Loading ...

Loading ...

Loading ...

Part number 550-142-054/1211

GV90+ gas-fired water boiler — Boiler Manual

20

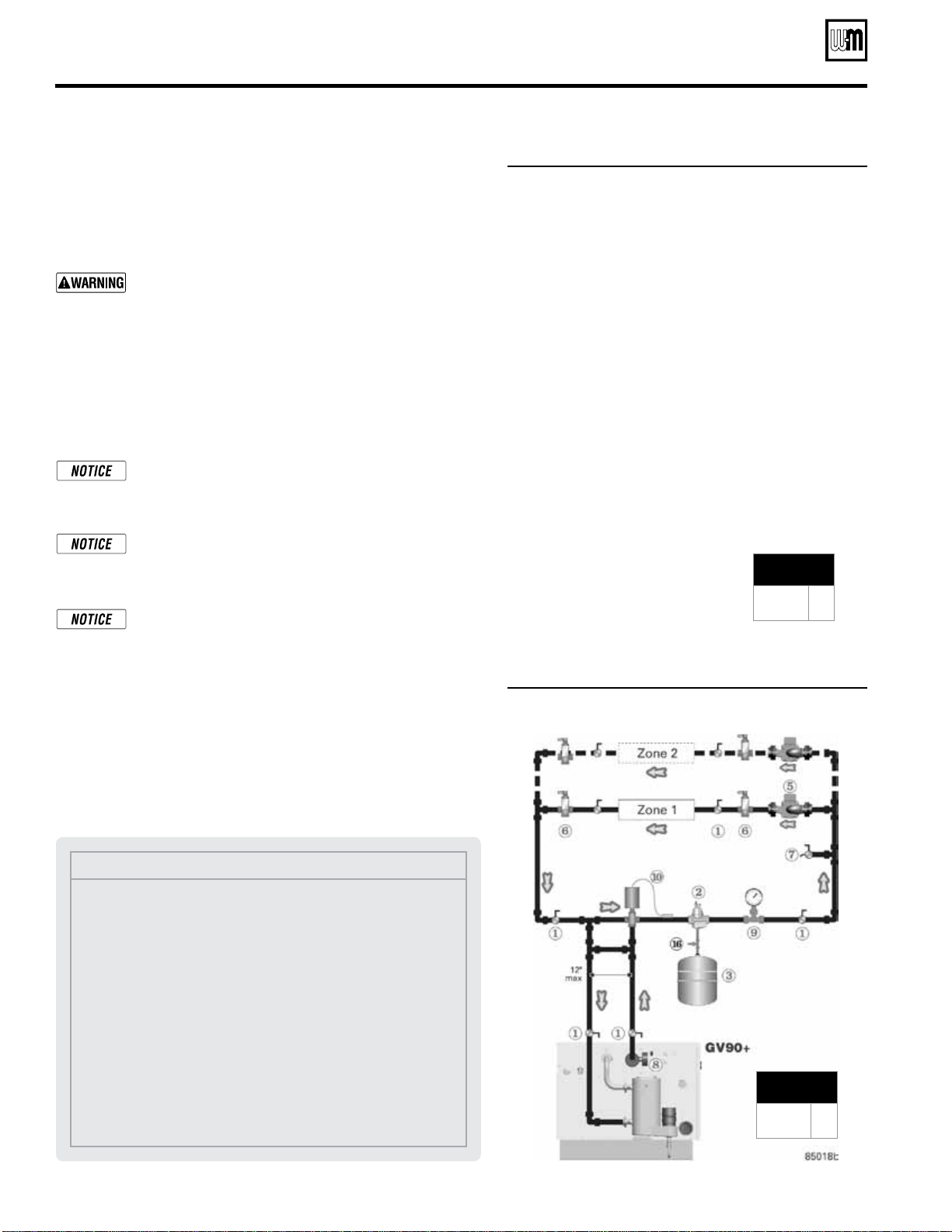

Figure 23 Auto system supply temp regulation —

zone valve zoning

Figure 24 Auto system supply temp regulation —

circulator zoning

Multi-zone radiant heating system

Multi-zone systems require automatic regulation of the system sup-

ply temperature because of widely varying load conditions. Figure 23

(zone-valve zoning) and Figure 24 (circulator zoning) show suggested

piping for these systems.

Provide an automatic temperature control valve or

motor-operated valve which can be adjusted for the

desired supply water temperature. This is required to

protect the radiant system from excessive temperature.

Zone-valve zoning — The suggested piping uses a separate circulator

for system circulation to provide the higher flow typical of radiant

heating systems and to assure good temperature distribution in the

system when the return water temperature is low.

Circulator zoning — The GV90+ internal circulators must not be

removed. Provide a separate circulator for each zone.

Balancing, when required

—

Substitute a memory-stop

valve for one of the isolation valves in each zone to use

the memory-stop valve for balancing flow as well as

isolation.

Zoning with zone valves —

Provide a separate 24-volt

transformer to power the zone valves. Size the trans-

former to handle the total rated load of all connected zone

valves. Alternatively, use a zone valve zone controller.

Zoning with circulators — The GV90+ internal system

circulator cannot be removed from the boiler for use as

one of the zone circulators. It must remain as shipped

from the factory to allow proper flow control inside the

boiler. You will need a circulator for each zone. Provide

circulator relays or circulator zone controller. The sys-

tem circulator must be supplied by the installer.

Outdoor reset

Apply Figure 23 or Figure 24 for any system intended for outdoor reset

of the supply water temperature. Use a motor-operated three-way valve

and an outdoor reset temperature control system.

MINIMUM

Boiler loop pipe size

GV90+3/4

GV90+5/6

1”

1¼”

MINIMUM

Boiler loop pipe size

GV90+3/4

GV90+5/6

1”

1¼”

Legend

1 Isolation valves

2 Automatic air vent (with diaphragm-type expansion tank), or

connect to tank fitting (closed-type expansion tank).

3 Diaphragm- or bladder-type expansion tank, if used (For closed-

type expansion tank, pipe from top of air separator to tank fitting

as in Figure 15, page 14.)

4 Zone valve

5 System or zone circulator

6 Flow/check valve

7 Hose bibb purge valve

8 Boiler pressure/temperature gauge

9 System supply temperature gauge

10 Supply temperature automatic mixing valve

11 Differential pressure by-pass valve

16 Cold water fill line — see Figure 15, page 14 for typical components

Install water piping (continued)

Loading ...

Loading ...

Loading ...