table

Control Symbols and Meanings

Operation

WARNING: This snowthrower is only as safe as the operator. If it is misused, or not properly maintained, it can be dangerous. Remember you are responsible for your safety and those around you.

- When leaving the operating position always disengage the auger, turn off the engine, and remove the key. Never leave a running machine unattended.

- Never operate the snowthrower without proper guards, and other safety protective devices in place and working.

- Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for hidden hazards or traffic.

- Never operate the snowthrower without good visibility or light. Always be sure of your footing, and keep a firm hold on the handles. Walk; never run.

- Exercise caution to avoid slipping or falling, especially when operating the snowthrower in reverse.

- Exercise extreme caution when operating on slopes.

- After striking a foreign object, stop the engine (motor), remove the wire from the spark plug, disconnect the cord on electric motors, thoroughly inspect the snowthrower for any damage, and repair the damage before restarting and operating the snowthrower.

- Do not operate the equipment without wearing adequate winter garments. Avoid loose fitting clothing that can get caught in moving parts. Wear footwear that will improve footing on slippery surfaces.

- Never touch a hot muffler or engine. Allow muffler/engine cylinder to cool before touching.

Operating Area

1. Familiarize yourself with the area in which you plan to operate the snowthrower. Mark off all boundaries of walkways and driveways.

2. Ensure the area to be cleared is free of debris or objects that could be picked up by the auger and thrown from the chute.

WARNING  : This machine is capable of throwing objects that could injure bystanders or cause damage to buildings.

: This machine is capable of throwing objects that could injure bystanders or cause damage to buildings.

3. Before starting the engine, move the snowthrower outdoors and away from windows and doors.

WARNING  : Engines give off carbon monoxide, an ordorless, colorless, poison gas. Breathing carbon monoxide can cause nausea, fainting, or death.

: Engines give off carbon monoxide, an ordorless, colorless, poison gas. Breathing carbon monoxide can cause nausea, fainting, or death.

- Start and run engine outdoors

- Do not run the engine in an enclosed area, even if doors or windows are open

4. Ensure the operating area is clear of bystanders, especially children.

WARNING  : This snowthrower is capable of amputating hands and feet, and throwing objects. Read and observe all the safety instructions in this manual. Failure to do so could result in death or serious injury.

: This snowthrower is capable of amputating hands and feet, and throwing objects. Read and observe all the safety instructions in this manual. Failure to do so could result in death or serious injury.

- Keep children out of the area during operation

- Children are often attracted to the equipment. Be mindful of all persons present

- Be alert and turn the unit off if bystanders enter the area.

- Use extra care when approaching blind corners, shrubs, tress, or other objects that may obscure vision.

Starting the Engine

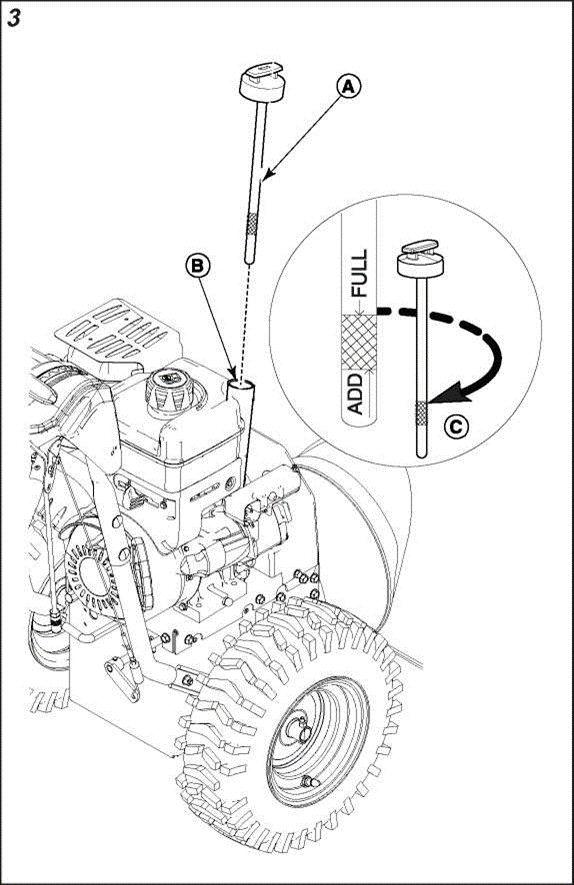

Checking Oil

NOTICE

The engine was shipped from the factory without oil. Before you start the engine, ensure that you add oil according to the instructions in this manual. If you start the engine without oil, it will be damaged beyond repair and will not be covered under the warranty.

Use Briggs & Stratton Synthetic 5W-30 Warranty Certified oil for best performance. Other high-quality detergent oils are acceptable if classified for service SG, SH, SJ or higher. Do not use any additives.

- Place the unit on a level surface.

- Clean the oil fill area of any moisture or debris.

- Remove the oil dipstick (A, Figure 3) and wipe it with a clean cloth

- Insert and tighten the dipstick, then remove it again to check the oil level. It should be at the top of the full indicator (C)

- To add oil, pour slowly into the engine oil fill (B). Do not overfill.

- Wait one minute before checking the oil level

- When the oil level is at the top of the full indicator (C), install and tighten the dipstick

Adding Fuel

Fuel must meet these requirements:

- Clean, fresh, unleaded gasoline

- A minimum of 87 octane / 87 AKI (90 RON)

- Up to 10% ethanol is acceptable

NOTICE

Do not use unapproved gasolines, such as E15 and E85. Do not mix oil in gasoline or modify the engine to run on alternate fuels. Use of unapproved fuels will cause engine damage that will not be covered under warranty.

At altitudes over 5,000 feet (1524 meters), a minimum 85 octane / 85 AKI (89 RON) gasoline is acceptable. To remain emissions compliant, high altitude adjustment is required. Operation without this adjustment will cause decreased performance, increased fuel consumption, and increased emissions. See an authorized service dealer for high altitude adjustment information. Operation altitudes below 2,500 feet (762 meters) with the high altitude adjustment is not recommended.

