Loading ...

Loading ...

Loading ...

MOUNTING AN AUXILLIARY WORK TABLE

1. Fourholes are provided in the worktabte so you can easily

attach an auxiiliary work surface tothe saw if your needs

require.

2. Mounting an auxilliary table can allow you to build aLarger

support area to suit your project, and could render a

smoother work surface, as your needs require and an

auxitliary surface can give you more support close to the

blade for special cutting needs tike very small or detailed

projects.

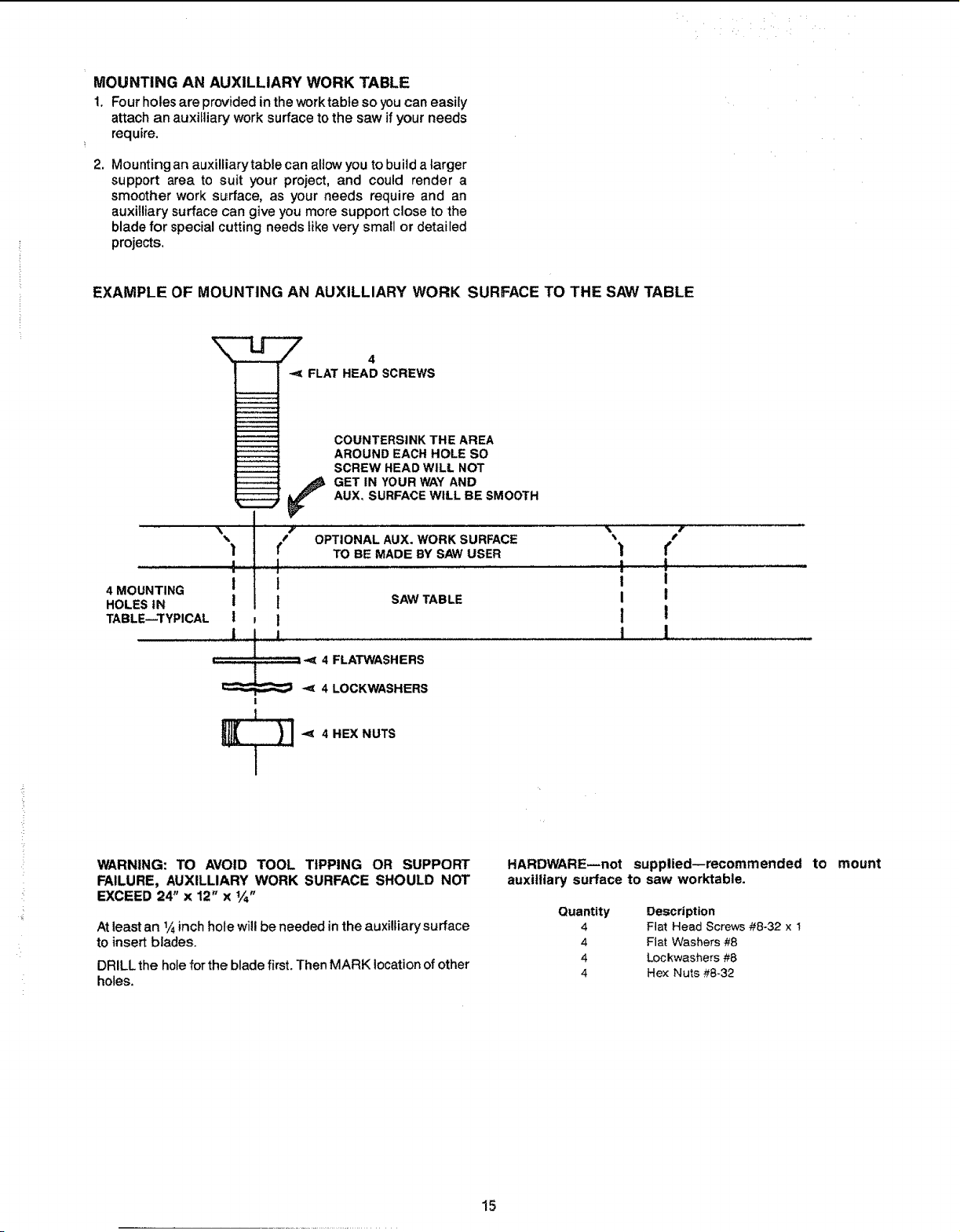

EXAMPLE OF MOUNTING AN AUXILLIARY WORK SURFACE TO THE SAW TABLE

4

-._ FLAT HEAD SCREWS

4 MOUNTING

HOLES tN

TABLE--TYPICAL

COUNTERSINK THE AREA

AROUND EACHHOLE SO

SCREW HEADWILL NOT

_ GET IN YOUR WAYAND

AUX, SURFACEWILL BE SMOOTH

I

"_ ] _'_ OPTIONAL AUX. WORKSURFACE

_'1 TO BE MADEBY SAWUSER

! , I

.......1.. I !

__ 4 FLATWASHERS

4 LOCKWASHERS

!

_"_ -,_ 4 HEX NUTS

I

% •

II !

i i

I I

I I

1 1

WARNING: TO AVOID TOOL TIPPING OR SUPPORT

FAILURE, AUXILLIARY WORK SURFACE SHOULD NOT

EXCEED 24" x 12" x _/_"

At least an 1/4inch hole will be needed inthe auxi!liary surface

to insert blades.

DRILL the hole for the blade first. Then MARK location of other

holes.

HARDWARE--not supplied--recommended to

auxitliary surface to saw worktable.

Quantity Description

4 Flat Head Screws #8*32 x 1

4 Fiat Washers #8

4 Lockwashers #8

4 He× Nuts #8-32

mount

15

Loading ...

Loading ...

Loading ...