Loading ...

Loading ...

Loading ...

9

3.5 INSTALLING NON-INSULATED DUCTS AND DIFFUSERS (CONT’D)

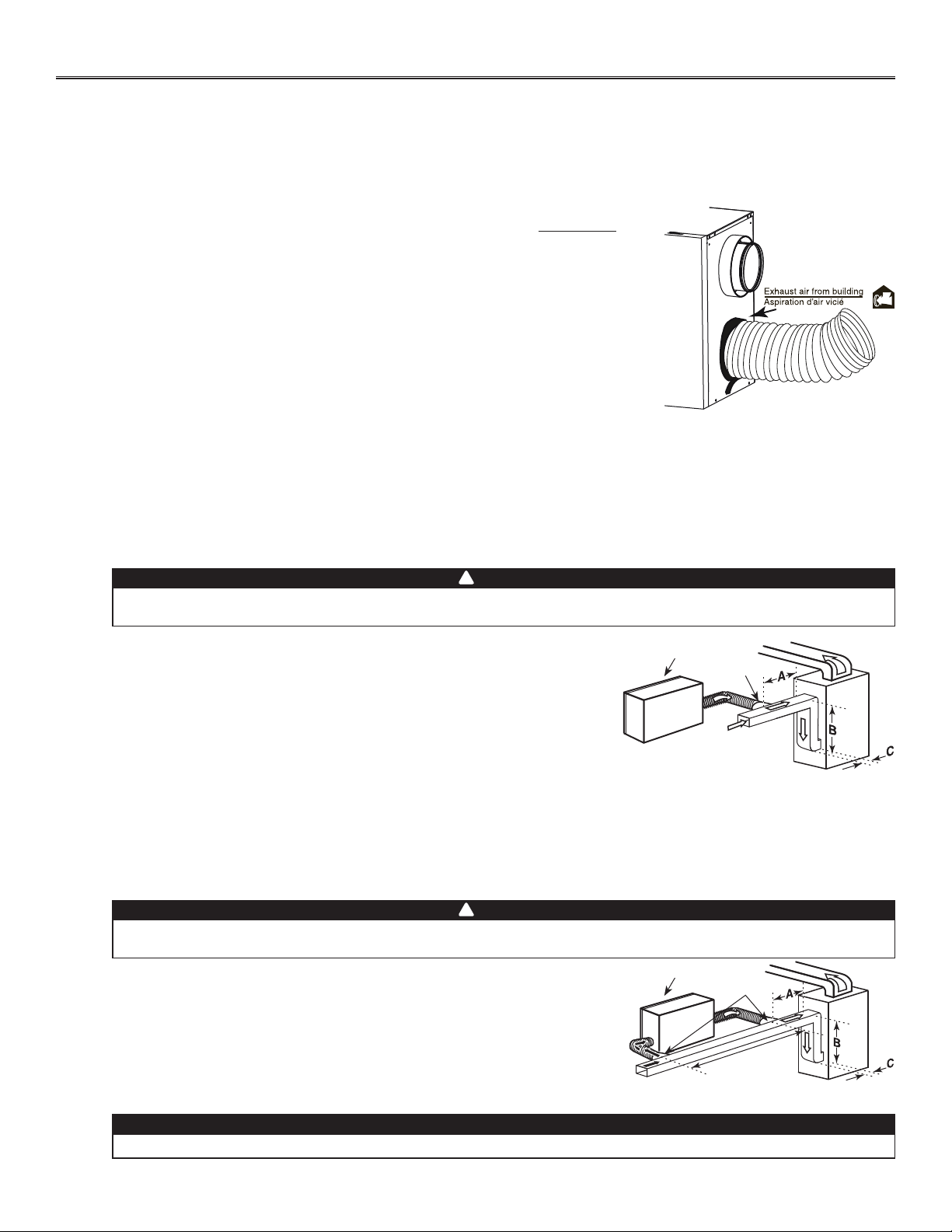

Stale air exhaust ductwork

Same as for Fully Ducted System, described in step 3.5.1.

3.5.2 CENTRAL DRAW POINT (AS ILLUSTRATED IN SECTION 1.2)

Fresh air distribution ductwork

When performing duct connections, always use approved tools and materials. Respect all corresponding

laws and safety regulations. Please refer to your local building code.

WARNING

!

• Locate the opening for fresh air ductwork on the forced air unit return duct

at a minimum linear distance of 9’ 10” (3 m) upstream (from forced air unit drop:

A+B+C). Cut out a 5” Ø hole in this location, using metal shear.

• Use a metal transition (not included, available in hardware store) to connect the

unit duct to the forced air unit return duct.

• Attach the other end of the flexible duct to the fresh air to building port (see

icon on the left side of the unit). Use tie wrap and duct tape to seal the connection.

See illustration at right.

3.5.1 FULLY DUCTED SYSTEM (AS ILLUSTRATED IN SECTION 1.1) (CONT’D)

HOW TO CONNECT THE FLEXIBLE DUCTS TO THE UNIT PORTS

Both flexible ducts attached to the diffusers must be connected to the bottom ports of

the unit. When facing the unit door, the fresh air to building port is located on left side

and the exhaust air from building port is on the right side. Refer to the identification

labels affixed beside each unit ports. Using tie wrap, attach the fresh air to building

duct to its corresponding port, then do the same for the exhaust air to building duct

and port. See illustration at right.

NOTE: Use an insulated duct (not included) if the duct will have to go through a

space where it is possible to experience extreme temperature conditions

(eg: in northern area, not unheated attic in winter or uncooled attic in southern

area). Also, if you plan to stop the unit for more than 12 hours, we recommend

to cover the duct with R12 insulation.

VJ0159

RIGHT SIDE OF THE UNIT

3. INSTALLATION (CONT’D)

VJ0099

A + B + C = NOT LESS

THAN 9’ 10” (3 M)

UNIT DOOR

METAL

TRANSITION

Fresh air distribution ductwork (return side connection)

Same as for Central Draw Point, described in step 3.5.2.

3.5.3 SIMPLIFIED INSTALLATION (AS ILLUSTRATED IN SECTION 1.3)

Stale air exhaust ductwork (return side connection)

When performing duct connections, always use approved tools and materials. Respect all corresponding

laws and safety regulations. Please refer to your local building code.

WARNING

!

• Locate the opening for stale air ductwork on the forced air unit return duct at

least 3’ (0.9 m) from fresh air ductwork connection. Cut out a 5” Ø hole in this

location, using metal shear.

• Use a metal transition (not included, available in hardware store) to connect the

unit duct to the forced air unit return duct.

• Attach the other end of the flexible duct to the exhaust air from building port (see

icon on the right side of the unit). Use tie wrap and duct tape to seal the connection.

See illustration at right.

The furnace blower must be running when the ventilation unit is in operation.

CAUTION

VJ0100

3’ (0.9 M)

MINIMUM

UNIT DOOR

A + B + C = NOT LESS

THAN 9’ 10” (3 M)

METAL

TRANSITIONS

Loading ...

Loading ...

Loading ...