WARNING  :

:

Fuel and its vapors are extremely flammable and explosive. Always handle fuel with extreme care.

Failure to observe these safety instructions can cause a fire or explosion which could result in serve burns or death

- Do not add fuel while engine is running. Let the engine cool at least 2 minutes before adding fuel.

- Fill the fuel tank outdoors only, using an approved fuel container with the unit directly on the ground.

- Keep fuel away from sparks, open flames, pilot lights, heat, and other ignition sources.

- Allow any spilled fuel to evaporate before starting the engine.

- If fuel is spilled on clothing change clothing immediately

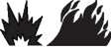

- Slowly remove the fuel cap (A, Figure 4) and fill the tank (B) with fuel. Do not fill higher than the bottom of the fuel tank neck (C).

- Reinstall the fuel cap. Allow any spilled fuel to evaporate before starting the engine.

Starting Engine

WARNING  :

:

Fuel and its vapors are extremely flammable and explosive. Always handle fuel with extreme care.

Failure to observe these safety instructions can cause a fire or explosion which could result in serve burns or death.

- Ensure that spark plug, muffler, fuel cap, and air cleaner (if equipped) are in place and secured.

- Do not crank the engine with the spark plug removed.

- Do not use pressurized starting fluids because their vapors are flammable.

- Do not over-prime the engine. Follow the engine starting instructions in this manual.

- If the engine floods, set choke (if equipped) to OPEN/RUN position, move throttle (if equipped) to FAST position and crank until engine starts.

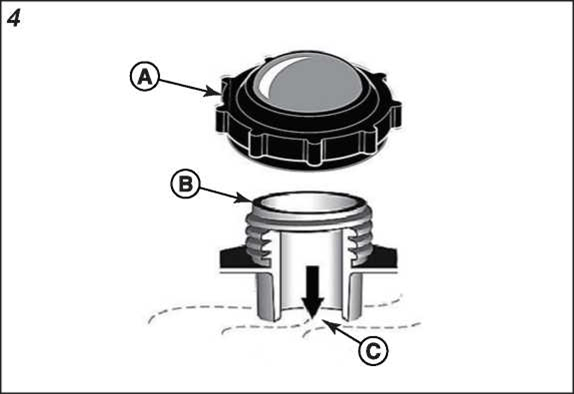

1. Ensure the auger control (A, Figure 5) and traction control (K) are disengaged.

2. Turn the fuel shut-off valve (C) (if equipped) to the Open position.

3. Move the throttle control (D) (if equipped) to the Fast position.

4. Insert the ignition key (E) and turn it to the ON position or insert the push/pull key.

5. Turn the choke control (F) to the Closed position.

Note: Choke is usually not needed when starting a warm engine.

6. Press the primer (G) two times.

Note: Primer is usually not needed when starting a warm engine.

7. For rewind start: Firmly hold the starter cord handle (H). Pull the handle slowly until resistance is felt, then pull rapidly.

WARNING  : Rapid retraction of the starter cord (kickback) will pull your hand and arm toward the engine faster than you can let go. Broken bones, fractures, bruises, or sprains could result.

: Rapid retraction of the starter cord (kickback) will pull your hand and arm toward the engine faster than you can let go. Broken bones, fractures, bruises, or sprains could result.

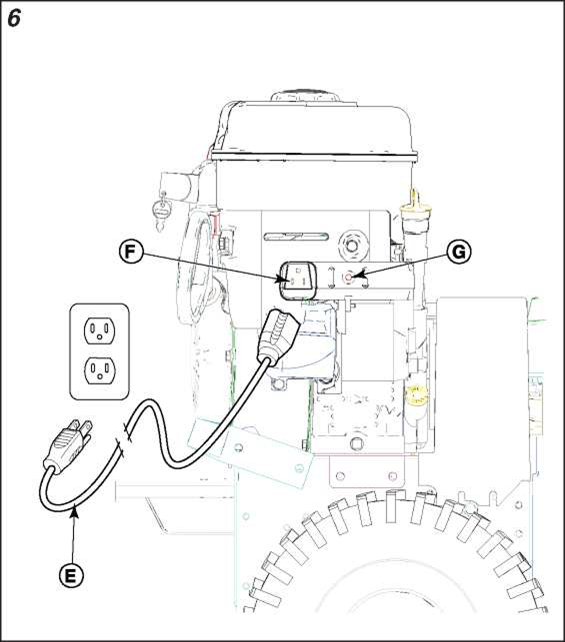

8. For electric start: Connect the extension cord (E, Figure ^ 6) to the starter box (F) on the engine, and then to the wall receptacle. Press the starter box pushbutton (G). After the engine starts, disconnect the extension cord from the wall ^ receptacle and then from the starter box.

WARNING  : Damaged or ungrounded power cords could cause electric shock. Electric shock could cause severe burns or death.

: Damaged or ungrounded power cords could cause electric shock. Electric shock could cause severe burns or death.

- Use only a three-conductor power cord properly grounded to the power source.

- If the extension cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly qualified person.

NOTICE To extend the life of the starter, use short starting cycles (five seconds maximum). Wait one minute between starting attempts.

If the engine does not start after repeated attempts, contact an authorized service dealer or go to our website.

9. Allow the engine to warm up for several minutes. Gradually move the choke control (F, Figure 5) to the Open position

Stopping the Engine

- Turn the ignition key (E, Figure 5) to the Off position and remove it or remove the push/pull key (if equipped).

- Keep the key in a safe place out of the reach of children. The engine cannot be started without the key.

Adjusting the Discharge Chute and Deflector

WARNING

Ice, gravel, or other unintended objects can be picked up by the auger and thrown from the chute with force

Objects thrown from the chute could cause death, serious injury, or property damage

- Always be aware of the direction the snow is being thrown.

