Loading ...

Loading ...

Loading ...

64 installation

Underbench oven

Your underbench oven looks best when the control panel

is directly under the benchtop. An upper infill panel may

be added if the cooktop placed above the benchtop is too

deep. Refer to cooktop installation instructions for required

clearance between cooktop and oven.

IMPORTANT!

Note: Dimension’D’*

A requirement for all EVEPxxxx pyrolytic clean ovens and

Duo ovens – for proper ventilation there must be a gap

at the bottom rear of the cabinet. This can be a full width

opening 20mm deep.

Power point connection for the EVEP615SB and

EVEP618BB must be accessible with the appliance fully

installed. If the supply cord is damaged it must be replaced

by the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

Cut-out dimensions

type of fit A (width) B (height) C (depth)

Flush fit (mm)

600 600 581 min.

Proud fit (mm) 568 590 560 min.

Double oven Cut-out dimensions

type of fit A (width) B (height) C (depth)

Flush fit (mm)

600 1086 581 min.

Proud fit (mm) 568 1078 560 min.

INSTALLATION OF THE APPLIANCE

Pyrolytic underbench cut-out dimensions

type of fit A (width) B (height) C (depth) D*

Flush fit (mm)

600 600 581 min. 20

Duo oven cut-out dimensions

type of fit A (width) B (height) C (depth) D*

Flush fit (mm)

600 893 581 min. 20

596mm

561mm

561mm

561mm

mounting

holes 582mm

mounting holes

582mm

fit long screws

provided

mounting holes

fit countersunk screws

with plastic spacers

provided

mounting

holes 582mm

596mm

650mm

min.

