Loading ...

Loading ...

Loading ...

Page 19 of 53

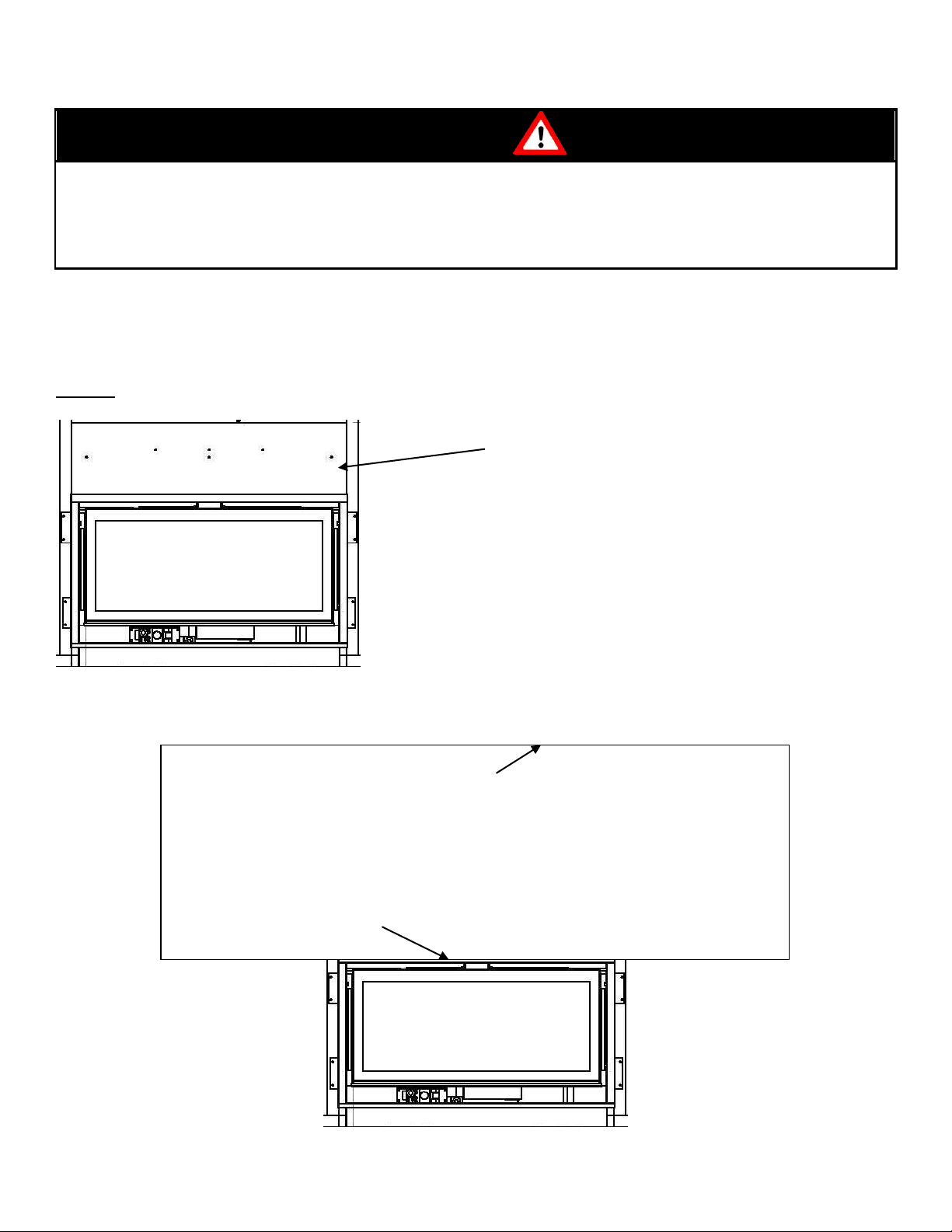

3.3.1 INSTALLING NON-COMBUSTIBLE BOARD

NOTE: To minimize joints, it may be best to replace the supplied non-combustible board with a larger piece.

WARNING

THE SURFACE ABOVE THE APPLIANCE GETS VERY HOT. IF PROPER FINISHING MATERIALS

ARE NOT USED, CRACKING CAN OCCUR.

LA SURFACE AU-DESSUS DE L'APPAREIL EST TRÈS CHAUDE. SI DES MATERIAUX DE

FINITION CORRESPONDANTS NE SONT PAS UTILISES, DES RISQUES PEUVENT

SURVENIR.

The 9.5” (241.3mm) above the appliance must not be finished with any combustible materials. If only a

painted surface is desired, a full single sheet of cement board should be used.

The manufacturer supplies only the minimum sized board required.

SUPPLIED NON-COMBUSTIBLE

BOARD 9.5” (241.3mm) HIGH x 36”

(914.4mm) WIDE

TO CEILING

RECOMMENDED REPLACEMENT CEMENT BOARD IF

INSTALLING WITH PAINTED SURFACE ONLY. TOP OF FIREBOX

TO CEILING AND WIDTH OF WALL

TOP OF FIREBOX

Joint Compound where required:

Compounds such as Durabond 90 and tapes that are heat and cracking

resilient should be used when taping and mudding seams.

Setting tiles and grouting:

If using tiles we recommend you use tiles with a dry butt joint to be

installed using a two part mortar with an acrylic latex additive, to allow

for slight movement in the normal operation of the appliance. If grout is

used between the tiles we recommend a polymer-based grout.

Primer/Paint:

For a painted surface, use a 100% acrylic latex primer and finish coat.

NOTE: Light coloured surfaces may discolour due to heat.

Loading ...

Loading ...

Loading ...