Loading ...

Loading ...

Loading ...

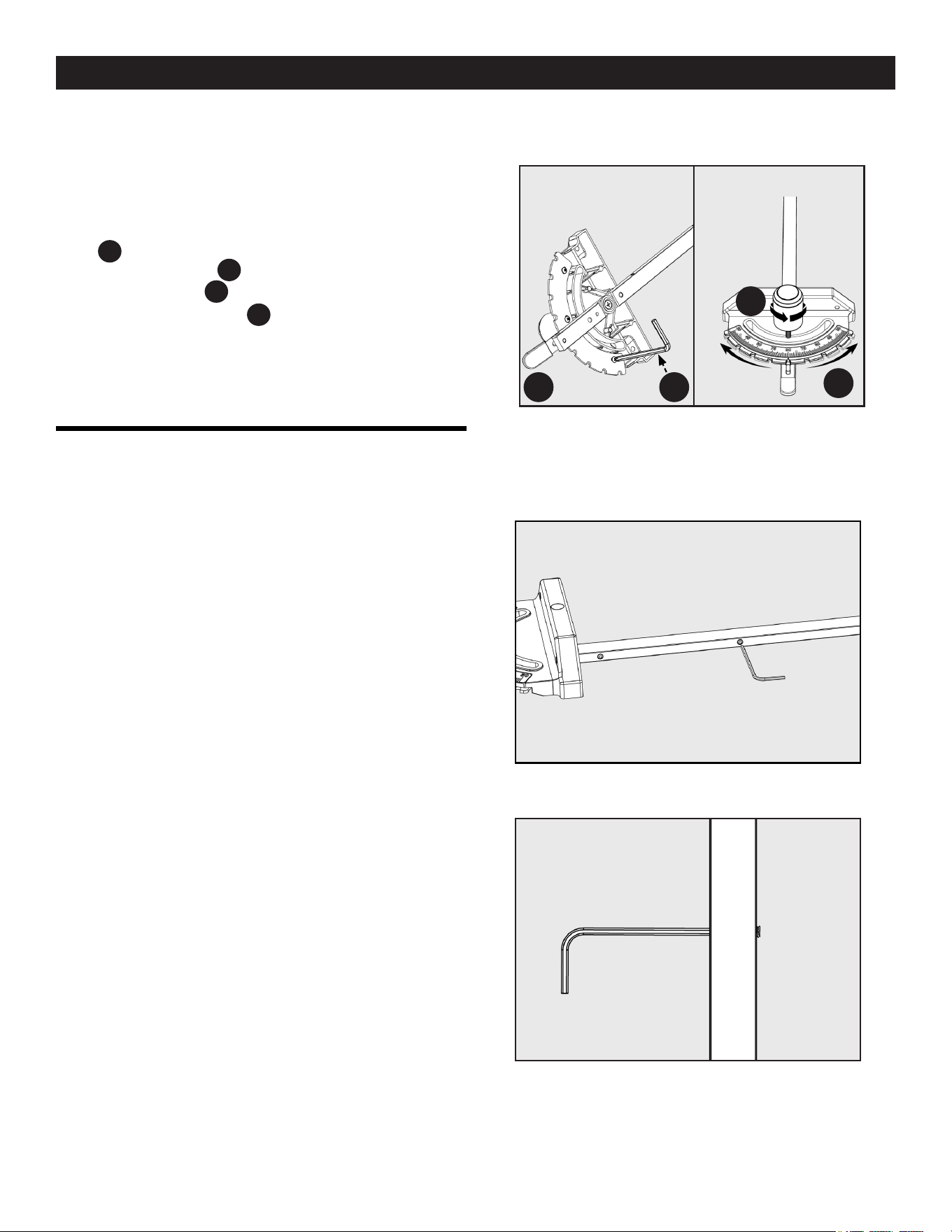

Figure 28

Figure 29

Figure 30

PC6 HP23

A

B

ADJUSTING THE MITER GAUGE

FITMENT

To adjust the tment between the miter gauge bar and the miter

slot:

1. Use a 3/32 inch Allen wrench on any of the three set

screws located on the side of the bar. See Figure 29 and

30.

2. To remove any side-to-side movement between the miter

gauge bar and miter gauge table slot adjust the three small

set screws found along the length of the miter gauge bar.

NOTE: The set screws should extend just beyond the side of the

bar.

ADJUSTING THE MITER GAUGE

SCALE

Use a combination square to check bar to head angle. If miter

gauge bar is not square to miter gauge head, then adjustment is

necessary. For adjustment, see below:

Use the supplied 3/16 inch two-way Allen wrench L Shape

HP23

to loosen the three Phillip screws located in the back

of the miter gauge

PC6

, seen in Figure 28 .

1. Loosen the knob

A

, seen in Figure 28.

2. Adjust the detent plate

B

so that the indicator measures

the correct angle, seen in Figure 28.

3. Once lined up, re-tighten the knob, and Phillip screws back

in place.

MAKING ADJUSTMENTS

28

Loading ...

Loading ...

Loading ...