Loading ...

Loading ...

Loading ...

CUSTOMER RESPONSIBILITIES

REQUIREDMAINTENANCESCHEDULE

Before Every Every Every As

REQUIREDMAINTENANCE Each 10 30 50 Noted

Use Hours Hours Hours

Tiller Lubrication

CheckEngine0il Level"EngineLubrication" • 1

ChangingEngine0il • 2

CheckingTransmissionGear0il Level • 4

Air cleaner Maintenance • 5

EngineCooling System Maintenance

Spark Plug Maintenance

TightenTillerHardware • 3

CheckTinesfor Wear •

Checking/Adjusting BeltTension • 3

CheckAnti-Reverse Stake

NOTEt - Checkfrequentlyduringfirst 2 hoursofnewoperation;thereafterevery5hours.

NOTE2- Changeafter2initialoperatinghours;thereafterevery10hours.

NOTE3- Checkafter2 initialoperatinghours;thereafterevery10hours.

NOTE4 - Checkafter2 initialoperatinghours;thereafterevery30hours.

NOTE5 - Replacemoreoftenif usedinextremelydustyor dirtyconditions

GENERALRECOMMENDATIONS Tiller Lubrication

The Warranty on this machine does

not cover items that have been sub-

jected to operator abuse or negli-

gence. To receive full value from the

warranty, the operator must maintain

the machine as instructed inthismanual.

Some adjustments will need to be

made periodically to properly main-

tain your machine.

Keep the air filters clean and change

the spark plug annually. A clean air

filter system and new spark plug help

the engine run better and last longer.

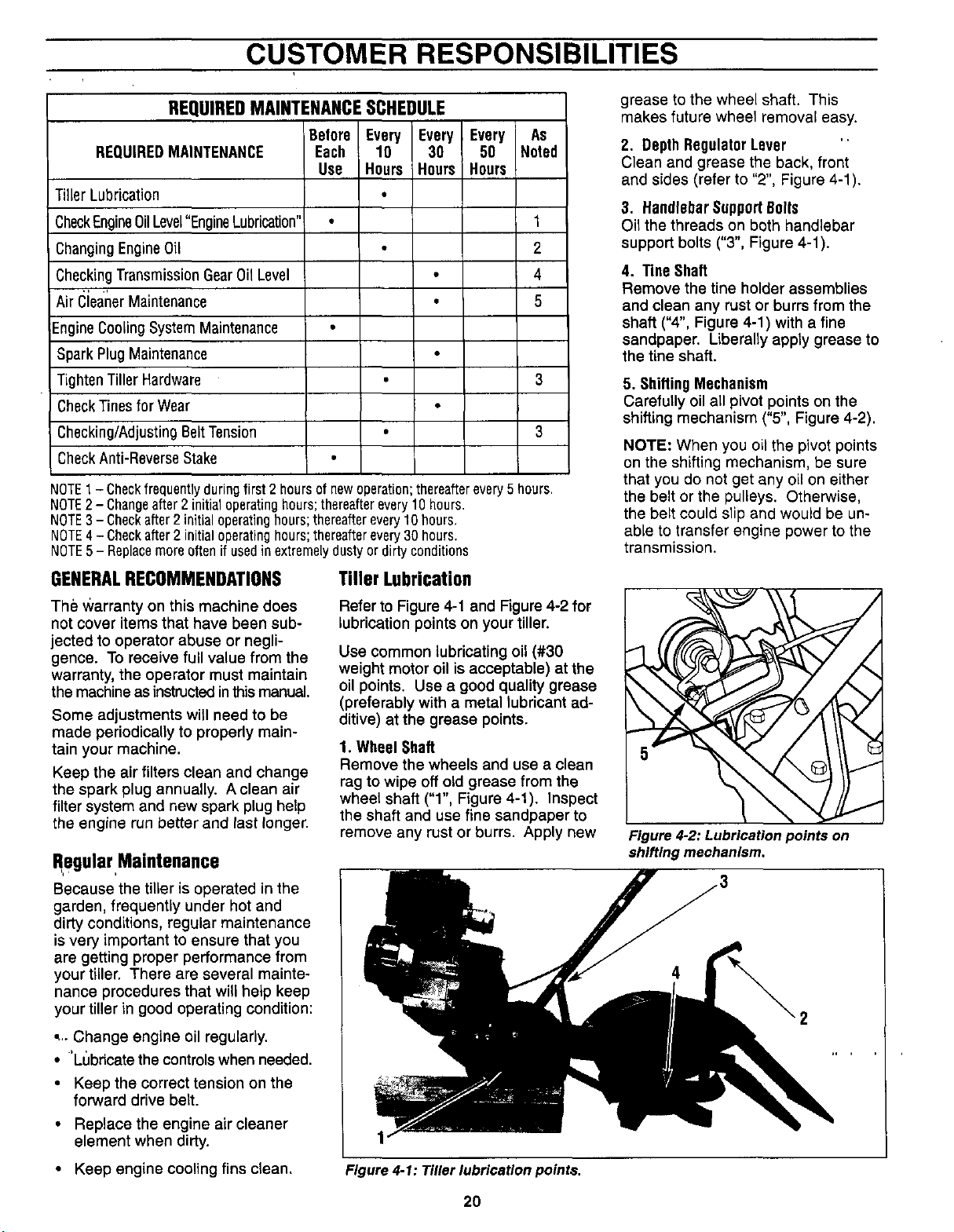

Refer to Figure 4-1 and Figure 4-2 for

lubrication points on your tiller.

Use common lubricating oil (#30

weight motor oil is acceptable) at the

oil points. Use a good quality grease

(preferably with a metal lubricant ad-

ditive) at the grease points.

1. Wheel Shaft

Remove the wheels and use a clean

rag to wipe off old grease from the

wheel shaft ("1", Figure 4-1). Inspect

the shaft and use fine sandpaper to

remove any rust or burrs. Apply new

Regular,Maintenance

Because the tiller is operated in the

garden, frequently under hot and

dirty conditions, regular maintenance

is very important to ensure that you

are getting proper performance from

your tiller. There are several mainte-

nance procedures that will hetp keep

your tiller in good operating condition:

• ,. Change engine oil regularly.

• 'Lubricate the controls when needed.

• Keep the correct tension on the

forward drive belt.

• Replace the engine air cleaner

element when dirty.

• Keep engine cooling fins clean. Figure 4-1: Tiller lubricaUon points.

grease to the wheel shaft. This

makes future wheel removal easy.

2. DepthRegulatorLever "

Clean and grease the back, front

and sides (refer to "2", Figure 4-1 ).

3. HandlebarSupportBolls

Oil the threads on both handlebar

support bolts ("3", Figure 4-1).

4. Tine Shaft

Remove the tine holder assemblies

and clean any rust or burrs from the

shaft ("4", Figure 4-1) with a fine

sandpaper. Liberally apply grease to

the tine shaft.

5. ShiftingMechanism

Carefully oil all pivot points on the

shifting mechanism ("5", Figure 4-2),

NOTE: When you oil the pivot points

on the shifting mechanism, be sure

that you do not get any oil on either

the belt or the pulleys. Otherwise,

the belt could slip and would be un-

able to transfer engine power to the

transmission.

Figure 4-2: Lubrication points on

shifting mechanism,

2

2O

Loading ...

Loading ...

Loading ...