Loading ...

Read and understand tool labels and all of the operating instructions, safety precautions and

Mos t accidents that result from the operation and maintenance of Nailers are caused by the failure to

observe basic safety rules or precautio ns. An accident can often be avoided by recognizing a po tentially

Basic safety precautions are o utlined in the “SAFETY” section of this Manual and in the sections which

ed by DANGERS

indicates an imminently hazardous situation which, if not avoided, will result in death or serious

indicates a potentially hazardous situation which, if not avoided, could result in death or

indicates a potentially hazardous situation which, if not avoided, may result in minor or

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS

READ ALL THE INSTRUCTIONS

1. OPERATORS AND OTHERS IN WORK AREA MUST WEAR EYE PROTECTION (SAFETY

When operating the Nailer, always wear safety glasses with side sh ields, and make sure others

Safety glasses must conform to the requirements of American National Standards Institute,

The employer must enforce the use of safety glasses by the Nailer operator and others in work area.

Never us e reactive gases such as oxygen, combustible gases or any other bottled gas es as a

ammable

Distractions are able

(1) Stay alert. Focus on your work and use common sense when working with the Nailer. Do

not use the Nail er while tired, after having consumed drugs or alco hol, or while under the

(2) Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep hair, clothing,

Loose clothes, jewelry, or long hair increases the risk of injury to persons as a resu lt of being caught

– Disconnect the Nailer from the air source before making

adjustments, doing Nailer maintenance, clearing jams, touching the Rod, when not in use,

leaving work area, leaving the Nailer outside of the operator's supervision or control, handing

Never attempt to clear a jam or repair the Nailer unless you have disconnected air h ose from the

Nailer. The Nailer should never be left unat tended since people who are not familiar with the Nailer

(5) Do not overreach. Keep proper footing and balance at all times. Proper footin g and balance

enables better control of the Nailer in unexpected situations.

(6) Use safety equipment. A dust mask, non-skid safety shoes and a hard hat must be used for the

applicable conditions.

(7)

WARNING

– Risk of hearing loss. Wear hearing protection.

Hearing protection shall have a Noise Reduction Rating (NRR) determined in accordance with US

Environmental Protection Agency rules that is appropriate for noise exposure.

(8) Always wear head protection.

Head protection shall conform to ANSI Z89.1, "American National Standard for Industrial Head

Protection."

(9) Do not attach the hose or Nailer to yo ur body.

Attach the hose to the structure to reduce the risk of loss of balance if the hose shifts.

(

10

)

WARNING

– Drive Nails into proper work surface only. Do not drive nail into other

nails. This is able to cause the fastener to be de fl ected and hit someone, or cause the Nailer to react

and result in a risk of injury to persons.

3. Nailer use and care

(1) Use clamps or another practical way to secure and support the workpiece to a stable

platform.

Holding the work by hand or against the body is unstable and is able to lead to loss of control.

(2) Do not force the Nailer. Use the correct Nailer for the application. The correct Nailer will do the job

better and safer at the rate for which the Nailer is designed.

(3) Never use Nailer which is defective or operating abnormally. If the Nailer appears to be operating

unusually, making strange noises, or otherwise appears defective, stop using it immediately and

arrange for repairs by a metabo HPT authorized service center.

(4) Connect air hose before nail loading and check the followings.

Check for air leakage and abnormal noise.

Use of the Nailer in an abnormal condition may cause accidents or injuries. If any abnormality is

detected, ask your dealer or metabo HPT authorized service center for repair.

(5) Disconnect the Nailer from the air source before making any adjustments, changing

accessories, or storing the Nailer.

Such preventive safety measures reduce the risk of starting the Nailer unintentionally.

(6) Store the Nailer when it is idle out of reach of children and other untrained persons. A Nailer

is dangerous in the hands of untrained users.

(7) Maintain the Nailer with care. Keep the Nailer Clean and lubricated for better and safer

performance.

(8) Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may aff ect the Nailer's operation.

If damaged, have the Nailer serviced before using. Because of high air pressure in the Nailer, cracks

in the surface are dangerous. To avoid this, do not drop the Nailer or strike the Nailer against hard

surfaces; and do not scratch or engrave signs on the Nailer. Many a ccidents are caused by poorly

maintained Nailers. There is a risk of bursting if the Nailer is damaged.

(9) Do not use the Nailer that is not in proper working order. Tags and physical segregation

shall be used for control.

(10)

Use only accessories that are identifi ed by metabo HPT for the specifi c Nailer. Use of an

accessory not intended for use with the specifi c Nailer, increases the risk of injury to persons.

(11)

Be aware of followings when connecting air hose.

Make sure there is no nail in the rod.

Otherwise, a nail may be shot mistakenly, which may result in injury.

Keep the nail outlet pointed downward a nd make sure to keep your body, hands and feet away from

the fi ring head.

Do no t place the rod tip on a table or fl oor.

(12)

Use dedicated nails.

Do no t use any other nails because they may result in injury or malfunction of this Nailer.

(13)

Load nail carefully.