Plastic clips

Plastic clip

securing points

installation 65

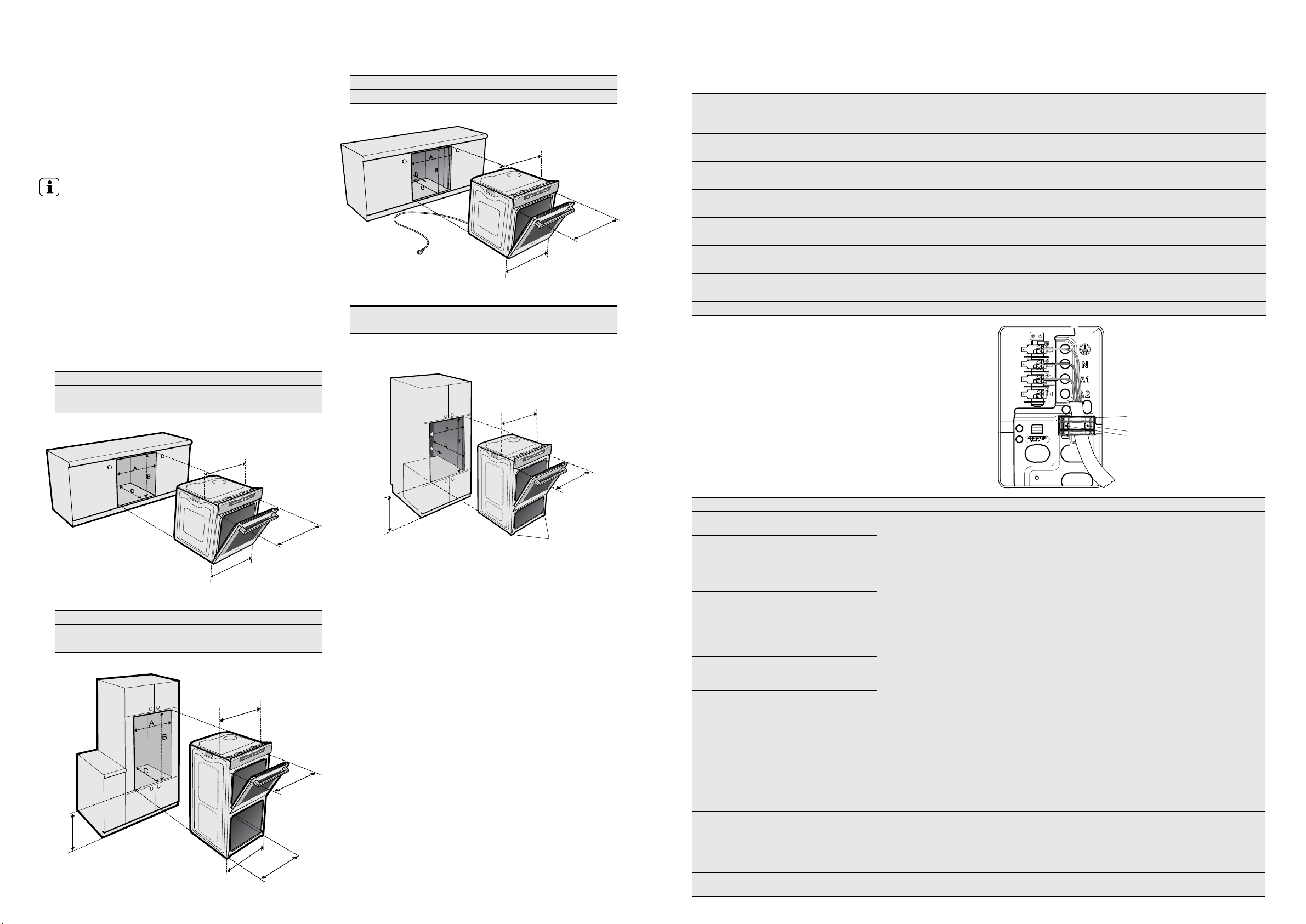

Hard wiring details

1. Remove terminal cover plate from rear panel of

appliance.

2. Fit wires through hole in cover plate and make

connections to terminals.

3. Engage wires into plastic clip. Secure plastic clip with

two long silver screws (supplied in separate bag).

4. Replace cover plate onto rear panel.

Error codes

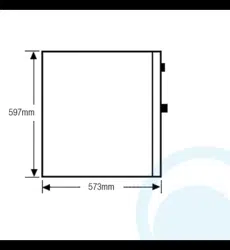

TECHNICAL SPECIFICATIONS

model

product dimensions

(h x w x d) mm

electrical

connection

min. fuse rating max. power rating max. current rating

EVE611SA 597 x 596 x 573 230-240V/50Hz 16A 3.1kW 12.9A

EVE613SA 597 x 596 x 573 230-240V/50Hz 16A 3.1kW 12.9A

EVE614BA 597 x 596 x 573 230-240V/50Hz 16A 3.1kW 12.9A

EVE616BA 597 x 596 x 573 230-240V/50Hz 16A 3.1kW 12.9A

EVEP611SB 597 x 596 x 573 230-240V/50Hz 16A 3.1kW 12.9A

EVEP614BB 597 x 596 x 573 230-240V/50Hz 16A 3.1kW 12.9A

EVEP613SB 597 x 596 x 573 230-240V/50Hz 16A 3.1kW 12.9A

EVEP616BB 597 x 596 x 573 230-240V/50Hz 16A 3.1kW 12.9A

EVEP615SB 597 x 596 x 573 230-240V/50Hz 16A 3.5kW 12.9A

EVEP618BB 597 x 596 x 573 230-240V/50Hz 16A 3.5kW 12.9A

EVE623SA 890 x 596 x 573 230-240V/50Hz 25A 5.3kW 22.1A

EVEP623SB 890 x 596 x 573 230-240V/50Hz

25A 5.3kW 22.1A

EVEP626BB 890 x 596 x 573 230-240V/50Hz

25A 5.3kW 22.1A

EVE633SA 1083 x 596 x 573 230-240V/50Hz

25A 6.2kW 24.2A

error code description comment fix

F01 or 01 Door lock sensor alarm

This relates to a door lock failure which is only

associated with the Pyrolytic product

Check wiring/plugs or replace door lock

F02 or 02 Door lock actuator alarm

F04 or 04 Oven Probe (PT500) out

This relates to the temperature sensing probe

which may be out of tolerance, of range alarm

or have open/short circuit connections

Replace probe

F05 or 05

Oven Probe (PT500) too

high temperature alarm

25

Board Temperature

Sensor (NTC) too high

temperature alarm

This relates to the temperature of the

powerboard and/or the (NTC)

on the powerboard

Cooling fan not working or replace

powerboard

26

Board Temperature

Sensor (NTC) out of

range warning

6

Board Temperature

Sensor (NTC) out of

range alarm

F08 or 08 Communication alarm

This relates to an error in communication

between the powerboard and the IOI

controller. This can occur if the IOI controller is

connected while the powerboard is energised

Reset power. (Minimum of 20 sec.) or

check or replace data cable

F09 or 09

Software compatibility

code alarm

This relates to a mismatch between

powerboard firmware version and the IOI

controller firmware version. Most likely caused

by an un-programmed powerboard

Replace Powerboard

C1 Telescopic runners fitted Only applies to Pyrolytic product

Remove both side racks and re-start

pyrolytic cycle

C3 Door open Only applies to Pyrolytic product Close door and restart pyrolytic cycle

F03 or 03

EEPROM check sum

alarm

Relates to the controller Replace Controller

F14 or 14

EEPROM compatibility

code alarm

Relates to the controller Replace Controller

D

561mm

650mm

min.

596mm

mounting

holes 582mm

mounting

holes 582mm

Loading ...

Loading ...