Loading ...

Loading ...

Loading ...

[] Graspthesawhandlefirmlythensqueezetheswitch

trigger.Allowseveralsecondsforthebladeto reach

maximumspeed.

[] Slowlylowerthebladeintoandthroughtheworkpiece.

[] Releasetheswitchtriggerandallowthebladeto stop

rotatingbeforeraisingthebladeoutoftheworkpiece.

Waituntiltheelectricbrakestopsbladefromturning

beforeremovingtheworkpiecefromthe mitertable.

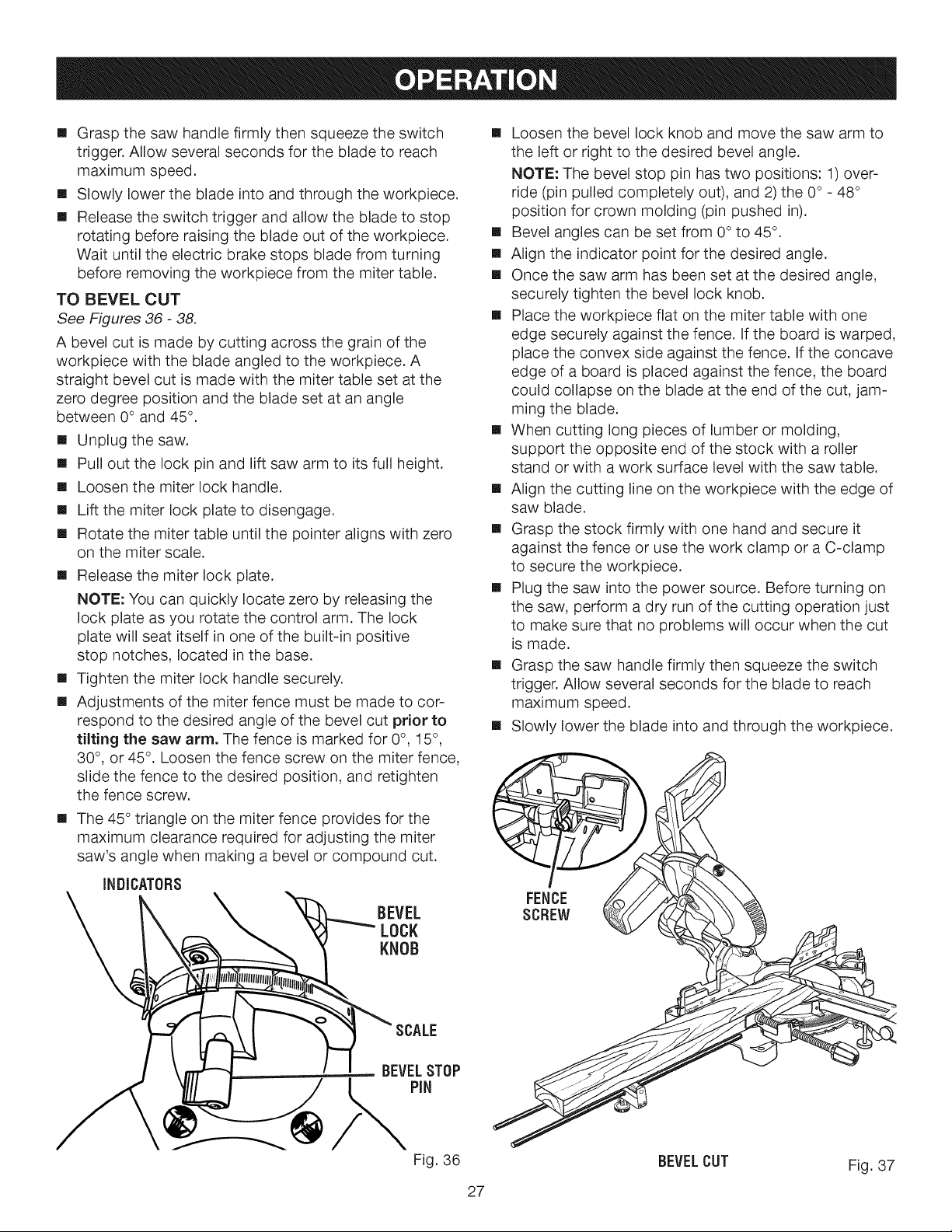

TO BEVEL CUT

See Figures 36 - 38.

A bevel cut is made by cutting across the grain of the

workpiece with the blade angled to the workpiece. A

straight bevel cut is made with the miter table set at the

zero degree position and the blade set at an angle

between 0° and 45°.

[] Unplug the saw.

[] Pull out the lock pin and lift saw arm to its full height.

[] Loosen the miter lock handle.

[] Lift the miter lock plate to disengage.

[] Rotate the miter table until the pointer aligns with zero

on the miter scale.

[] Release the miter lock plate.

NOTE: You can quickly locate zero by releasing the

lock plate as you rotate the control arm. The lock

plate will seat itself in one of the built-in positive

stop notches, located in the base.

[] Tighten the miter lock handle securely.

[] Adjustments of the miter fence must be made to cor-

respond to the desired angle of the bevel cut prior to

tilting the saw arm. The fence is marked for 0°, 15°,

30 °, or 45° . Loosen the fence screw on the miter fence,

slide the fence to the desired position, and retighten

the fence screw.

[] The 45° triangle on the miter fence provides for the

maximum clearance required for adjusting the miter

saw's angle when making a bevel or compound cut.

INDICATORS

BEVEL

LOCK

KNOB

BEVELSTOP

PiN

[] Loosen the bevel lock knob and move the saw arm to

the left or right to the desired bevel angle.

NOTE: The bevel stop pin has two positions: 1) over-

ride (pin pulled completely out), and 2) the 0 ° - 48 °

position for crown molding (pin pushed in).

[] Bevel angles can be set from 0° to 45°.

[] Align the indicator point for the desired angle.

[] Once the saw arm has been set at the desired angle,

securely tighten the bevel lock knob.

[] Place the workpiece flat on the miter table with one

edge securely against the fence. If the board is warped,

place the convex side against the fence. If the concave

edge of a board is placed against the fence, the board

could collapse on the blade at the end of the cut, jam-

ming the blade.

[] When cutting long pieces of lumber or molding,

support the opposite end of the stock with a roller

stand or with a work surface level with the saw table.

[] Align the cutting line on the workpiece with the edge of

saw blade.

[] Grasp the stock firmly with one hand and secure it

against the fence or use the work clamp or a C-clamp

to secure the workpiece.

[] Plug the saw into the power source. Before turning on

the saw, perform a dry run of the cutting operation just

to make sure that no problems will occur when the cut

is made.

[] Grasp the saw handle firmly then squeeze the switch

trigger. Allow several seconds for the blade to reach

maximum speed.

[] Slowly lower the blade into and through the workpiece.

FENCE

SCREW

Fig. 36

27

BEVELCUT

Fig. 37

Loading ...

Loading ...

Loading ...