Loading ...

Loading ...

Loading ...

Accu-Steam™ Installation and Owners Manial

MP5004-1202 PAGE 11

THEORY OF OPERATION

INTRODUCTION

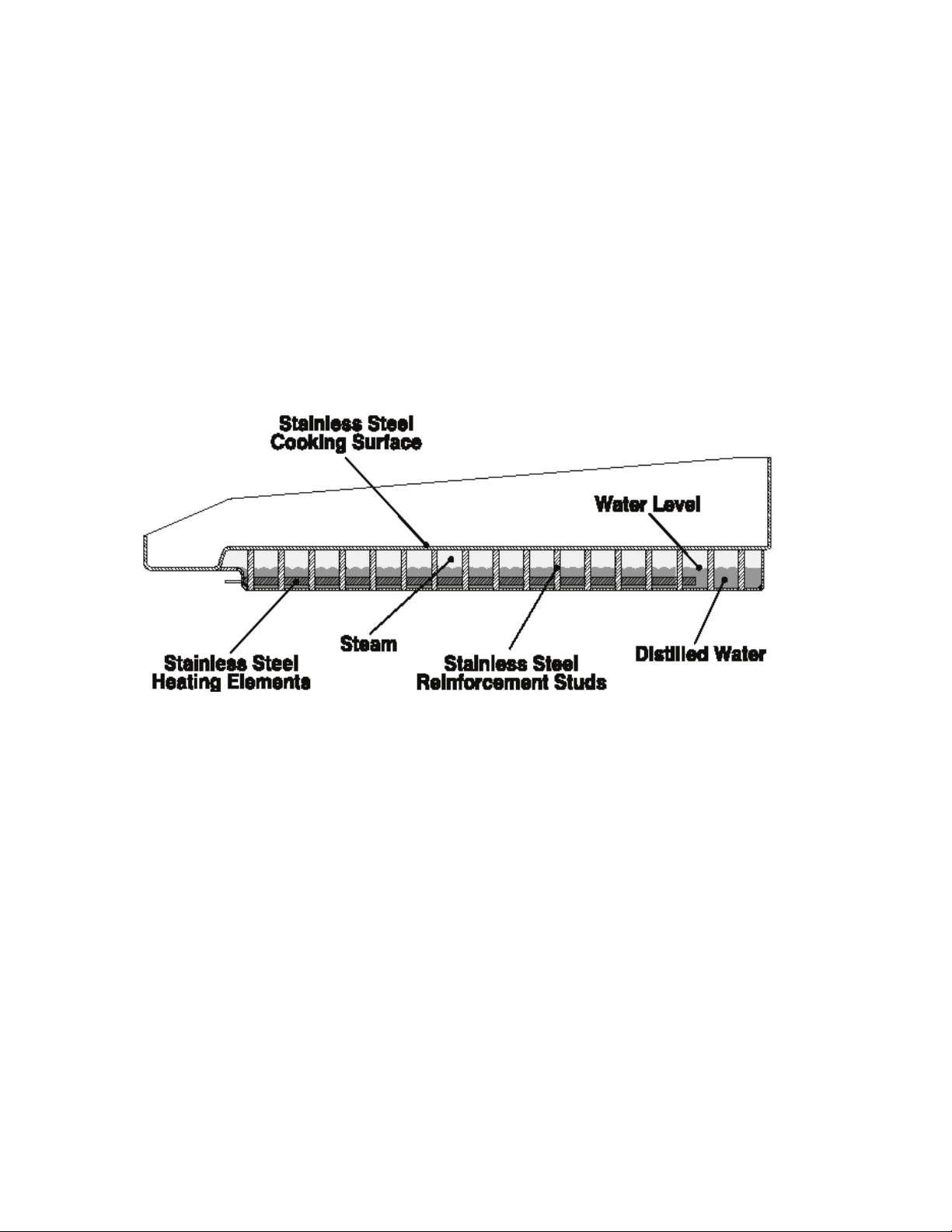

The ACCU-STEAM™ griddle is constructed and uses technology like no other griddle in the

world. The diagram below is a cross-sectional view of the griddle. The griddle cooking surface

is the top of a chamber in which we have produced a unique environment. Welded stainless steel

reinforcement studs connect the chamber top to the chamber bottom. The perimeter joints are

all robotically welded to produce a vessel that is airtight, which is veried using a helium mass

spectrometer. The chamber is lled half full with distilled water. The remaining air is removed

and the chamber is welded shut. At this point, the chamber becomes a hermetically sealed vessel,

never to be opened again. The griddle steam chamber requires no water or maintenance. A

thermowell for a temperature sensor to sense temperature and a thermowell for the overtemp

safety shutdown system are also welded into the griddle steam chamber.

At temperatures below 212°F (100°C), the chamber is actually in a vacuum, similar to that of a

canning jar. At temperatures above 212°F (100°C), the chamber operates under pressure. Located

between the water and the bottom of the cooking surface is the best heat transfer medium –

steam, the most effective way to transfer heat. The temperature sensor senses the temperature

of the steam and reports this data to the thermostat, which energizes the heating elements. This

system maintains the griddle cooking surface temperatures to within ± 5°F (2.7°C) over the

entire cooking surface and provides a near instant temperature recovery, even in the same spot on

the griddle, when turning food in place.

Loading ...

Loading ...

Loading ...