Loading ...

Loading ...

Loading ...

24

SERVICE AND MAINTENANCE

5. Remove drain plug and drain oil into a suitable container with a capacity of

no less than 64 oz.

6. Service oil filter (if equipped) as instructed in the separate Engine Operator’s

Manual.

7. Perform the previous steps in the opposite order after oil has finished

draining.

8. Refill the engine with new oil. Refer to the Engine Operator’s Manual for

information regarding the proper quantity and viscosity of engine oil.

Lubrication

WARNING

Before lubricating, repairing, or inspecting, always disengage PTO, move

shift lever into neutral position, set parking brake, stop engine and remove

key to prevent unintended starting.

Engine

Lubricate the engine with motor oil as instructed in the Engine Operator’s Manual.

Pivot Points & Linkage

Lubricate all the pivot points on the drive system, parking brake and deck lift

linkage at least once a season with light oil.

Rear Wheels

The rear wheels should be removed from the axles once a season. Lubricate the

axles and the rims with an all-purpose grease before re-installing them.

Front Axles (Hydrostatic only)

Each end of the tractor’s front pivot bar may be equipped with a grease fitting.

Lubricate with a grease gun after every 25 hours of tractor operation.

Headlights

Replace headlight bulbs as follows:

1. Fully raise the hood of the tractor.

2. Unplug the wire harness leads from the headlight socket terminals. Note

which wire connects to each terminal before disconnecting.

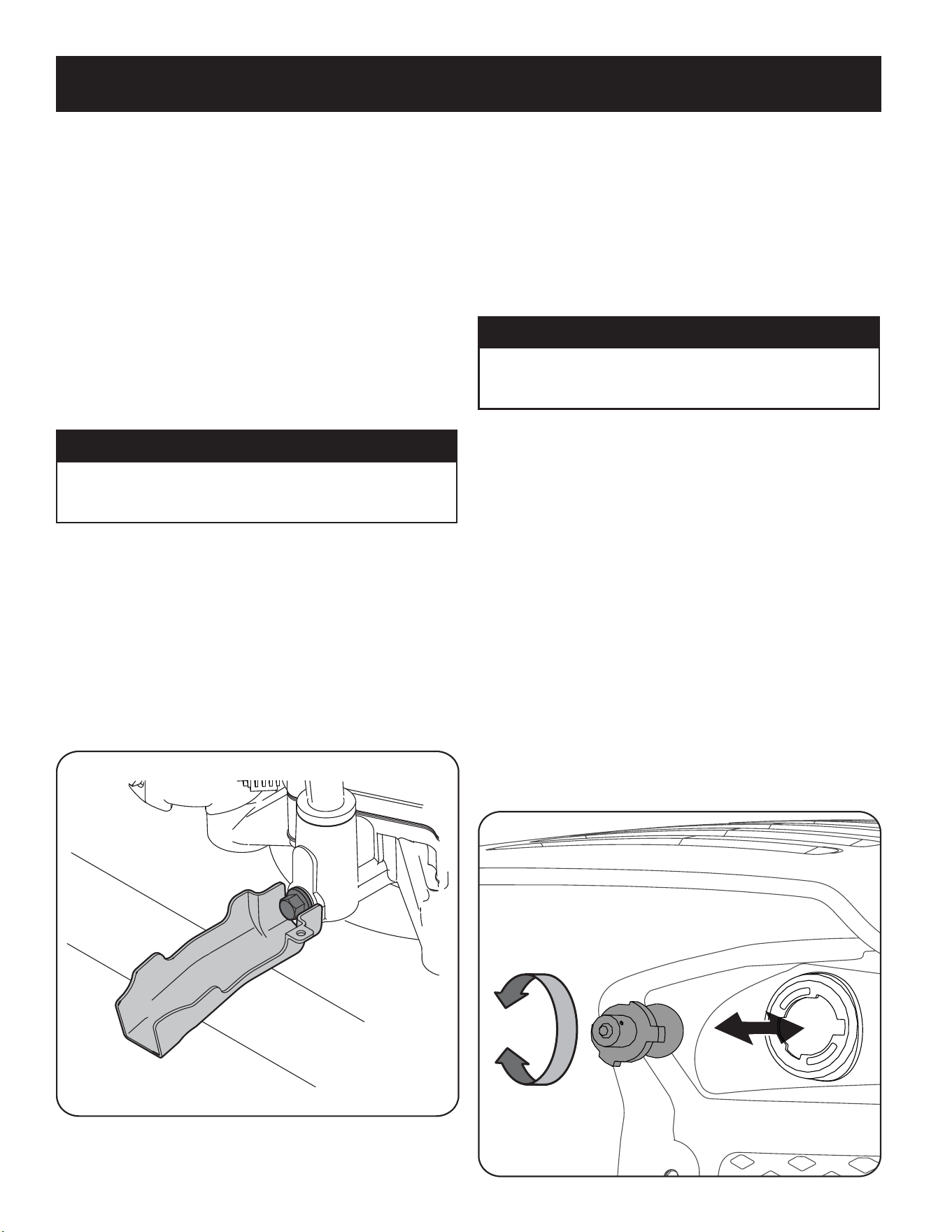

3. Rotate the socket assembly approximately a 1⁄4-turn to align the socket

tab with the reflector housing notch; then withdraw the bulb and socket

assembly from the reflector housing. See Figure 7.

Figure 7

4. Remove the oil fill cap/dipstick from the oil fill tube.

5. Push the oil drain hose (provided) onto the oil drain port. Route the opposite

end of the hose into an appropriate oil collection container with at least a 2.5

quart capacity, to collect the used oil.

6. Slightly push in on the oil drain valve and rotate counter-clockwise to open

and allow the flow of oil. See Figure 5.

7. After the oil has finished draining, push the oil drain valve back in and rotate

into the locked position. Re-cap the end of the oil drain valve to keep debris

from entering the drain port.

8. Replace the oil filter (if equipped) as instructed in the Engine Operator’s

Manual.

9. Refill the engine with new oil. Refer to the Engine Operator’s Manual for

information regarding the proper quantity and viscosity of engine oil.

Oil Drain Sleeve Models

WARNING

If the engine has been recently run, the engine, muffler and surrounding

metal surfaces will be hot and can cause burns to the skin. Exercise caution

to avoid burns.

To complete the oil change, proceed as follows:

1. Run the engine for a few minutes to allow the oil in the crankcase to warm.

Warm oil will flow more freely and carry away more of the engine sediment

which may have settled at the bottom of the crankcase. Use care to avoid

burns from hot oil.

2. Open the tractor’s hood and locate the oil drain port on the left side of the

engine.

3. Unscrew the oil fill cap and remove the dipstick from the oil fill tube.

4. Snap the small end of oil drain sleeve onto the oil sump. See Figure 6.

Figure 6

Loading ...

Loading ...

Loading ...