Loading ...

Loading ...

Loading ...

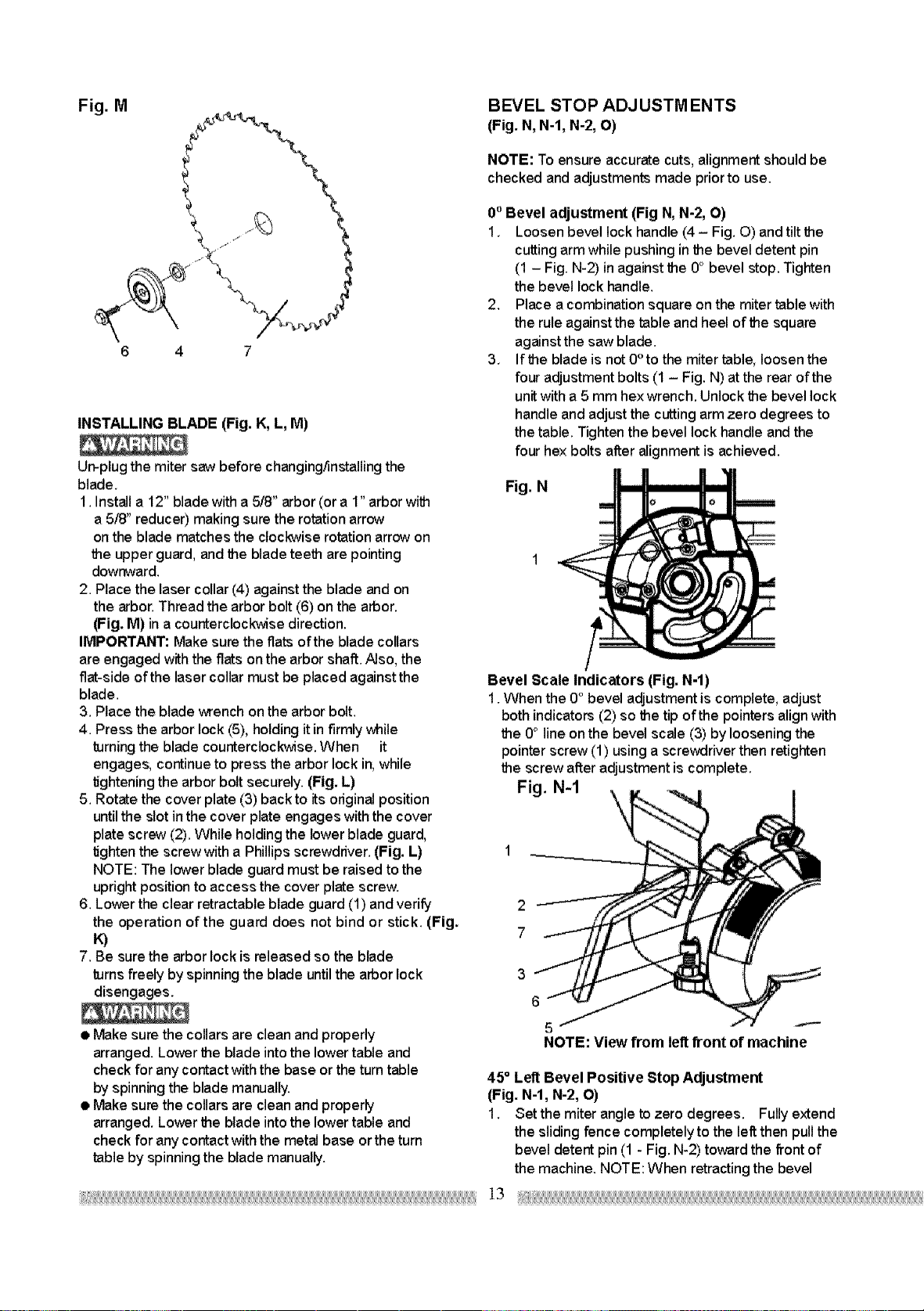

Fig. M BEVEL STOP ADJUSTM ENTS

(Fig. N, N-l, N-2, O)

NOTE: To ensure accurate cuts, alignment should be

checked and adjustments made prior to use.

6 4 7

INSTALLING BLADE (Fig. K, L, M)

Un-plug the miter saw before changing/installing the

blade,

1. Install a 12" blade with a 5f8" arbor (or a 1" arbor with

a 5/8" reducer) making sure the rotation arrow

on the blade matches the clockwise rotation arrow on

the upper guard, and the blade teeth are pointing

downward.

2. Place the laser collar (4) against the blade and on

the arbor. Thread the arbor bolt (6) on the arbor.

(Fig. M) in a counterclockwise direction.

IMPORTANT: Make sure the flats of the blade collars

are engaged with the fiats on the arbor shaft. Also, the

flat-side of the laser collar must be placed against the

blade.

3. Place the blade wrench on the arbor bolt.

4. Press the arbor lock (5t, holding it in firmly while

turning the blade counterclockwise. When it

engages, continue to press the arbor lock in, while

tightening the arbor bolt securely, (Fig. L)

5. Rotate the cover plate (3) backto its original position

until the slot in the cover plate engages with the cover

plate screw (21. While holding the lower blade guard,

tighten the screw with a Phillips screwdriver. (Fig. L)

NOTE: The lower blade guard must be raised to the

upright position to access the cover plate screw.

6. Lower the clear retractable blade guard (1) and verify

the operation of the guard does not bind or stick. (Fig.

K)

7. Be sure the arbor lock is released so the blade

turns freely by spinning the blade until the arbor lock

disengages,

0° Bevel adjustment (Fig N, N-2, O)

1, Loosen bevel lock handle (4- Fig. O) and tilt the

cutting arm while pushing inthe bevel detent pin

(1 - Fig. N-21 in against the 0° bevel stop. Tighten

the bevel lock handle.

2. Place a combination square on the miter table with

the rule against the table and heel of the square

against the saw blade.

3, If the blade is not 0° to the miter table, loosen the

four adjustment bolts (1 - Fig. N) at the rear of the

unitwith a 5 mm hex wrench. Unlock the bevel lock

handle and adjust the cutting arm zero degrees to

the table. Tighten the bevel lock handle and the

four he× bolts after alignment is achieved.

Fig. N

Bevel Scale Indicators (Fig. N-l)

1. When the 0° bevel adjustment is complete, adjust

both indicators (2) so the tip of the pointers align with

the 0° line onthe bevel scale (3) by loosening the

pointer screw (11 using a screwdriver then retighten

the screw after adjustment is complete.

Fig. N-1

2

7

3

6

• Make sure the collars are clean and properly

arranged. Lower the blade into the lower table and

check for any contact with the base or the turn table

by spinning the blade manually.

• Make sure the collars are clean and properly

arranged. Lover the blade into the lower table and

check for any contact with the metal base or the turn

table by spinning the blade manually.

5

NOTE: View from leftfront of machine

45 ° Left Bevel Positive Stop Adjustment

(Fig. N-l, N-2, O)

1. Set the miter angle to zero degrees. Fully extend

the sliding fence completely to the left then pull the

bevel detent pin (1 - Fig. N-2t toward the front of

the machine, NOTE: When retracting the bevel

Loading ...

Loading ...

Loading ...