- Rotate the chute rotation crank (I, Figure 5) to set the direction of the discharge chute.

- Use the deflector control lever (J) to move the deflector up or down. Raise the deflector to throw snow further.

- Use the speed select lever (B) to select the forward or reverse drive speed. Use lower speeds when clearing wet, heavy snow. Use higher speeds for light snow or transporting.

Note: Always release the traction control lever before changing speeds.

Engaging the Auger and Impeller

The auger and impeller work together to break up the snow as the snowthrower moves forward and throws it out the discharge chute.

DANGER  : The snowthrower contains a rotating auger and impeller to throw snow. Fingers or feet can quickly become caught in the auger or impeller resulting in traumatic amputation or severe laceration.

: The snowthrower contains a rotating auger and impeller to throw snow. Fingers or feet can quickly become caught in the auger or impeller resulting in traumatic amputation or severe laceration.

- Fully press the auger control lever (A, Figure 5) on the left handle to engage the auger and impeller.

- Release the lever to stop the auger. The auger must stop within 5 seconds after the auger control is released. If it does not:

- Adjust the control cable. See Adjusting the Auger and Traction Cable.

- If the auger still does not stop within 5 seconds, see an authorized dealer.

Engaging the Drive Wheels

NOTICE: Do not move the speed select control while the traction control is engaged. This may result in damage to the drive system.

1. To drive forward, shift the speed select control (B, Figure 5) into one of the forward positions. Select a lower number for heavy snow, a middle number for light snow, and a higher number for moving without snow removal.

2. Press and hold down the traction control (K) on the right handle.

3. To stop, release the traction control. Unit must stop immediately. If it does not;

- Adjust the traction control cable. See Adjusting the Auger and Traction Cable.

- If the unit still does not stop, see an authorized dealer.

4. To drive backward, shift the speed select control into one of the reverse positions.

5. Press and hold down the traction control on the right handle.

6. To stop, release the traction control. Unit must stop immediately. If it does not;

- Adjust the traction control cable. See Adjusting the Auger and Traction Cable.

- If the unit still does not stop, see an authorized dealer.

NOTICE: Do not overload the machine capacity by attempting to clear snow at too fast of a rate.

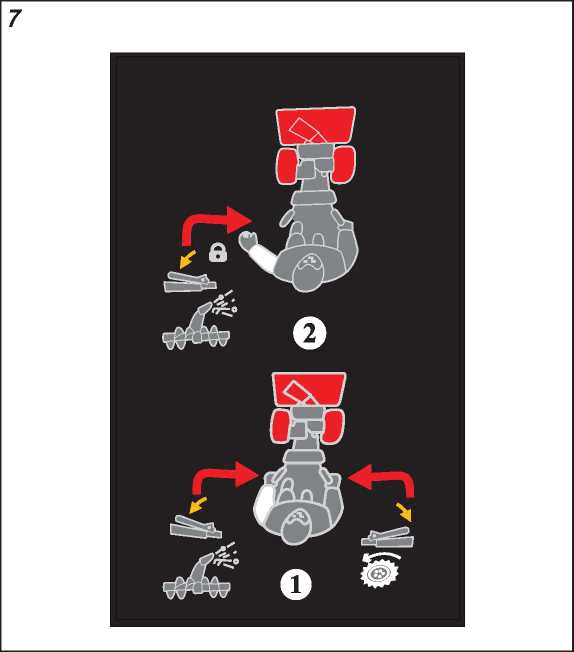

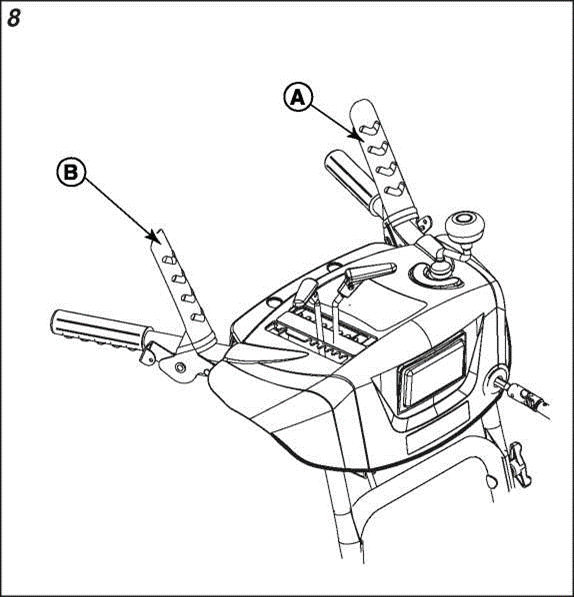

Using Free Hand™ Feature

Some models are equipped with the Free Hand™ feature, which allows the operator to release the auger control to reach other controls without stopping the unit. If your model is equipped with Free Hand, it will have the decal shown in Figure 7 affixed to the dash panel.

- Press down and hold the auger control (A, Figure 8).

- Press down and hold the traction control (B).

- Release the auger control so the left hand is free to reach other controls.

- If the auger stops, see an authorized dealer.

Note: Free Hand cannot be actuated by releasing the traction control.