When loading a na il in the rod, hold the nail shaft instead of the tip.

Otherwise, when the Nailer operates mistakenly and injuries as nailing a fi nger may result.

When loading a na il in the rod, make sure it does not press the tip of the driver unit.

If the nail is inserted to the rod excessively, it may press the tip of the driver unit. By this, the Nailer

may operate mistakenly, which may result in injury.

(14)

Be aware of followings when shooting nail holding with fi ngers.

Shoot the nail by placing the nail tip at a target fi rst, and then inserting the rod to the nail head.

If the nail tip is not placed fi rmly or the nail head is fi rstly inserted to the rod, injuries may result when

the nail bounces back or is shot mistakenly.

(15)

Avoid long time nailing operation.

Make sure to fi nish nailing in as short a time as possible. Also, avoid continuous operation and allow

adequate downtime between operations.

4. Service

(1) Tool service must be performed only by qualifi ed repair personnel.

(2) When servicing a Nailer, use only identical replacement parts. Use only authorized parts.

(3) Use only the lubricants supplied with the Nailer or speci fi ed by metabo HPT.

5. Air source

(1) Never connect to an air source that is capable of exceeding 200 psi (13.7 bar 14 kgf/cm

2

) if

a regulator fails.

Over pressurizing the Nailer is able to result in bursting, abnormal

oper ation, breakage of the Nailer or serious injury to persons.

DO NOT EXCEED 100 psi (6.9 bar 7.0 kgf/cm

2

).

Use only clean, dry, regulated compressed air at the rated pressure or within the rated pressure range

as marked on the Nailer.

Always verify prior to using the Nailer that the air source has been adjusted to the rated air pressure

or within the rated air-pressure range.

(2) Never use reactive gases such as oxygen, carbon dioxide, co mbustible gases or any bottled

gas as an air source for the Nailer. Such gases are capable of explosion and serious injury to

persons.

100

psi 100

psi

6. Others

(1) Be careful of hit by the Nailer due to spring back (“recoil”). After driving a nail, the Nailer may

recoil causing it to move away from the work surface.

To reduce risk of injury always manage recoil by:

1) always maintaining control of the Nailer.

2) allow ing recoil to move the Nailer away from work surface.

3) keeping face and body parts away from the Nailer.

(2) Never Use NON relieving coupler on Nailer. If a non relieving coupler is used on the Nailer, the

Nailer can remain charged with air after disconnecting and thus will be able to drive a fastener even

after disconnecting. The Nailer and air hose must have a hose coupling such that all pressure is

removed from the Nailer when the coupling joint is disconnected.

(3) Check Rod before use. Make sure the Rod operates properly, and is not inoperable, disconnected,

or altered. This is because a rod loaded with nails acts as a switch. Never use the Nailer unless the

Rod is operating properly, otherwise the Nailer could drive a fast ener unexpectedly. D o not tamper

with or remove the Rod, or otherwise cause the Rod to become inoperable.

(4) Keep all screws and socket tightly in place. Keep all screws and socket tightly mounted.

Check their condition periodically. Never use the Nailer if parts are missing or damaged.

(5) Do not load fasteners with Rod depressed. When loading fasteners into the Nailer or when

conn ecting the air hose,

1) do not depress the Rod;

2) keep the Nailer pointed downward.

(6) Keep hands and body away from fi ring head during use. Never place your hands or feet closer

than 8 inches (200 mm) from the fi ring head. A serious injury can result if the fasteners are defl ected

by the workpiece, or are driven away fr om the point of entry.

(7) When working close to an edge of a workpiece or at steep angles, or driving fasteners into

thin workpiece use care to minimize chipping, splitting or splinterin g, or free fl ight, ricochet

or piercing of fasteners, which may cause injury .

(8) Never drive fasteners from both sides of a wall at the same time. The fasteners can be driven

into and through the wall and hit a person on the opposite side.

(9) Use extra caution when driving the Nailer into existing walls or other blind areas to prevent

contact with hidden objects or persons on other side (eg., wires, pipes).

(10)

Check for live wires . Avoid the risk of severe electrical shock by checking for live electrical wires

that may be hidden by walls, fl oors or ceilings. Turn off the breaker switch to ensure there are no live

wires.

(11)

Do not lift, pull or lower the Nailer by the hose.

(12)

Handle Nailer correctly. Operate the Nailer according to this Ma nual. Never allow the Nailer to be

operated by children, indiv iduals unfamiliar with its operation or unauthorized personne l.

(13)

Never use Nailer for applications other than those specifi ed in this manual.

(14)

Never modify or alter a Nailer. Doing so may cause it to malfunction and personal injuries may

result.

RESPONSIBILITIES OF EMPLOYER, TOOL OWNER AND TOOL

OPERATOR

1. Ensure that this MANUAL is available to operators and personnel performing maintenance.

2. Train the operator in the safe use of the Nailer as described in this MANUAL.

3. Ensure that only persons who have read and underst and this MANUAL operate the Nailer.

4. Ensure that Nailers are used only when operators and others in work area are wearing EYE

PROTECTION, and other appropriate personal protective equipment such as HEAD, HEARING,

FOOT PROT ECTION.

