Loading ...

Loading ...

Loading ...

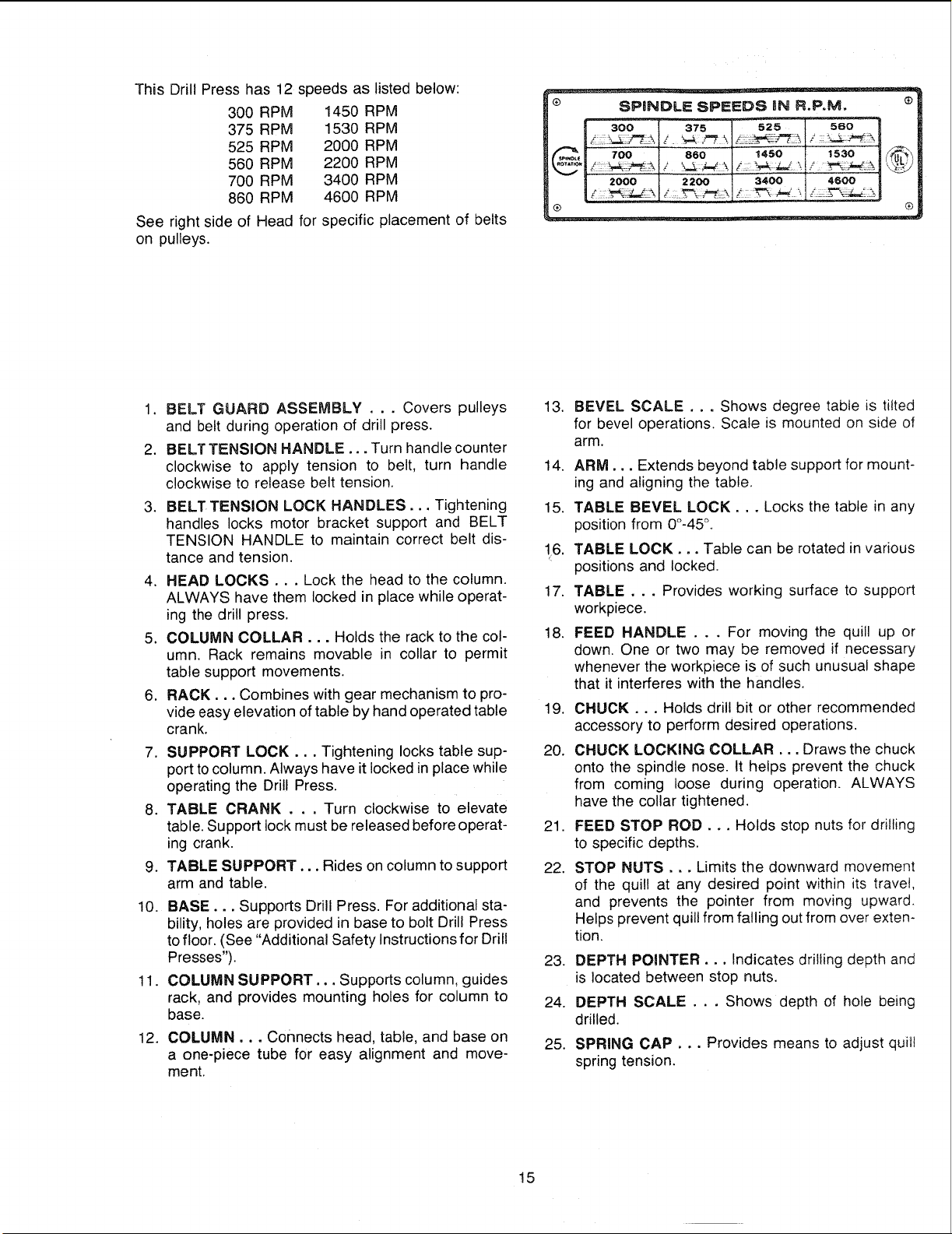

This Drill Press has 12 speeds as listed below:

300 RPM 1450 RPM

375 RPM 1530 RPM

525 RPM 2000 RPM

560 RPM 2200 RPM

700 RPM 3400 RPM

860 RPM 4600 RPM

See right side of Head for specific placement of belts

on pulleys.

SPINDLE SPEEDS iN R.P, Mo

300 375

_._ 700 860

2000 2200

®

-- 5zs sac

1450 1530

4600

®

1. BELT GUARD ASSEMBLY . . . Covers pulleys

and belt during operation of drill press.

2. BELT TENSION HANDLE... Turn handle counter

clockwise to apply tension to belt, turn handle

clockwise to release belt tension.

3. BELT TENSION LOCK HANDLES... Tightening

handles locks motor bracket support and BELT

TENSION HANDLE to maintain correct belt dis-

tance and tension.

4. HEAD LOCKS... Lock the head to the column.

ALWAYS have them locked in place while operat-

ing the drill press.

5. COLUMN COLLAR... Holds the rack to the col-

umn. Rack remains movable in collar to permit

table support movements.

6. RACK... Combines with gear mechanism to pro-

vide easy elevation of table by hand operated table

crank.

7. SUPPORT LOCK... Tightening locks table sup-

port to column. Always have it locked in place while

operating the Drill Press.

8. TABLE CRANK . . . Turn clockwise to elevate

table. Support lock must be released before operat-

ing crank.

9. TABLE SUPPORT... Rides on column to support

arm and table.

10. BASE. o, Supports Drill Press. For additional sta-

bility, holes are provided in base to bolt Drill Press

to floor. (See "Additional Safety Instructions for Drill

Presses").

11. COLUMN SUPPORT... Supports column, guides

rack, and provides mounting holes for column to

base.

12. COLUMN... Connects head, table, and base on

a one-piece tube for easy alignment and move-

ment.

13. BEVEL SCALE... Shows degree table is tilted

for bevel operations. Scale is mounted on side of

arm.

14. ARM... Extends beyond table support for mount-

ing and aligning the table.

!5. TABLE BEVEL LOCK... Locks the table in any

position from 0°-45°.

16, TABLE LOCK... Table can be rotated in various

positions and locked.

17. TABLE... Provides working surface to support

workpiece.

18. FEED HANDLE .. . For moving the quill up or

down. One or two may be removed if necessary

whenever the workpiece is of such unusual shape

that it interferes with the handles.

19. CHUCK o.. Holds drill bit or other recommended

accessory to perform desired operations.

20. CHUCK LOCKING COLLAR... Draws the chuck

onto the spindle nose. It helps prevent the chuck

from coming loose during operation. ALWAYS

have the collar tightened.

21. FEED STOP ROD... Holds stop nuts for drilling

to specific depths.

22. STOP NUTS... Limits the downward movement

of the quill at any desired point within its travet,

and prevents the pointer from moving upward.

Helps prevent quill from falling out from over exten-

tion.

23. DEPTH POINTER... Indicates drilling depth and

is located between stop nuts.

24. DEPTH SCALE . . . Shows depth of hole being

drilled.

25. SPRING CAP.. •Provides means to adjust quill

spring tension.

!5

Loading ...

Loading ...

Loading ...