Loading ...

Loading ...

Loading ...

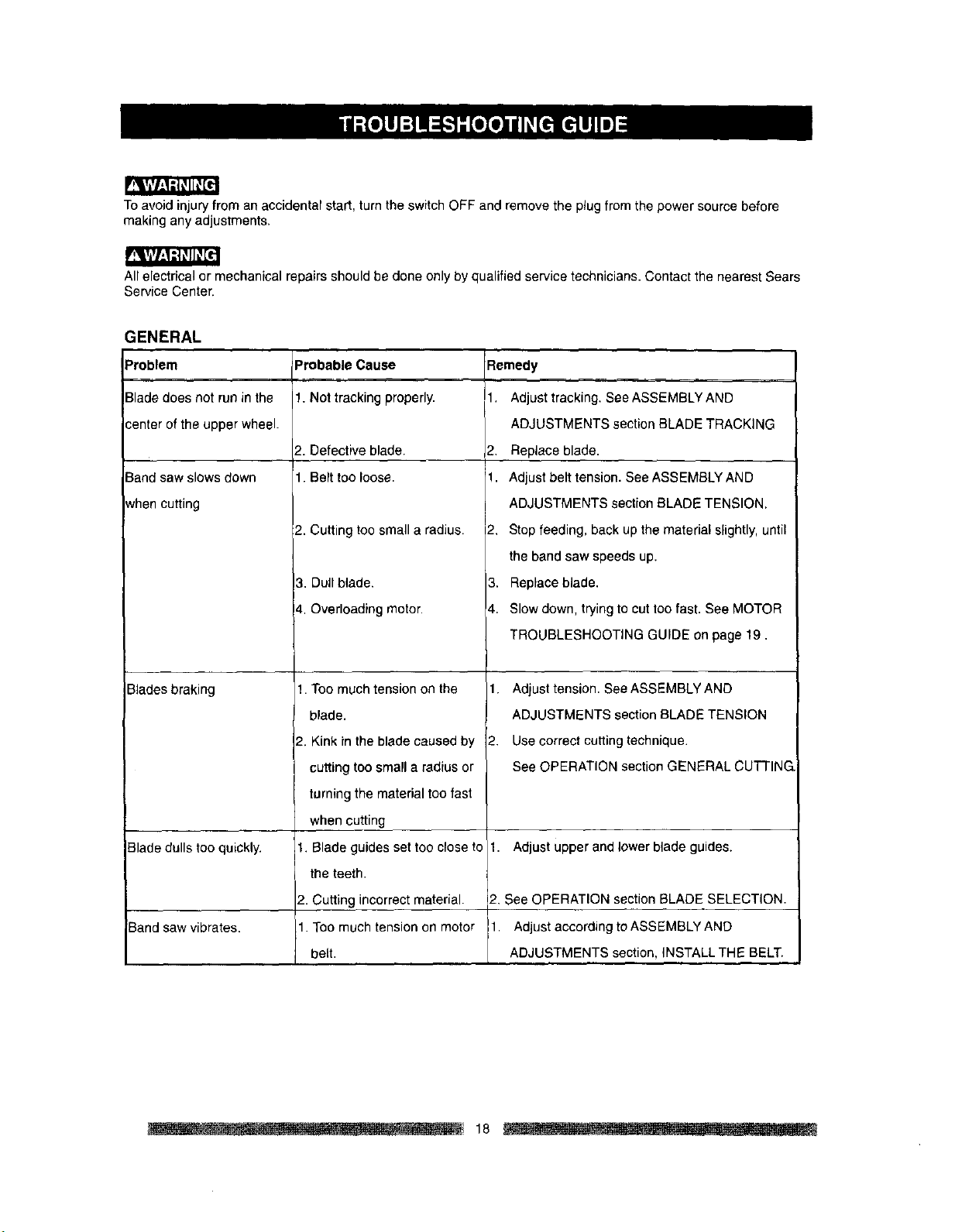

To avoid injuryfrom an accidental start, turn the switch OFF and remove the ptug from the power source before

making any adjustments.

All electrical or mechanical repairs should be done only by qualified service technicians. Contact the nearest Sears

Service Center.

GENERAL

Problem

Blade does not run in the

center of the upper wheel.

Band saw slows down

when cutting

Blades braking

Blade dulls too quickly.

Band saw vibrates.

Probable Cause

1. Not tracking properly.

2. Defective blade, 2.

1. Belt too loose. 1.

2. Cutting too small a radius. 2.

3. Dull blade. 3.

4. Overloading motor. 4.

Remedy

1. Adjust tracking. See ASSEMBLY AND

ADJUSTMENTS section BLADE TRACKING

Replace blade.

Adjust belt tension. See ASSEMBLY AND

ADJUSTMENTS section BLADE TENSION.

Stop feeding, back up the material slightly, until

the band saw speeds up.

Replace blade.

Slow down. trying to cut too fast. See MOTOR

TROUBLESHOOTING GUIDE on page 19.

!. Too much tension on the 1.

blade.

2. Kink in the blade caused by 2.

cutting too small a radius or

turning the material too fast

when cutting

t. Blade guides set too close to I.

the teeth.

2. Cutting incorrect material.

1. Too much tension on motor

belt.

Adjust tension. See ASSEMBLY AND

ADJUSTMENTS section BLADE TENSION

Use correct cutting technique.

See OPERATION section GENERAL CUTTING,

Adjust upper and lower blade guides.

2. See OPERATION section BLADE SELECTION.

1. Adjust according to ASSEMBLY AND

ADJUSTMENTS section, INSTALL THE BELT.

18

Loading ...

Loading ...

Loading ...