5. Enfor ce the use of EYE PROTECTION by operators and others in work area.

6. Ensure that Nailers are kept in safe working order as described in this MANUAL.

7. Maintain Nailers properly.

8. Ensure that only qualifi ed personnel shall repair Nailers.

9. Ensure that Nailers that require repair are removed from service and that tags and physical

segregation are used as a means of control.

SAVE THIS MANUAL AND

KEEP IT AVAILABLE FOR OTHERS!

OPERATION

NOTE:

The information contained in this Manual is designed to assist you in the safe operation of the Nailer.

Some illustrations in this Manual may show details or attachments that diff er from those on your own

Nailer.

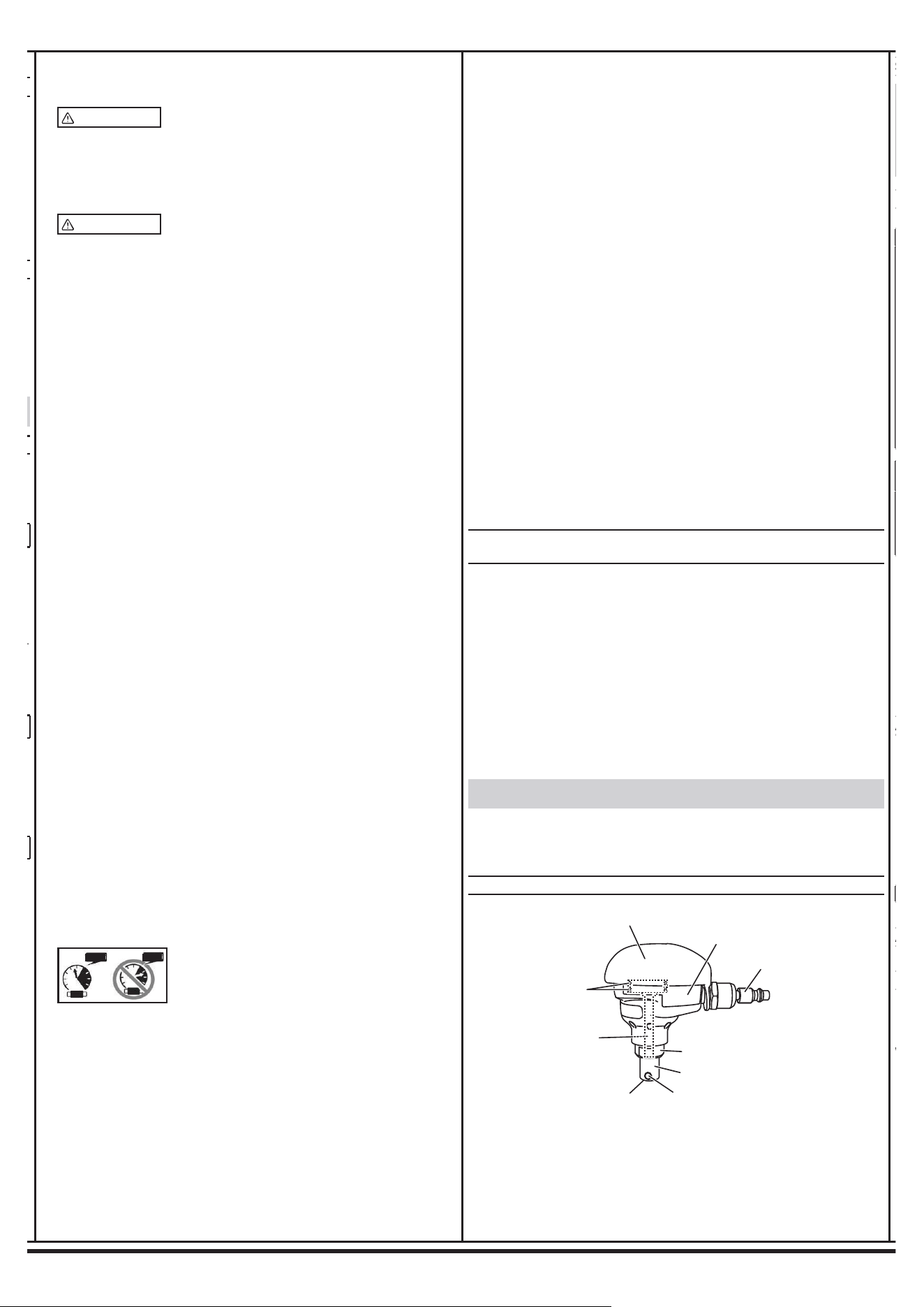

NAME OF PARTS

Driver unit

Grip Rubber

Body

Air Plug

(Free Angle)

Socket

Firing Head (Outlet)

Magnet

Rod

O-Ring

SPECIFICATIONS

ACCESSORIES

APPLICATIONS

WORKING ENVIRONMENT

– 1 – – 3 –

– 2 –

Loading ...

Loading ...

Loading ...