Loading ...

Loading ...

Loading ...

OPERATION

MOUNTING DOVETAIL TEMPLATE

FOR SAFE OPERATION AND PROPER CONTROL,

YOUR DOVETAIL TEMPLATE MUST BE MOUNTED

TO A WORKBENCH OR TABLE. If desired, it can be

clamped to a workbench with "C" clamps, or it can

be mounted onto a 3/4 inch piece of plywood for

mobility. See Figures 5 & 6.

1. Clamp your dovetail template to a workbench or

tab}e with "C" clamps as shown in Figure 5. It can

then be easily removed upon completion for easy

storage or changing job sites.

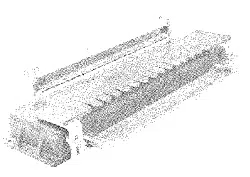

2. A second, more preferred, method would be to

mount your dovetai_ template onto a piece of 3/4

inch plywood approximately six inches wide and

twenty-four inches long. See Figure 6. Position

front of base flush with the front and centered

with the ends of the board, then insert four fiat

head wood screws through holes in the base and

secure firmly into plywood. Your dovetail template

(with wooden base) may then be clamped securely

to workbench or table with "C" clamps or other

holding apparatus. Here again, it can be easily

removed upon completion for easy storage or

changing job sites.

INSTALLING TEMPLATE GUIDE

RUSHING AND CUTTER

Two template guide bushings are supplied with your

dovetail template. They are used to guide your router

in and out of the fingers of the comb-shaped

template. The 5/16 inch bushing is used when mak-

ing 1/4 inch dovetails, while the 7/16" bushing is us-

ed when making 1/2" dovetails.

1"O AVOID POSSIBLE SERIOUS PERSONAL

INJURY, UNPLUG YOUR ROUTER WHILE

ASSEMBLING PARTS OR MAKING

ADJUSTMENTS

1. Attach guide bushing directly to the inside of the

subbase, See Figure 7. NOTE: It is not necessary

to remove subbase while attaching guide bush-

ing, but be sure collar section is turned facing

away from the router motor.

2. Secure bushing to the subbase with the 3 screws

supplied.

3. Insert dovetail cutter through guide bushing and

into collet at least 1/2 inch, If 1/2 inch engage-

ment does not exist, lower the router motor in the

router base until collet nut is approximately 1/8

inch clear of guide bushing.

4. Tighten clamping wing nut securely before

attempting to center cutter inside guide bushing.

If clamping wing nut is not tighL the router motor

will be loose and wobble inside router base while

adjustments are being made.

5. Visually center the cutter with the inside diameter

of the guide bushing, then tighten the collet nut

securely. NOTE: When centering cutter in guide

bushing, adjustments can be made by loosening

the screws holding the subbase to the router

and!or loosening the screws holding the guide

bushing to the router.

6, Tighten all screws securely.

Fig. 5

WOOD SCREWS

"C" CLAMP

PLYWOOD

r_

Fig. 6

SCREWS COLLAR

DOVEfAIL CUTTER Fig. 7

Page 4

Loading ...

Loading ...

Loading ...