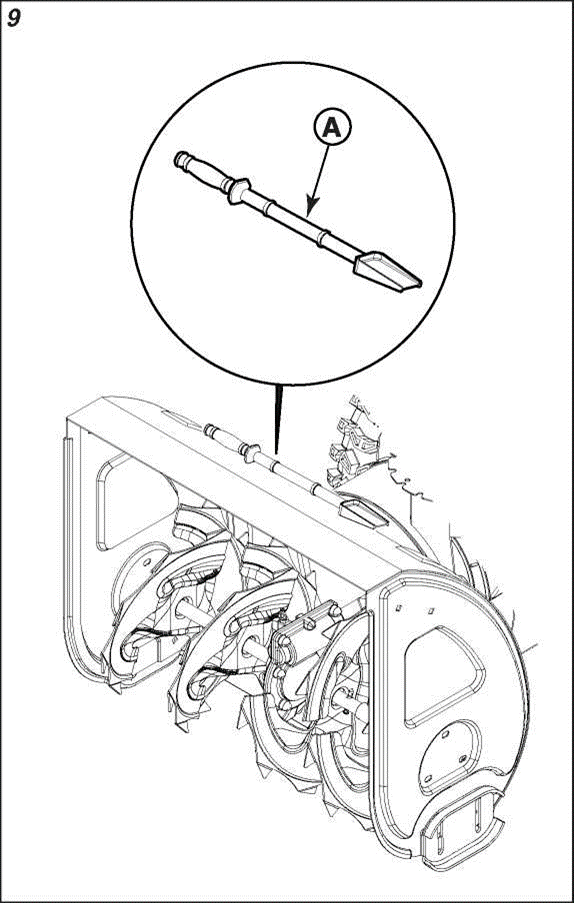

Clearing a Clogged Discharge Chute

DANGER ® : The discharge chute contains a rotating impeller to throw snow. Fingers can quickly become caught in the impeller resulting in traumatic amputation or severe laceration. Never clear a clogged discharge chute with your hands. Always use a clean-out tool.

To safely clear a clogged discharge chute, follow these instructions:

- Stop the engine and remove the key.

- Ensure that the impeller has stopped rotating.

- Use a clean-out tool (A, Figure 9) to remove snow from the discharge chute. Never clear a clogged discharge chute with your hands!

Using the Headlight

Some models are equipped with a headlight (L, Figure 5) to help illuminate the area in front of the snowthrower. The headlight is on whenever the engine is running. There is no switch

Using the Wheel Release - Lock Pins

One or both wheels can be temporarily disengaged from the drive axles for ease of handling when transporting the unit.

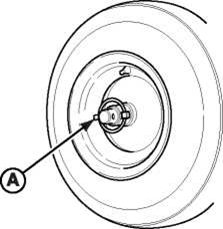

1. Open the pull ring (A, Figure 10) over the wheel hub.

2. Insert the retaining pin through the outer hole in the axle and close the pull ring over the axle.

3. To engage the wheel and axle, align the wheel hub and the inner axle hole, then install the retaining pin fully and close the pull ring over the wheel hub.

Maintenance and Adjustments

We recommend contacting an authorized service dealer for all maintenance, adjustments, and servicing of the unit. Some routine maintenance tasks can be performed by the owner. Refer to the maintenance schedule and procedures that follow.

CAUTION: All the components used to build this product must remain in place for proper operation. Replacement parts must be of the same design and installed in the same position as the orginial parts. Other parts may not perform as well, may damage the unit, and may result in injury.

WARNING  : This snowthrower must be properly maintained to ensure safe operation and performance. Failure to observe the safety instructions in this manual could result in death or serious injury

: This snowthrower must be properly maintained to ensure safe operation and performance. Failure to observe the safety instructions in this manual could result in death or serious injury

- Before performing any maintenance or repairs on the snowthrower, shut OFF the engine and remove the ignition key or the push/pull key.

Maintenance Schedule

First 5 Hours

Change oil

Before Each Use

- Check engine oil level

- Check auger and impeller stop time

After Each Use

Remove accumulated snow and slush to prevent freezing of the controls, wheels, discharge chute, and auger

Every 25 Hours or Annually

- Change the engine oil

- Check tire pressure

- Check auger and traction cable adjustment

- Lubricate control lever linkages

- Lubricate the discharge chute and deflector

- Lubricate the auger assembly

- Lubricate the hex shaft and gear

- Lubricate the drive wheel axles

- Check muffler and spark arrester (if equipped)

- Clean, gap, or replace sparkplug (dealer service)

- Check valve clearance (dealer service)

Emissions Control

Maintenance, replacement, or repair of the emissions control devices and systems may be performed by any non-road engine repair establishment or individual. However, to obtain “no charge” emissions control service, the work must be performed by a factory authorized dealer.

Changing the Engine Oil

Used oil must be disposed of properly. Do not discard with household waste. Check with your local authorities, service center, or dealer for safe disposal or recycling facilities.

Use Briggs & Stratton Synthetic 5W-30 Warranty Certified oil for best performance. Other high-quality detergent oils are acceptable if classified for service SG, SH, SJ or higher. Do not use any additives.

1. With the engine stopped but still warm, turn the ignition key to the OFF position and remove it or pull out the push/pull key (if equipped).

WARNING  : Fuel and its vapors are extremely flammable, which could cause burns or fire resulting in death or serious injury.

: Fuel and its vapors are extremely flammable, which could cause burns or fire resulting in death or serious injury.

- When performing maintenance that requires the unit to be tipped, the fuel tank must be empty or fuel can leak out and result in a fire or explosion.

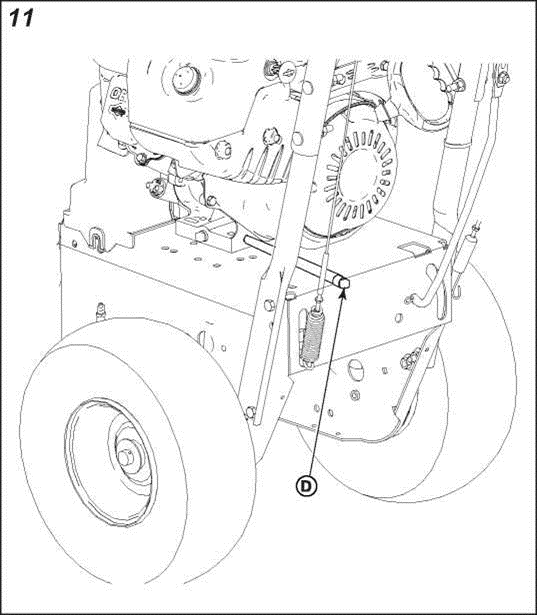

2. Remove the oil drain plug (D, Figure 11) and tilt the snowthrower slightly to drain the oil into an appropriate container.

