Loading ...

Loading ...

Loading ...

SECTION 5 sE.vmcER'sTEC..I.FO.MATIO.

L !

, i ii ii

5C. TROUBLESHOOTING

m,i i,i

a, If it does not move into fill, valve motor is inopera-

tive, Check all wiring and connections

b. If water does not enter tank, see "Quick-Check

Troubleshooting," page 26.

- After fill. press [] to move softener l - P }

into brining. A slow flow of water to

drain begins Verify brine draw from

brine tank, See flow rates on page 23.

NOTE: WHILE IN MANUAL ADVANCE, THE TIME

DISPLAY WILL AUTOMATICALLY RETURN TO THE

PRESENT TIME IF A BUTTON IS NOT PRESSED

WITHIN 4 MINUTES.

c. if softener does not draw brine_see "Quick-

Check Troubleshooting,".

NOTE: Be sure a salt bridge is not preventing water

with salt contact.

- Again press [] to move softener into [ - P

backwash Look for a fast flow of wa-

r

ter from drain hose See flow rates, [

i i

page 23

d. An obstructed flow indicates a plugged top distri-

butor, backwash flow plug, or drain hose.

- Press [] to move softener into fast

rinse. Again look for fast drain flOWr

Allow softener to rinse for a few min-

utes to flush out any brine remaining

in resin tank from brining cycle test

-To return softener to service,

press [] .

4. Press I_ to display 18:88

5. Press [] to return present time

and day

[ -P]

[ --I

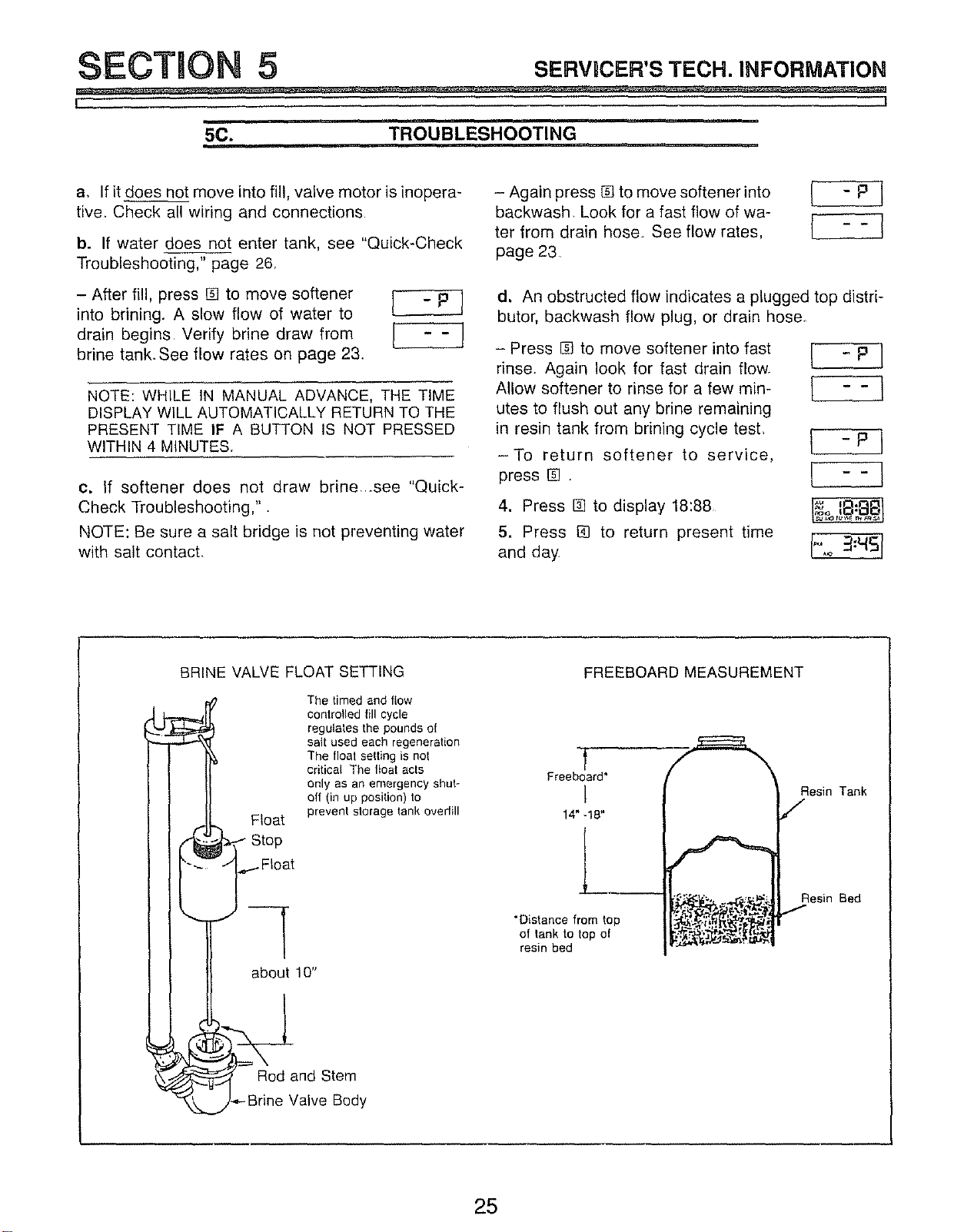

BRINE VALVE FLOAT SETTING

Float

_Stop

.,,I Float

about 10"

The timed and flow

controlled fill cycle

regulates the pounds of

salt used each regeneration

The float selting is not

critical The float acts

anly as an emergency shut*

aft (in up posilion) to

prevent storage tank ovedill

_( Rod and Stem

J-_-Brine Valve Body

FREEBOARD MEASUREMENT

Freeboard*

!

14" -!8"

"Distance from top

of lank to top of

resin bed

Resin Tank

Resin Bed

25

Loading ...

Loading ...

Loading ...