Loading ...

Loading ...

Loading ...

CUSTOMER RESPONSIBILITIES

CHECK FOR DAMAGED/WORN PARTS

The following damaged/worn parts should be referred to

your Sears Serv{ce Center,

NOTE: It is normal for a small amount of oil to appear

under the saw after engine stops Do not confuse this with

a leaking oil tank,.

= On/Stop Switch - ensure on/stop switch functions prop-

erly by moving the switch to the "stop" position and

assure that engine stops, then restart your engine and

continue.,

= Fuei Tank - discontinue use of chain saw if fuel tank

show signs of damage or leaks,

. Oil Tank - discontinue use o! chain saw ifoil tank shows

signs of damage or leaks.

= Chain Catcher - replace chain catcher if bent, cut, or

damaged in any way.

CLEAN UNIT AND LABELS

. Clean the unit using a damp cloth with a mild detergent

• Wipe off the unit with a clean dry cloth,

CLEAN AIR FILTER (Fig. 40)

A dirty air filter decreases the life and performance of the

engine and increases fuel consumption and harmful

emissions

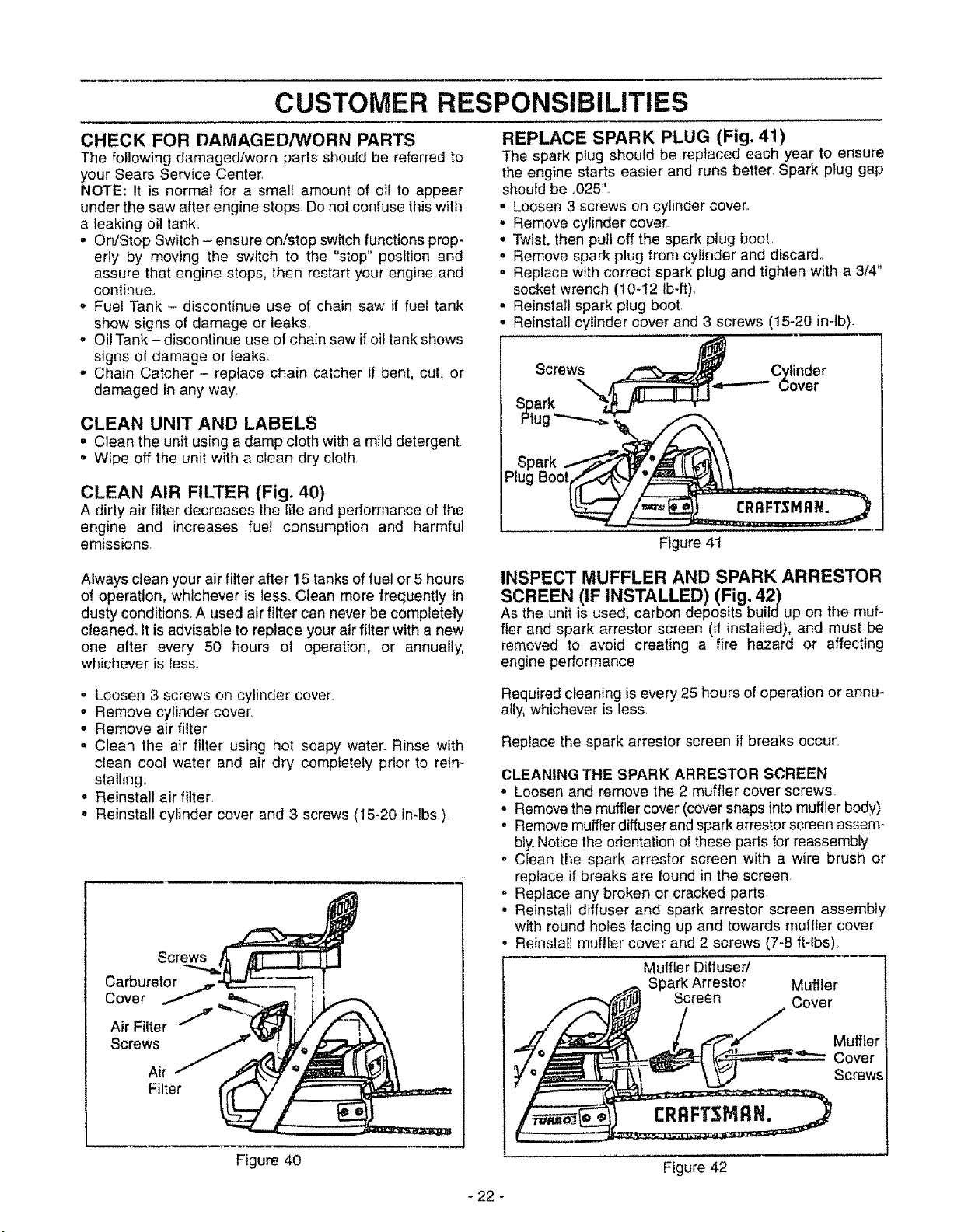

REPLACE SPARK PLUG (Fig. 41)

The spark plug should be replaced each year to ensure

the engine starts easier and runs better, Spark plug gap

should be .025".

• Loosen 3 screws on cylinder cover.

• Remove cylinder cover

o Twist, then pull off the spark plug boot..

• Remove spark plug from cytinder and discard.

• Replace with correct spark plug and tighten with a 3/4"

socket wrench (10-12 Ib-ft),,

• Reinstall spark plug boot,

• Reinstall cylinder cover and 3 screws (15-20 in-lb).

Screws Cylinder

_over

CRnFT_;MRN.

Figure 41

Always clean your air filter after 15 tanks of fuel or 5 hours

of operation, whichever is less. Clean more frequently in

dusty conditions. A used air filter can never be completely

cleaned,, it is advisable to replace your air filter with a new

one alter every 50 hours of operation, or annually,

whichever is less.

INSPECT MUFFLER AND SPARK ARRESTOR

SCREEN (IF INSTALLED) (Fig. 42)

As the unit is used, carbon deposits build up on the muf-

fler and spark arrestor screen (if installed), and must be

removed to avoid creating a fire hazard or affecting

engine performance

. Loosen 3 screws on cylinder cover.

° Remove cylinder cover,

• Remove air filter

. Clean the air filter using hot soapy water. Rinse with

clean cool water and air dry completely prior to rein-

stalling.,

• Reinstall air filter,

. Reinstall cylinder cover and 3 screws (15-20 in-tbs).

Screws

Carburetor .._,

Cover /

Air Filter

Screws

Air

Filter

Required cleaning is every 25 hours ofoperation or annu-

ally, whichever is less

Replace the spark arrestor screen if breaks occur.,

CLEANING THE SPARK ARRESTOR SCREEN

. Loosen and remove the 2 muffler cover screws

• Remove the muffler cover (cover snaps intomuffler body)

= Remove muffler diffuser and spark arrestor screen assem-

bly,Notice the orientation of these parts for reassembly

• Clean the spark arrestor screen with a wire brush or

replace if breaks are found in the screen

• Replace any broken or cracked parts

• Reinstall diffuser and spark arrestor screen assembly

with round holes facing up and towards muffler cover

• Reinstall muffler cover and 2 screws (7-8 ft-lbs),

Muffler Diffuser/

Spark Arrestor Muffler

Screen Cover

Muffler

Cover

Screws

Figure 40

- 22 -

Figure 42

Loading ...

Loading ...

Loading ...