3. After the oil has drained, install and tighten the oil drain plug (D).

4. Place the unit on a level surface.

5. Clean the oil fill area of any moisture or debris.

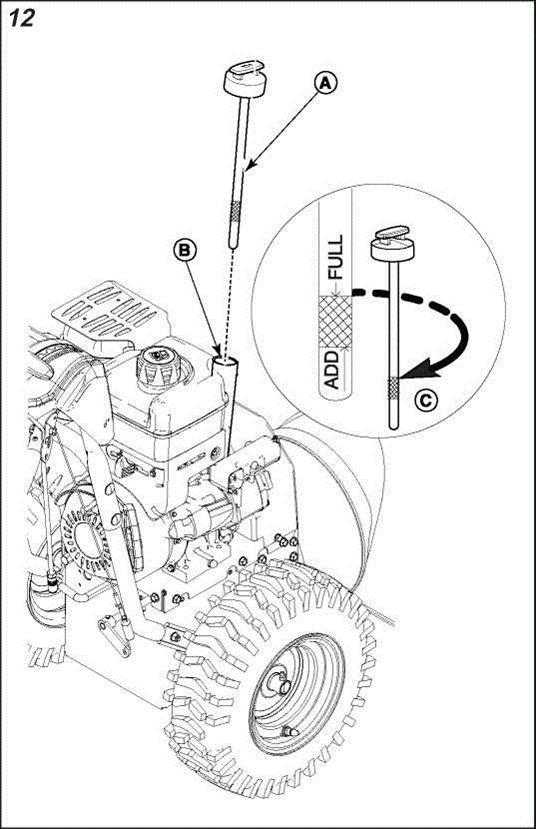

6. Remove the dipstick (A, Figure 12) and wipe it with a clean cloth. Set it aside.

7. To add oil, pour slowly into the engine oil fill tube (B). See Specifications for the oil capacity. Do not overfill.

8. Wait one minute before checking the oil level.

9. Insert and tighten the dipstick, then remove it again to check the oil level. It should be at the top of the full indicator (C).

10. When the oil level is at the top of the full indicator, install and tighten the dipstick.

Adjusting the Skid Shoe Height

DANGER

This snowthrower contains a rotating auger to collect snow. Fingers can quickly become caught and traumatic amputation or severe laceration will result.

Turn the engine OFF, wait for all moving parts to stop, and remove the ignition key or push/pull key before performing any maintenance or repairs.

WARNING

lf struck by the auger or impeller, objects such as gravel, rocks, or other debris may be thrown with sufficient force to cause personal injury, property damage, or damage to the snowthrower.

Skids shoes are secured to either side of the auger housing. They can be adjusted to increase or decrease the distance between the scraper bar and the surface to be cleared.

Set the skid shoes at the proper height to maintain ground clearance for the type of surface being cleared.

1. Shut the engine off and remove the key.

2. Determine the scraper bar clearance needed for the surface to be cleared

- When removing snow from a hard surface area such as a paved driveway or walk, adjust the skids shoes up to lower the scraper bar closer to the surface.

- When removing snow from gravel-covered or uneven surfaces, adjust the skids shoes down to raise the scraper bar further from the surface. This will help prevent rocks and other debris from being picked up and thrown by the auger and impeller.

3. Place the unit on a level surface

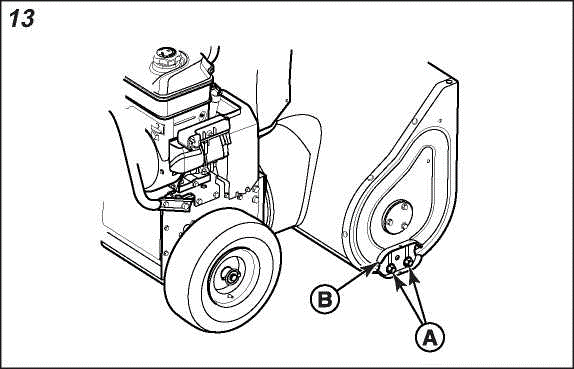

4. Loosen the skid shoe mounting nuts (A, Figure 13) on the skid shoe (B).

5. Under each end of the scraper bar, place a wooden block of the same thickness as the desired clearance height.

6. Allow each skid shoe to firmly touch the surface. Then tighten the mounting nuts.

NOTICE: To prevent contact with the auger, ensure the mounting nuts are to the outside of the auger housing.

Lubricating the Control Lever Linkage

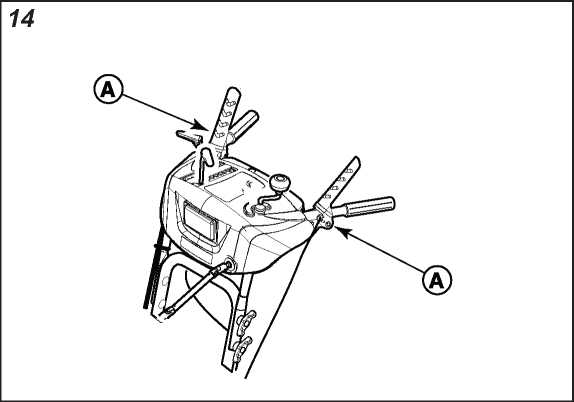

Lubricate the control lever linkage (A) at the locations shown in Figure 14. Use fresh, clean engine oil.

Lubricating the Discharge Chute, Deflector, and Wheel Axle

- Shut off the engine and remove the key.

