Loading ...

Loading ...

Loading ...

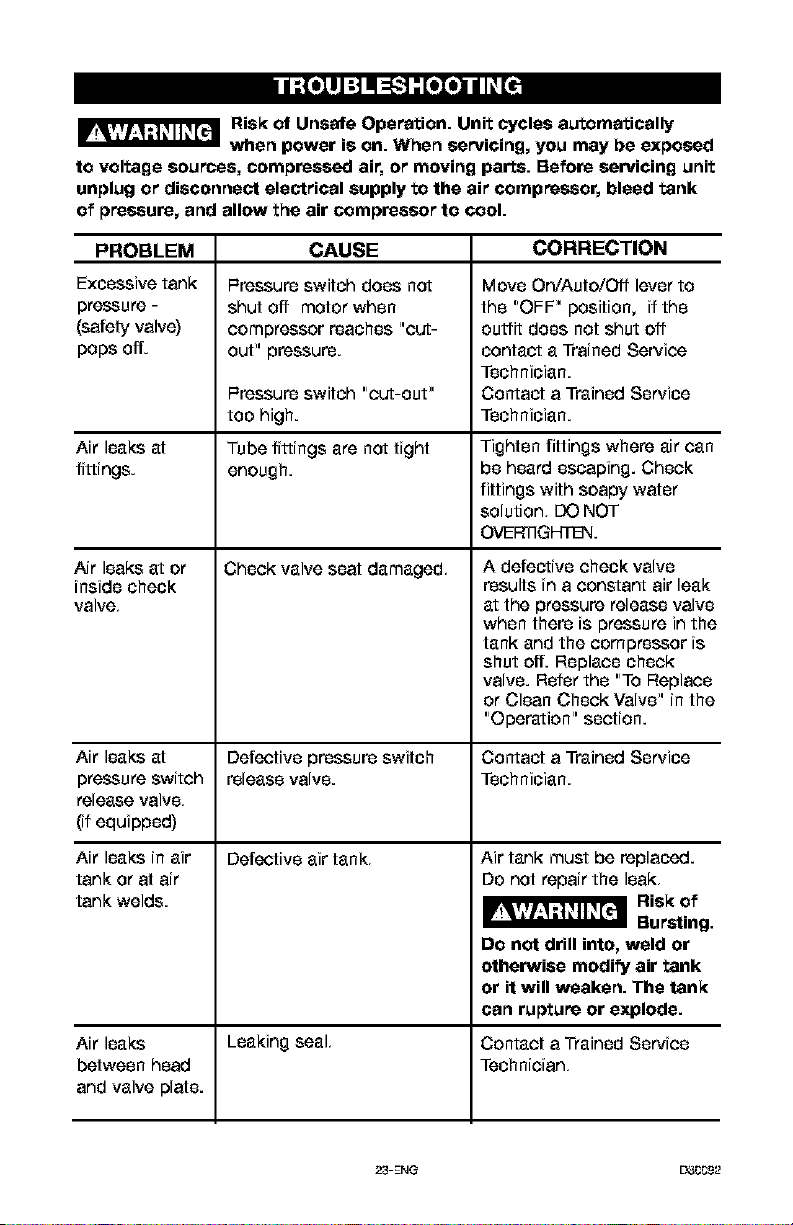

Risk of Unsafe Operation. Unit cycles automatically

when power is on. When servicing, you may be exposed

to voltage sources, compressed air, or moving parts. Before servicing unit

unplug or disconnect electrical supply to the air compressor, bleed tank

of pressure, and allow the air compressor to cool.

PROBLEM CAUSE CORRECTION

Excessive tank

pr_ure -

(safety valve)

peps off.

Air leaks at

fittings.

Air leaks at or

inside check

valve,

Pressure switch does not

shut off motor when

compressor reaches "out-

OUt_"pressure.

Pressure switch "cut-out"

too high.

Tube fittings are not tight

enough.

Check valve seat damaged,

Move On/Auto/Off lever to

the "OFF" position, if the

outfit does not shut off

contac_ a Trained Service

Technician.

Contact a Trained Service

Technician.

Tighten fittings where air can

be heard escaping. Check

fittings with soapy water

solution, DO NOT

OVER]IGHTE_.

A defective check valve

results in a constant air leak

at the pressure release valve

when there is pressure in the

tank and the compressor is

shut off. Replace check

valve. Refer the "To Replace

or Clean Check Valve" in the

"Operation" section.

Air leaks at Defective pressure switch Contact a Trained Service

pressure switch release valve. Technician.

release valve,

(if equipped)

Air leaks in air Defective air tank,

tank or at air

tank welds.

Air tank must be replaced.

Do not repair the leak,

Risk of

Bursting.

DO not drill into, weld or

otherwise modify air tank

or it will weaken. The tank

can rupture or explode.

Air leaks Leaking seal, Contact a Trained Service

between head Technician,

and valve plate.

23-EN_ EY30092

Loading ...

Loading ...

Loading ...