Loading ...

Loading ...

Loading ...

SERVICE AND ADJUSTMENTS

HANDLE HEIGHT

NOTE: FACTORY ASSEMBLY HAS PROVIDED 141GH-

ESTHANDLE HEIGHT, SELECTHANDLE HEIGHT BEST

SUITED FOR YOUR TILLING CONDITIONS, HANDLE

HEIGHT WILL BE DIFFERENT WHEN TILLER DIGS

INTO SOIL

• tfalower Handle Height is desired, use ratchet with 112"

socket and extension to loosen Ihe four Bolts in the

Handle Mount and Engine Brackels (Fig 19)

• Slide Handle Panel to desired location

• Tighten the four Bolts securely

ENGINE

_ BRACKETS

\_k\\JI!l \ [/_ _ _ , NUTS(ALSO2

_-_-J_l__P'," tL',N _ ON LEFT SIDE

OPT,LLER

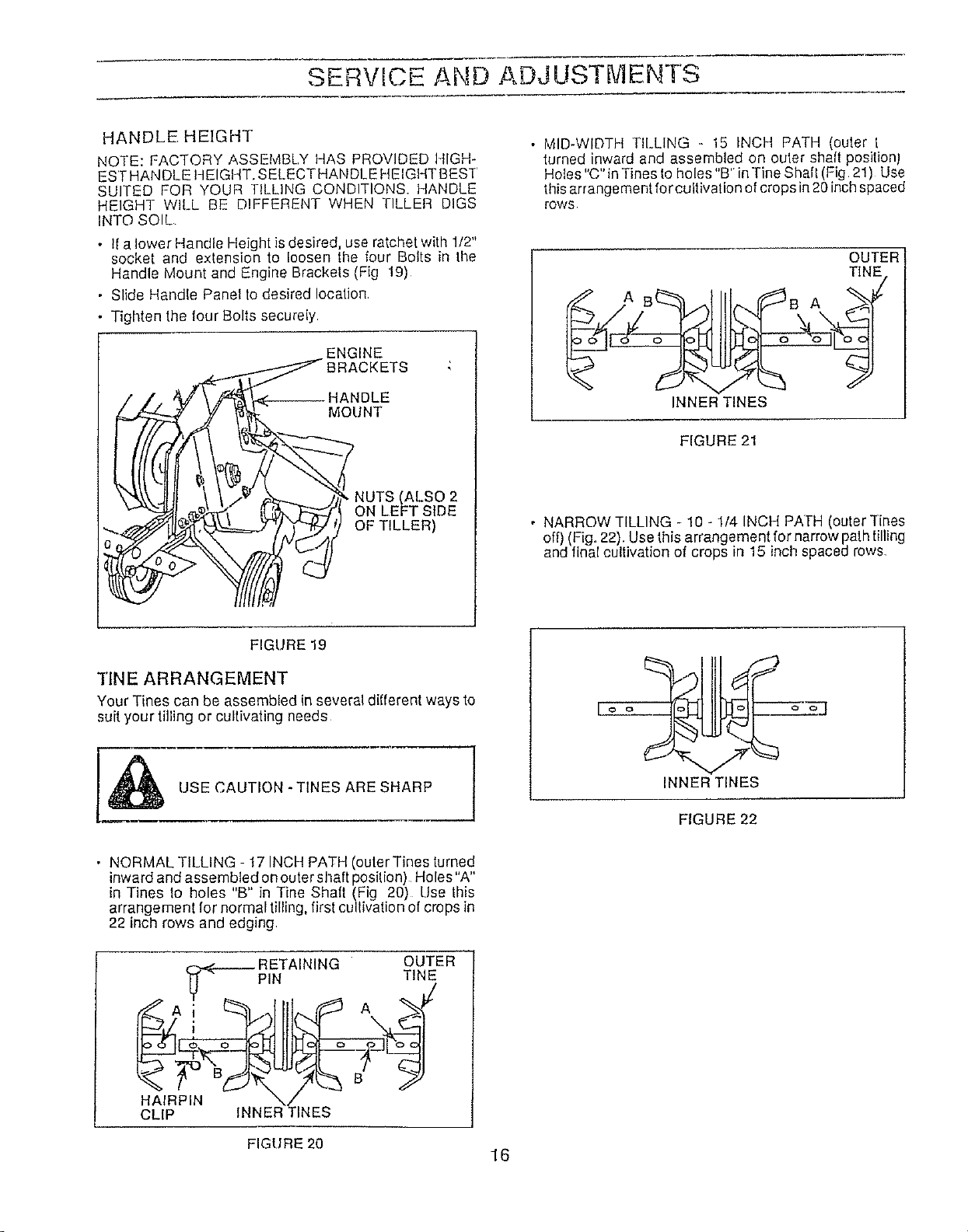

• MID-WIDTH TILLING - 15 INCH PATH (outer [

turned inward and assembled on outer shaft positionJ

Holes "C" in Tines to holes "B'"inTine Shaf! (Fig 21) Use

this arrangement forcultivation of crops in 20 inchspaced

rOWS

OUTER

TINE

AB B A

INNER TINES

FIGURE 21

• NARROW TILLING - 10 -1/4 INCH PATH (outer Tines

off) (Fig. 22). Use this arrangement for narrow pathtilling

and final cultivation of crops in 15 inch spaced rows

FIGURE 19

TINE ARRANGEMENT

Your Tines can be assembled in several different ways to

suit your tilling or cultivating needs

[I_ USE CAUTION -TINES ARE SHARP

[o o_ o ol

INNER TINES

FIGURE 22

• NORMAL TILLING - 17 INCH PATH (outer Tines turned

inward and assembled on outer shaft position) Holes"A"

in Tines lo holes "B" in Tine Shall (Fig 20) Use this

arrangemenl for normal tilling, first cultivation of crops in

22 inch rows and edging.

RETAINING OUTER

PIN TINE

HAIRPIN \/

CLIP INNER TINES

FIGURE 20

16

Loading ...

Loading ...

Loading ...