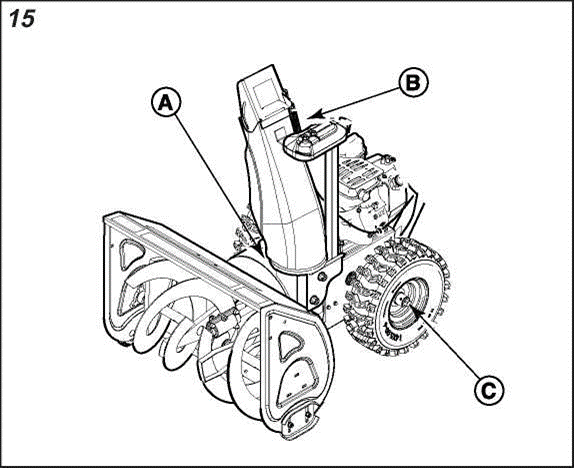

- At the locations shown in Figure 15:

- Lubricate the discharge chute (A) with lithium grease.

- Lubricate the deflector (B) with fresh, clean engine oil.

- Lubricate both wheel axles (C) with lithium grease.

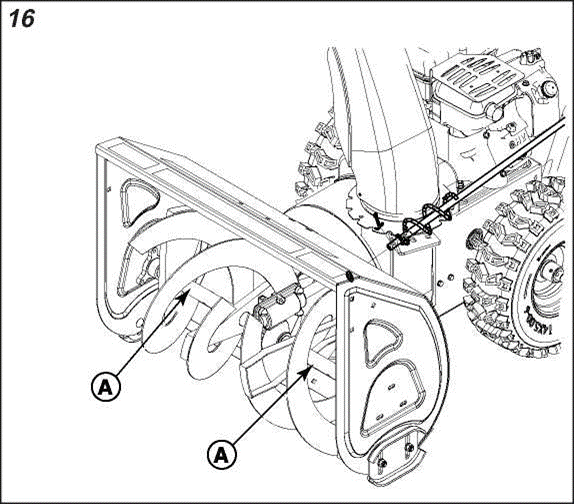

Lubricating the Auger Assembly

- Shut off the engine and remove the key.

- Lubricate the auger shaft assembly (A, Figure 16) with grease at the grease fittings, (if equipped).

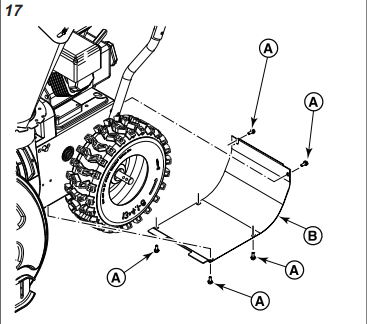

Lubricating the Hex Shaft and Gear

NOTICE: Do not allow grease or oil to contact the rubber friction wheel or the disc drive plate. If grease or oil comes into contact with the friction wheel, replace it. Do not attempt to clean it. If grease or oil comes into contact with disc drive plate, clean it thoroughly with an alcohol based solvent.

1. Shut off the engine and remove the key.

2. Position speed select lever in the first forward gear.

WARNING: Fuel and its vapors are extremely flammable, which could cause burns or fire resulting in death of serious injury.

- When performing maintenance that requires the unit to be tipped, the fuel tank must be empty or fuel can leak out and result in a fire or explosion.

3. Stand the snowthrower up on the auger housing end.

Note: When the crankcase is filled with oil, do not leave the snowthrower standing up on the auger housing for an extended period of time.

4. Remove screws (A, Figure 17) and bottom panel (B).

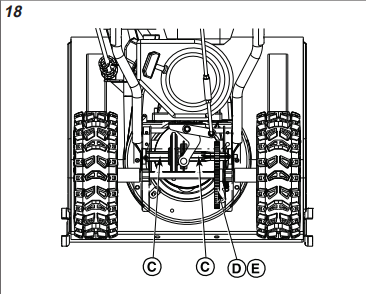

5. Wipe the hex shaft (C, Figure 18) with motor oil, before storage and at the beginning of each season.

6. Lubricate the sprocket (D) and chain (E) with motor oil, before storage and at the beginning of each season.

7. Install the bottom panel (B, Figure 17) and screws (A)

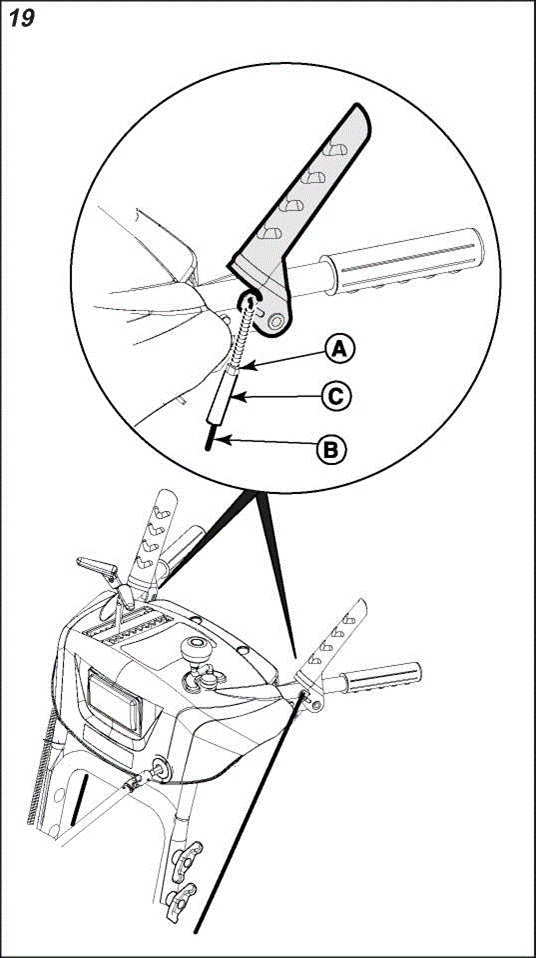

Adjusting the Auger and Traction Cable

DANGER^: The snowthrower contains a rotating auger and impeller to throw snow. Fingers or feet can quickly become caught in the auger or impeller resulting in traumatic amputation or severe laceration.

- Over-tightening the auger and impeller cable may cause the auger and impeller to rotate even if the auger control is not pressed down.

