Loading ...

Loading ...

Loading ...

EXTENSION CORDS

The use of any extension cord will cause some drop in

voltage and loss of power.

• Wires of the extension cord must be of sufficientsize to

carry the current and maintain adequate voltage.

• Use the table to determine the minimum wire size (A.W.G.)

extension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the too_plug.

• If the extension cord is worn, cut, or damaged in any way,

replace it immediately.

Extension Cord Length

Wire Size A.W.G.

Up to 25 ft........................................ 18

NOTE: Using extension cords over 25 ft. long is not

recommended.

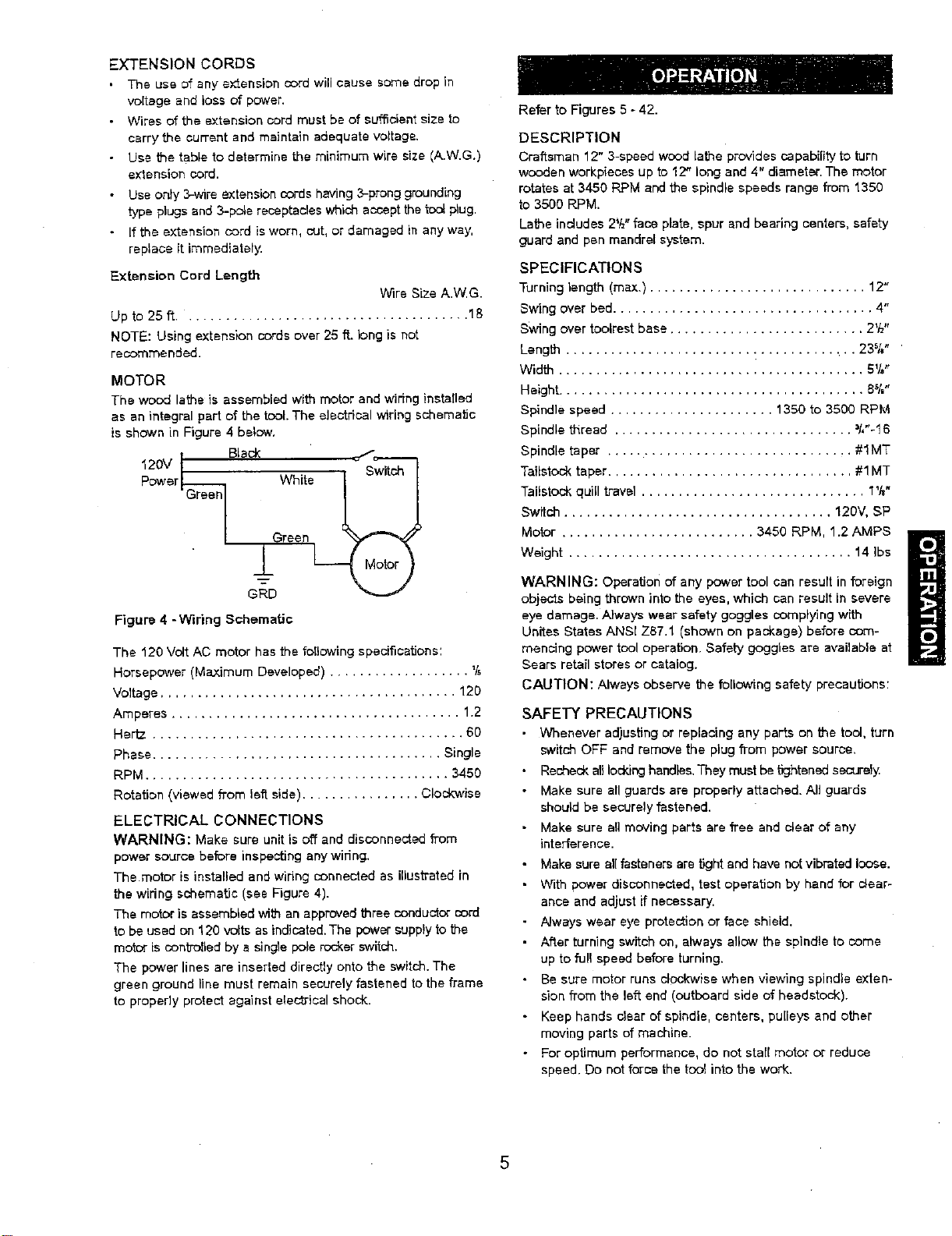

MOTOR

The wood lathe is assembled with motor and wiring installed

as an integral part of the tool. The electrical wiring schematic

is shown in Figure 4 below.

Black "

1/O:rl Whita _=-S_

_j_Green

GRD

Figure 4 -Wiring Schematic

The 120 Vo!t AC motor has the following specifications:

Horsepower (Maximum Developed) ................... 't_

Voltage ........................................ 120

Amperes ....................................... 1.2

Hertz .......................................... 60

Phase ....................................... Single

RPM ......................................... 3450

Rotation (viewed from left side) ................ Clockwise

ELECTRICAL CONNECTIONS

WARNING: Make sure unit is off and disconnected from

power source before inspecting any wiring.

The motor is installed and wiring connected as illustrated in

the wiring schematic (see Figure 4).

The motor is assembled with an approved three conductor cord

to be used on 120 volts as indicated. The power supp)y to the

motor is controlled by a slngle pole rocker switch.

The power lines are inserted directly onto the switch. The

green ground line must remain securely fastened to the frame

to properly protect against electrical shock.

Refer to Figures 5 - 42.

DESCRIPTION

Craftsman 12" 3-speed wood lathe provides capability to turn

wooden workpieces up to 12" long and 4" diameter. The motor

rotates at 3450 RPM and the spindle speeds range from 1350

to 3500 RPM.

Lathe includes 2'/="face plate, spur and bearing centers, safety

guard and pen mandrel system.

SPECIFICATIONS

Turning length (max.) ............................. 12"

Swing over bed ................................... 4"

Swing over toolrest base .......................... 2't7"

Length ....................................... 235t_,"'

Width ......................................... 5%"

Height......................................... 8';t,"

Spindle speed ...................... 1350 to 3500 RPM

Spindle thread ................................ _1,"-'16

Spindle taper ................................. #1MT

Tailstock taper ................................. #1 MT

Tailstock quill travel .............................. 1'/_"

Switch .................................... 120V, SP

Motor .......................... 3450 RPM, 1.2 AMPS

Weight ...................................... 14 ]bs

m

WARNING: Operation of any power tool can result in foreign

objects being thrown into the eyes, which can result in severe

eye damage. Always wear safety goggles complying with

Unites States ANSi Z87.1 (shown on package) before com-

mencing power tool operation. Safety goggles are available at

Sears retail stores or catalog.

CAUTION: Always observe the following safety precautions:

SAFETY PRECAUTIONS

• Whenever adjusting or replacing any parts on the tool, turn

switch OFF and remove the plug from power source.

Recheck allIod{ing handles.They must be tightened securely

• Make sure all guards are properly attached. All guards

should be securely _stened.

- Make sure all moving parts are free and clear of any

interference.

• Make sure allfasteners aretight and have not vibrated loose.

• With power disconnected, test operation by hand for clear-

ance and adjust if necessary.

• Always wear eye protection or face shield.

• After turning switch on, always allow the spindle to come

up to full speed before turning.

• Be sure motor runs clockwise when viewing spindle exten-

sion from the left end (outboard side of headstock).

• Keep hands clear of spindle, centers, pulleys and other

moving parts of machine.

• For optimum performance, do not stall motor or reduce

speed. Do not force the tool into the work.

5

Loading ...

Loading ...

Loading ...