Loading ...

Loading ...

Loading ...

Read these instructions completely

before you attempt to assemble or

operate your new equipment. Your

tiller has been assembled at the fac-

tory with the exception of those parts

left unassembled for shipping pur-

poses. Steps in this section show

you how to do so. To ensure safe

and proper operation of your ma-

chine, all parts and hardware you in-

stall or adjust must be tightened se-

curely. Use the correct tools as nec-

essary to ensure proper tightness.

UNPACKINGINSTRUCTIONS

• Inspect your machine immediately.

Be sure neither the carton nor con-

tents have been damaged. If you

find or have reason to suspect

damage, contact the nearest

Sears Service Center/Department

for assistance.

• Once the cardboard shipping car-

ton is open, remove any packing

material from around the machine.

Remove any staples securing bot-

tom of carton to wood pallet. Lift

off carton. Before disposing of the

carton or any of the packing mate-

rials, be sure to check them thor-

oughly for any small parts.

• Leave unit on base of pallet dur-

.ing assembly steps (to safely re-

move unit from pallet, wait until

you have installed the handlebar

assembly).

• Also remove any packaging around

the handlebar.

• Perform the assembly on a clean,

level surface. If you need to move

the machine, be careful not to

severely bend any of the control

cables on the equipment.

Tools Needed For Assembly:

• Open,end or adjustable wrenches:

One 3/8";Two 7/16";

One 1/2"; Two9/16"

• Funnel (toadd motor oil)

• Rag (forany oil cleanup needed)

• Block of Wood (to support Me tiller

when removing wheel)

• Ruler (for belttension check)

ASSEMBLY

H

G

B

D

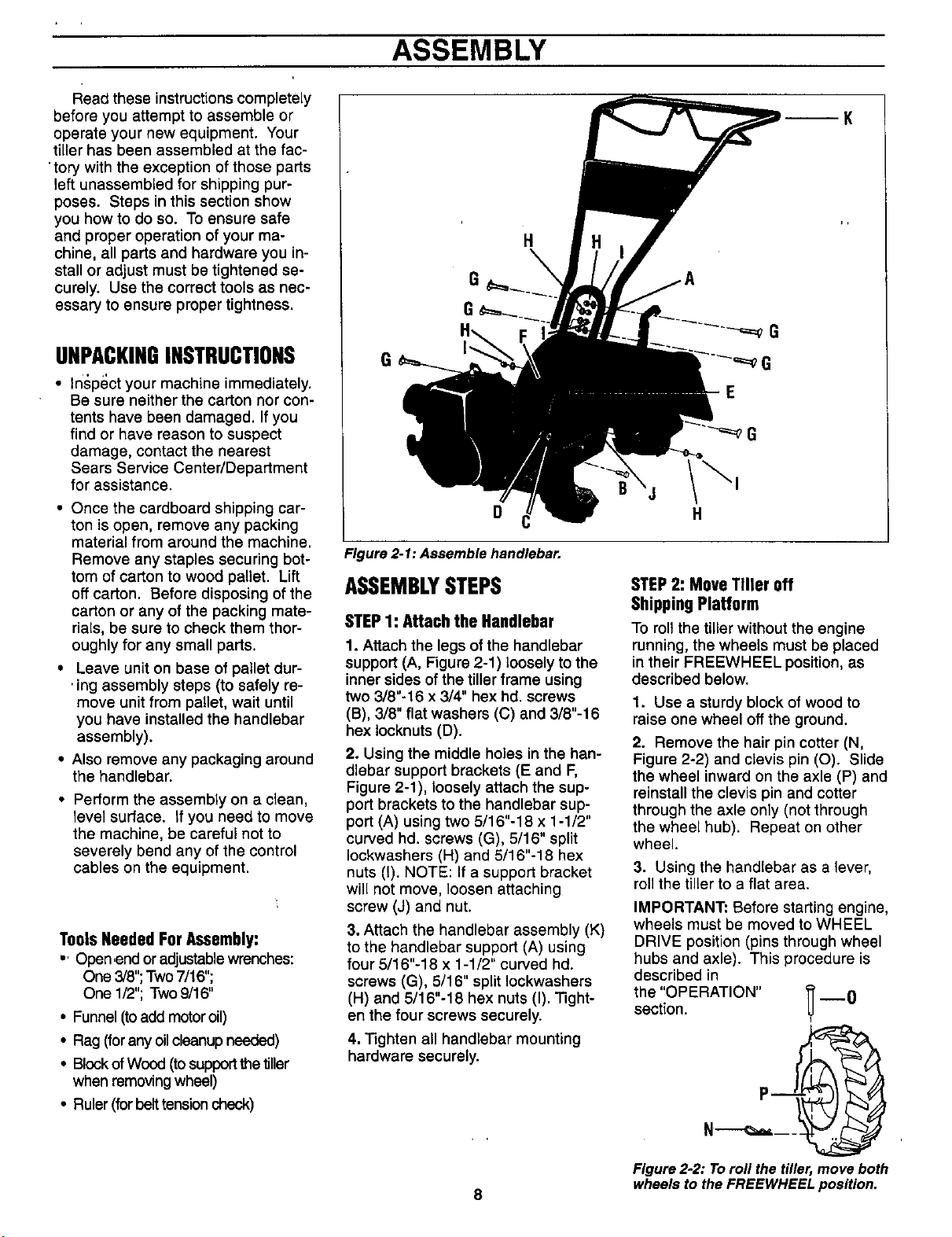

Figure 2-1: Assemble handlebar.

ASSEMBLYSTEPS

STEP1: Attach the Handlebar

1. Attach the legs of the handlebar

support (A, Figure 2-1) loosely to the

inner sides of the tiller frame using

two 3/8"-16 x 3/4" hex hd. screws

(B), 3/8" flat washers (C) and 3/8"-16

hex Iocknuts (D).

2. Using the middle holes in the han-

dlebar support brackets (E and F,

Figure 2-1), loosely attach the sup-

port brackets to the handlebar sup-

port (A) using two 5/16"-18 x 1-1/2"

curved hd. screws (G), 5/16" split

Iockwashers (H) and 5/16"-18 hex

nuts (I). NOTE: If a support bracket

will not move, loosen attaching

screw (J) and nut.

3. Attach the handlebar assembly (K)

to the handlebar support (A) using

four 5/16"-18 x 1-1/2" curved hd.

screws (G), 5/16" split Iockwashers

(H) and 5/16"-18 hex nuts (I). Tight-

en the four screws securely.

4. Tighten all handlebar mounting

hardware securely.

8

STEP2: MoveTiller off

ShippingPlatform

To roll the tiller without the engine

running, the wheels must be placed

in their FREEWHEEL position, as

described below.

1. Use a sturdy block of wood to

raise one wheel off the ground.

2. Remove the hair pin cotter (N,

Figure 2-2) and clevis pin (O). Slide

the wheel inward on the axle (P) and

reinstall the clevis pin and cotter

through the axle only (not through

the wheel hub). Repeat on other

wheel.

3. Using the handlebar as a lever,

roll the tiller to a flat area.

IMPORTANT: Before starting engine,

wheels must be moved to WHEEL

DRIVE position (pins through wheel

hubs and axle). This procedure is

described in

the "OPERATION" _ --0

section.

U

I

N ,

Figure22: Toroll the tiller,move both

wheels to theFREEWHEEL position.

Loading ...

Loading ...

Loading ...