- Over-tightening the traction cable may cause drive to engage even if the traction control is not pressed down.

Follow the adjustment procedure to ensure the cables are not over-tightened.

The auger and impeller should rotate only when the auger control is engaged and must stop within 5 seconds when the auger control is released. If the auger and impeller do not rotate or do not stop as described, adjust the control cable or contact an authorized service dealer to adjust the control cable.

The unit should only move when the traction control is engaged and must stop immediately when the traction control is released. If the unit does not stop as described, adjust the control cable or contact an authorized service dealer to adjust the control cable.

1. Shut off the engine and remove the key.

2. Loosen jam nut (A, Figure 19).

3. Hold control cable (B) to keep it from rotating.

Note: The cable should not rotate while making adjustment.

4. Turn collar (C) to remove slack but do not over-tighten.

5. Tighten jam nut.

6. After adjustment, check the operation of the auger and traction controls, as well as the Free Hand feature using the tests below:

Test 1 -Auger/lmpeller Control

With the engine running:

- Press down on the auger control lever. (The auger/impeller should rotate)

- Release the auger control lever. (The auger/impeller must stop within 5 seconds)

Test 2 - Traction Drive Control

With the engine running and speed control in 1st gear:

- Press down on the traction control lever. (The unit should move toward)

- Release the traction lever. (The unit must stop)

Test 3 - Free Hand Feature

With the engine running:

- Engage the auger and traction control levers, then release the auger control lever. (Both controls should remain engaged)

- Next, release the traction control lever. (Both controls must release)

7. If the unit does not operate as described, DO NOT use it. Contact an authorized service dealer to have the unit inspected and adjusted or repaired.

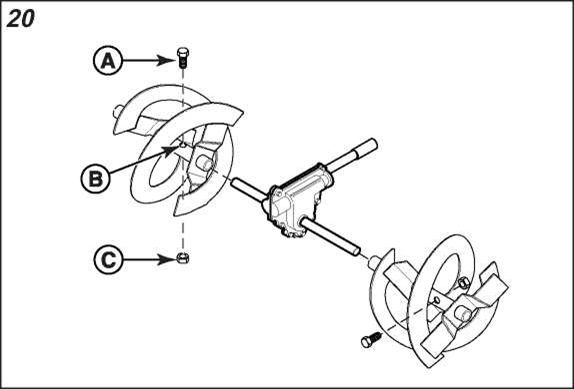

Replacing the Auger Shear Bolt

DANGER  : The snowthrower contains a rotating auger and impeller to throw snow. Fingers or feet can quickly become caught in the auger or impeller resulting in traumatic amputation or severe laceration.

: The snowthrower contains a rotating auger and impeller to throw snow. Fingers or feet can quickly become caught in the auger or impeller resulting in traumatic amputation or severe laceration.

- Turn the engine OFF, wait for all moving parts to stop, and remove the engine key before performing any maintenance or repairs.

1. Shut off the engine and remove the engine key.

2. Remove the existing shear bolt (A, Figure 20) and locknut (C).

3. Add grease at the auger grease fittings, (if equipped). Spin the auger to lubricate the auger shaft.

Note: Some models are not equipped with grease fittings and are exempt from this step.

4. Align the bolt holes. Install the new shear bolt through the auger shaft (B). Secure with the locknut (C).

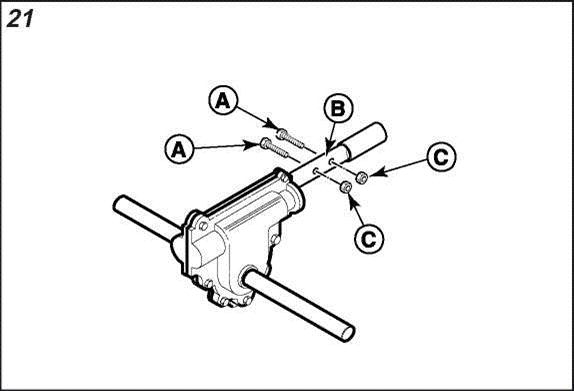

Replacing the Impeller Shear Bolt

DANGER  : The snowthrower contains a rotating auger and impeller to throw snow. Fingers or feet can quickly become caught in the auger or impeller resulting in traumatic amputation or severe laceration.

: The snowthrower contains a rotating auger and impeller to throw snow. Fingers or feet can quickly become caught in the auger or impeller resulting in traumatic amputation or severe laceration.

- Turn the engine OFF, wait for all moving parts to stop, and remove the engine key before performing any maintenance or repairs.

- Shut the engine off and remove the engine key.

- Remove the existing shear bolt (A, Figure 21) and locknut (C) from impeller shaft (B).

- Align the bolt holes. Install the replacement shear bolt through the impeller shaft. Secure with the locknut.

Checking Tire Pressure

WARNING

Explosion hazard

Over-inflation of tires may cause them to explode, which could result in serious injury.

Do not inflate the tires above the maximum pressure.

Tire pressure should be checked periodically. Recommended tire pressure varies by tire manufacturer. A good rule of thumb is to inflate the tire up to, but not exceeding, the “Max Inflation” stamped on the side-wall of the tire.

Storage

Storing for Off-Season

At the end of the season, or whenever the unitwill be stored for 30 days or more, follow the storage checklist below.

WARNING  : Gasoline is highly flammable and its vapors are explosive. Fumes may travel to a distant ignition source and an explosion and/or fire may result.

: Gasoline is highly flammable and its vapors are explosive. Fumes may travel to a distant ignition source and an explosion and/or fire may result.

- If there is fuel in the tank, do not store the unit indoors or in a poorly ventilated area where fumes could reach sparks, open flames, pilot lights, heat, and other ignition sources

Engine:

Fuel can become stale when stored more than 30 days. Stale fuel can cause acids and gum deposits to form in the fuel system and the carburetor. To keep fuel fresh, add Briggs & Stratton Advanced Formula Fuel Treatment and Stabilizer.

