Loading ...

Loading ...

Loading ...

TP-7092 2/21 69Section 4 Scheduled Maintenance

Refer to this section for general battery information and

maintenance. Also consult the battery manufacturer’s

instructions for battery maintenance.

All generator set models use a negative ground with a

12-volt engine electrical system. Consult the generator

set nameplate for the engine electrical system voltage.

Consult the generator spec sheet for battery size and

capacity recommendations for replacement purposes.

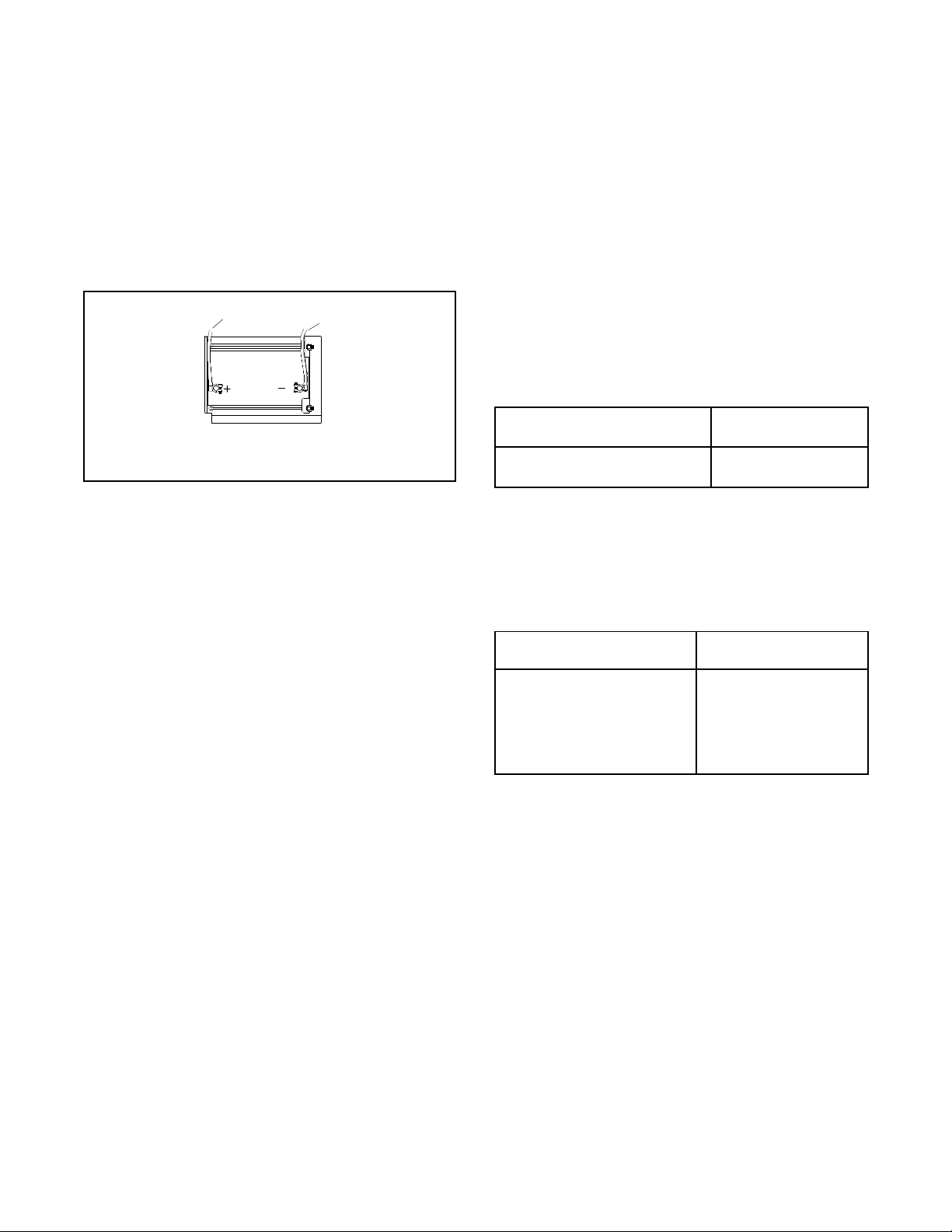

Wiring diagrams provide battery connection

information. See Figure 4-10 for typical battery

connections.

EZ-273000-J

1

2

1. To positive (+) terminal on starter solenoid.

2. To ground (- ) terminal on or near starter motor.

Figure 4-10 12-Volt Engine Electrical System Single

Starter Motor, Typical Battery Connection

4.7.1 Cleaning the Battery

Clean the battery and cables and tighten battery

terminals using the service schedule recommendations.

To prevent corrosion, maintain tight, dry electrical

connections at the battery terminals. To remove

corrosion from battery terminals, disconnect the cables

from the battery and scrub the terminals with a wire

brush. Clean the battery and cables with a solution of

baking soda and water. After cleaning, flush the battery

and cables with clean water and wipe them with a dry,

lint-free cloth.

After reconnecting the battery cables, coat the battery

terminals with petroleum jelly, silicone grease, or other

nonconductive grease.

4.7.2 Checking Electrolyte Level

Check the electrolyte level of batteries with filler caps

monthly. Remove filler caps and verify that electrolyte

level reaches bottom of filler holes. Refill as necessary

with distilled water. DO NOT add fresh electrolyte.

Tighten all filler caps. If water is added during freezing

temperatures, run the generator set for 20- 30 minutes

to mix the electrolyte and water to prevent battery

damage from freezing.

4.7.3 Checking Specific Gravity

Use a battery hydrometer to check the specific gravity of

the electrolyte in each battery cell. While holding the

hydrometer vertically, read the number on the glass bulb

at the top of the electrolyte level or the number adjacent

to the pointer. If the hydrometer used does not have a

correction table, use the correction factors in

Figure 4-13. Determine specific gravity and electrolyte

temperature of battery cells. Locate temperature in

Figure 4-13 and adjust the specific gravity by the

amount shown.

The battery is fully charged if the specific gravity is 1.260

at an electrolyte temperature of 80°F (26.7°C). The

difference between specific gravities of each cell should

not exceed 0.01. Charge the battery if the specific

gravity is below 1.215 at an electrolyte temperature of

80°F (26.7°C). See Figure 4-11.

Specific Gravity,

Corrected to

80

°

F (26.7

°

C)

Battery

Condition

Below 1.215 Needs charging

1.260 Fully charged

Figure 4-11 Specific Gravity Interpretation

Some battery testers have four or five beads in the test

tube. Draw electrolyte into the tube as performed with

the battery hydrometer described previously. Use the

manufacturer’s instructions. Figure 4-12 interprets

typical test results.

Number of Floating Beads

Battery

Condition

5 Overcharged

4 Fully charged

3 Good charge

1 or 2 Low charge

0 Dead battery

Figure 4-12 Bead-Type Test Interpretation

Loading ...

Loading ...

Loading ...