Loading ...

Loading ...

Loading ...

(cont’d)

Adjustments for Competition 119

Front Suspension Adjustments

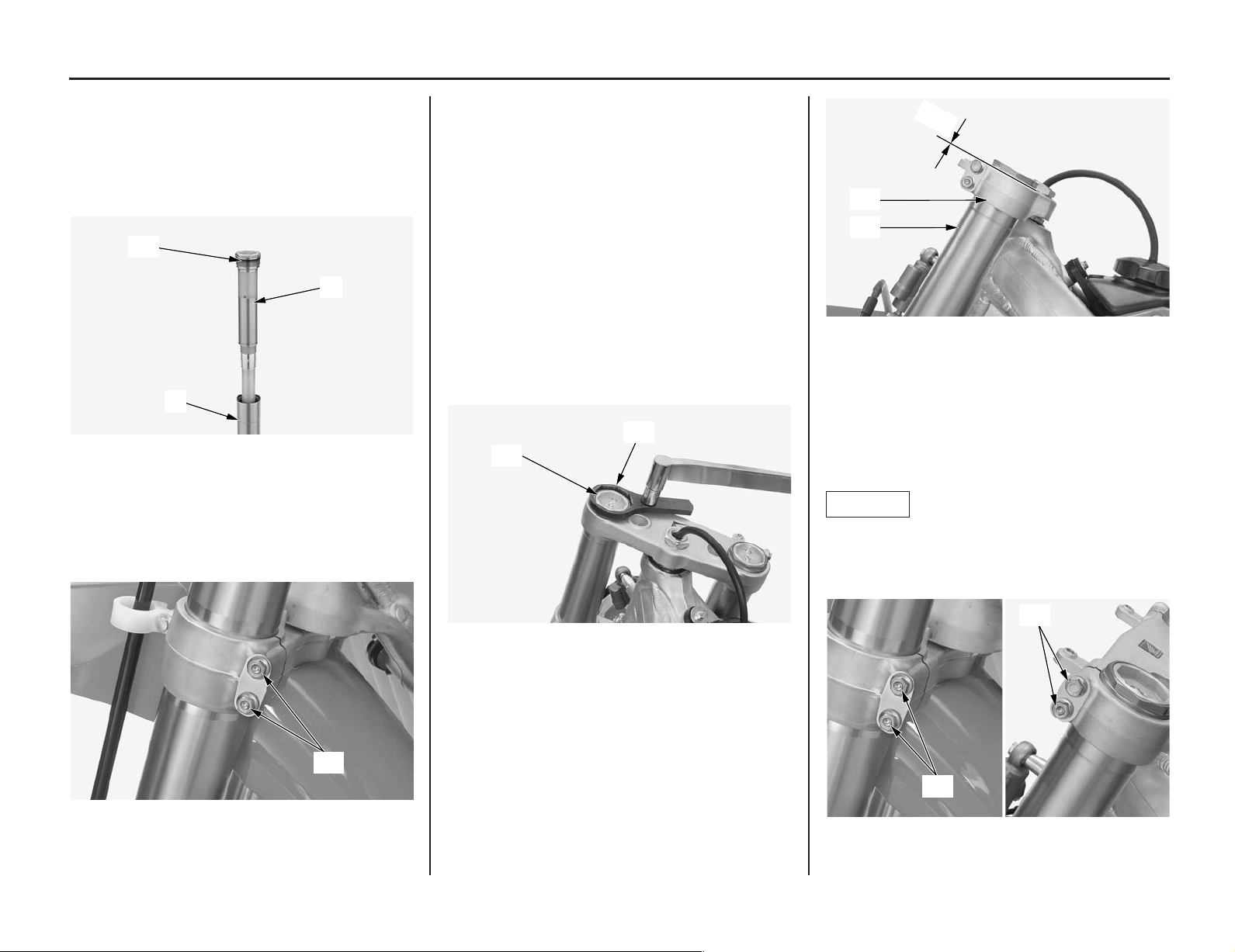

14. Install a new O-ring (13) on the fork damper

assembly (5). Apply the recommended fork

oil to the O-ring.

15. Pull up the fork assembly (1) slowly and

install the fork damper assembly (5) into the

outer tube.

(1) fork assembly (13) O-ring

(5) fork damper assembly

16. Insert both fork legs into the fork clamps.

Tighten the fork bridge lower pinch bolts (14)

to the specified torque:

15 Ibf·ft (20 N·m, 2.0 kgf·m)

(17) outer tube (18) top bridge

19. Tighten the fork bride lower pinch bolts (14)

to the specified torque:

15 Ibf·ft (20 N·m, 2.0 kgf·m)

20. Tighten the fork bridge upper pinch bolts (19)

to the specified torque:

16 Ibf·ft (22 N·m, 2.2 kgf·m)

Over-tightening the pinch bolts can deform the

outer tubes. Deformed outer tubes must be

replaced.

NOTICE

(14) fork bridge lower (19) fork bridge upper

pinch bolts pinch bolts

(13)

(5)

(1)

(14)

(19)

(14)

(14) fork bridge lower pinch bolts

17. Tighten the fork damper (15) to the specified

torque using the lock nut wrench (16).

Actual:

22 lbf·ft (30 N·m, 3.1 kgf·m)

Torque wrench scale reading:

20 Ibf·ft (27 N·m, 2.8 kgf·m), using a 20 in

(50 cm) long deflecting beam type torque

wrench.

• Lock nut wrench 070MA-MEN0100

When using the lock nut wrench, use a 20 in (50

cm) long deflecting beam type torque wrench.

The lock nut wrench increases the torque

wrench’s leverage, so the torque wrench reading

will be less than the torque actually applied to the

fork damper.

(15)

(16)

(15) fork damper (16) lock nut wrench

18. For ease of releasing air pressure after the

forks are installed, loosen the fork bridge

lower pinch bolts and position the outer tubes

so that the fork air pressure release screws are

in front of the compression damping adjusters.

Align the top of the outer tube (17) with the

top surface of the top bridge (18).

(17)

(18)

Align

Loading ...

Loading ...

Loading ...