- There is no need to drain the fuel from e engine if a stabilzer is added according to instructions. Run the engine for 2 minutes to circulate the stabilzer throughout the fuel system. If no stabilizer is added, the fuel must be drained from the engine into an approved container. Then run the engine until it stops from lack of fuel.

- While the engine is still warm, change the oil. See Changing the Engine Oil.

Snowthrower:

- Thoroughly clean the unit and ensure all nuts, bolts, and screws are securely fastened.

- Inspect all visible moving parts for damage, breakage, and wear. Replace if necessary.

- Lubricate the control lever linkages, chute and deflector, auger assembly, and drive wheel axles. See Maintenance and Adjustments.

- For any rusted or chipped paint surfaces, sand lightly and apply touch-up paint.

- For unpainted or bare metal surfaces, apply a rust preventative product.

- Store the unit indoors and cover it. If stored outdoors, cover it with a heavy tarpaulin.

Returning the unit to Service:

- Have authorized service dealer perform annual maintenance tasks. See Maintenance Schedule.

- Check the engine oil level and add oil, if necessary.

- Fill the fuel tank with a fresh, clean fuel.

- Check tire pressures.

- Ensure all guards, shields, and covers are in place. Ensure all fasteners are tight.

- Check the auger and impeller control, and the traction drive control.

Troubleshooting

Troubleshooting Chart

Perform the inspection or repair as indicated in the Troubleshooting Chart.

| Problem | Look for | Remedy |

Auger does not stop within 5 seconds after auger control lever is released. | Auger control cable out of adjustment. | See Adjusting the Auger and Traction Cable. |

Discharge chute or deflector does not work. | Discharge chute or deflector out of adjustment or needs lubrication. | Adjust and/or lubricate control linkage. |

Scraper bar does not clean hard surface. | Skid shoes and scraper bar improperly adjusted. | See Adjusting the Skid Shoe Height. |

Unit does not propel itself. | Traction control cable out of adjustment. | See Adjusting the Auger and Traction Cable. |

Engine does not start. | Key is in OFF position. | Turn key to ON position. |

| Primer button not pressed (cold engine). | Press primer button twice and restart. | |

Fuel shut-off valve (if equipped) is in CLOSED position. | Turn valve to OPEN position. | |

Out of fuel. | Fill fuel tank. | |

Choke turned to OPEN/RUN (cold engine). | Turn choke to CLOSED/START, set throttle to FAST. | |

| Engine flooded | Move the choke to OPEN/RUN position, move throttle to FAST position, and crank until the engine starts. | |

Engine starts hard or runs poorly. | Water in fuel, or old fuel. | Fill with fresh fuel. |

Fuel cap vent is blocked. | Clear vent or replace fuel cap. | |

Excessive vibration. | Loose parts or damaged impeller. | Stop engine immediately. Tighten all hardware. If vibration continues, have the unit serviced by an Authorized Dealer |

Snowthrower does not stop when traction control lever is released. | Traction control cable out of adjustment. | See Adjusting the Auger and Traction Cable. |

Unit does not discharge snow. | Auger control cable out of adjustment. | See Adjusting the Auger and Traction Cable. |

Broken auger shear bolt. | See Replacing the Auger Shear Bolt. | |

Broken impeller shear bolt. | See Replacing the Auger Shear Bolt. | |

Discharge chute clogged. | STOP THE ENGINE! Ensure that the auger and impeller have stopped rotating. Use a clean-out tool to remove snow from the discharge chute. Never clear a clogged discharge chute with your hands! See Clearing a Clogged Discharge Chute. | |

Foreign object lodged in auger. | STOP THE ENGINE! Ensure that the auger and impeller have stopped rotating. Use a clean-out tool to remove foreign object. Never clear a lodged object with your hands! See Clearing a Clogged Discharge Chute. |

For all other issues, contact an authorized service dealer.

Specifications

Specification Chart

The spark ignition system on this snowthrower complies with Canadian standard ICES-002.

Item | Model 130000 | Model 150000 |

Armature air gap | .010 - .014 inch (,25 - ,36 mm) | .010 - .014 inch (,25 - ,36 mm) |

Intake Valve Clearance | .004 - .006 inch (,10 - ,15 mm) | .004 - .006 inch (,10 - ,15 mm) |

Exhaust Valve Clearance | .006 - .008 inch (,15 - ,20 mm) | 009-.011 inch (,23-,28 mm) |

Oil Capacity | 18-20 oz(,54- ,59 L) | 18 - 20 oz (,54-,59 L) |

Sparkplug gap | 030 inch (,76 mm) | .030 inch (,76 mm) |

Engine power will decrease 3.5% for every 1,00 feet (300 meters) above sea level and 1 % for every 10 degrees F (5.6 degrees C) above 77 Degrees F (25 Degrees C). The engine will operate satisfactorily at an angle up to 15 degrees.

Power Ratings

The gross power rating for individual gasoline engine models is labeled in accordance with SAE (Society of Automotive Engineers) code J1940 Small Engine Power & Torque Rating Procedure, and is rated in accordance with SAE J1995. Torque values are derived at 2600 RPM for those engines with “rpm” called out on the label and 3060 RPM for all others; horsepower values are derived at 3600 RPM. The gross power curves can be viewed at. Net power values are taken with exhaust and air cleaner installed whereas gross power values are collected without these attachments. Actual gross engine power will be higher than net engine power and is affected by, among other things, ambient operating conditions and engine-to-engine variability. Given the wide array of products on which engines are placed, the gasoline engine may not develop the rated gross power when used in a given piece of power equipment. This difference is due to a variety of factors including, but not limited to, the variety of engine components (air cleaner, exhaust, charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating conditions (temperature, humidity, altitude), and engine-to-engine variability. Due to manufacturing and capacity limitations, Briggs & Stratton may substitute an engine of higher rated power for this engine.

See other models: 1697184 1696737 1696610 30554 30740