Loading ...

Loading ...

Loading ...

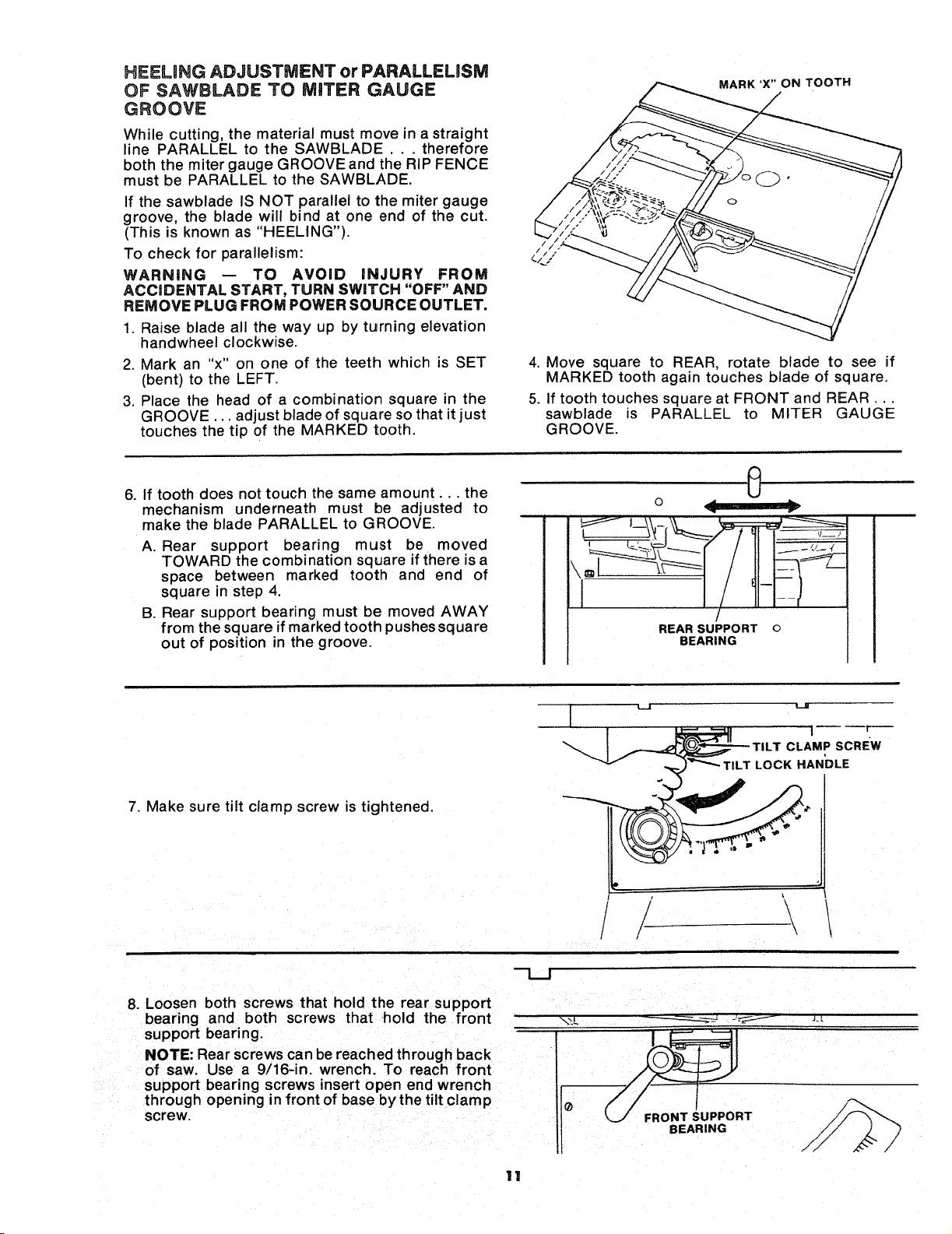

HEELING ADJUSTMENT or PARALLELISM

OF SAWBLADE TO MITER GAUGE

GROOVE

While cutting, the material must move in a straight

line PARALLEL to the SAWBLADE . . . therefore

both the miter gauge GROOVE and the RIP FENCE

must be PARALLEL to the SAWBLADE.

If the sawblade IS NOT parallel to the miter gauge

groove, the blade will bind at one end of the cut.

(This is known as "HEELING").

To check for parallelism:

WARNING -- TO AVOID INJURY FROM

ACCIDENTAL START, TURN SWITCH "OFF" AND

REMOVE PLUG FROM POWER SOURCE OUTLET.

1. Raise blade all the way up by turning elevation

handwheel clockwise.

2. Mark an "x" on one of the teeth which is SET

(bent) to the LEFT.

3. Place the head of a combination square in the

GROOVE... adjust blade of square so that it just

touches the tip of the MARKED tooth.

MARK'X"ON TOOTH

//

//

4. Move square to REAR, rotate blade to see if

MARKED tooth again touches blade of square.

5. If tooth touches square at FRONT and REAR...

sawblade is PARALLEL to MITER GAUGE

GROOVE.

6. If tooth does not touch the same amount .. the

mechanism underneath must be adjusted to

make the blade PARALLEL to GROOVE.

A. Rear support bearing must be moved

TOWARD the combination square if there is a

space between marked tooth and end of

square in step 4.

B. Rear support bearing must be moved AWAY

from the square if marked tooth pushes square

out of position in the groove.

o

I

REAR SUPPORT o

BEARING

t_J

I r---

tiLT CLAMP SCREW

ILT LOCK HANDLE

7. Make sure tilt clamp screw is tightened.

/

! \

/- \

8. Loosen both screws that hold the rear support

bearing and both screws that-hold the front

support bearing.

NOTE: Rear screws can be reached through back

of saw. Use a 9/16-in. wrench. To reach front

support bearing screws insert open end wrench

through opening in front of base bythe tilt clamp

screw.

-'l.J

"%'-.L

O

FRONT SUPPORT

BEARING

11

Loading ...

Loading ...

Loading ...