Loading ...

Loading ...

Loading ...

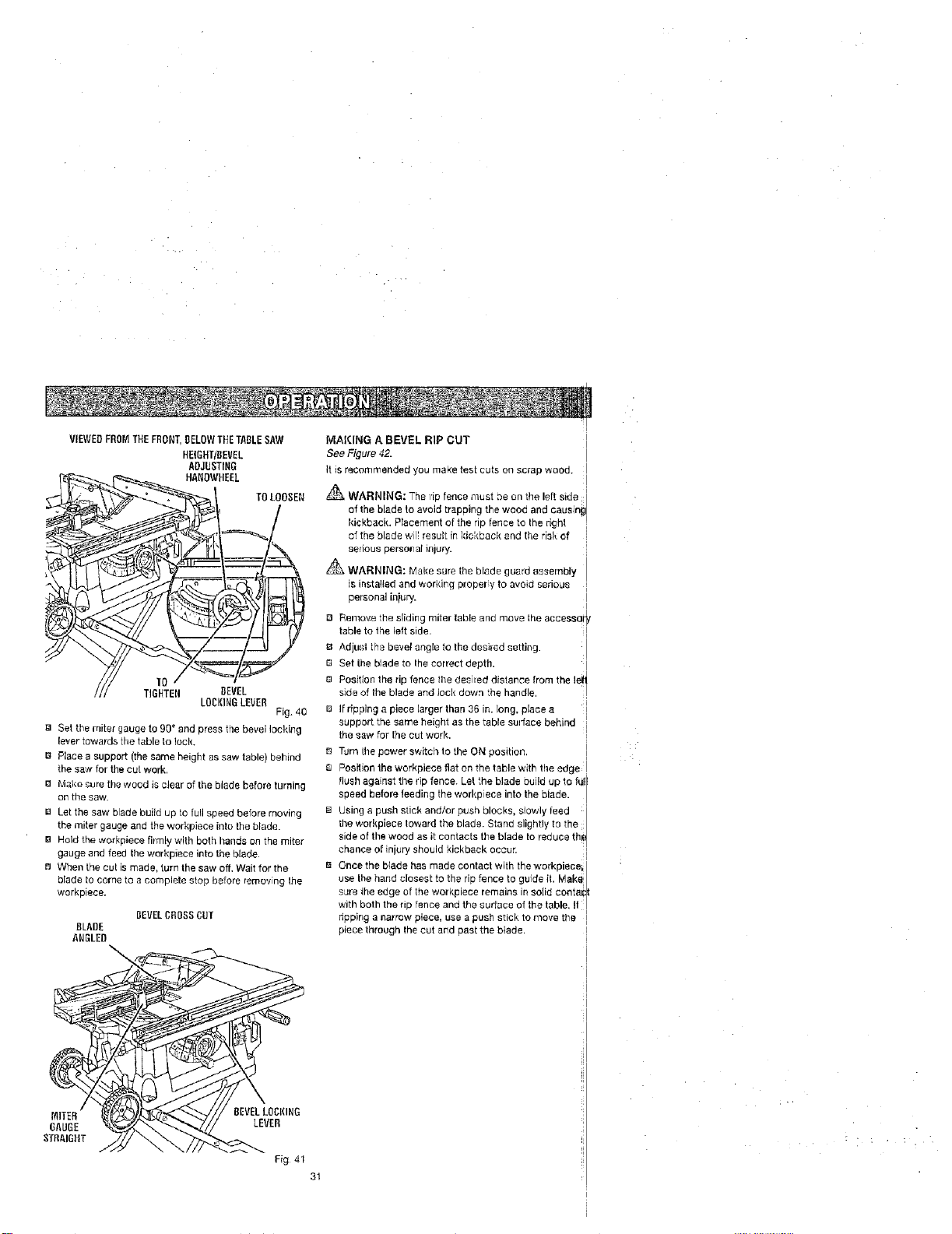

VIEWEDFROr_THEFRONT,BELOWTHETABLESAW

HEIGHTIBEVEL

ADJUSTING

HANOWHEEL

TOLOOSEN

10

TIGtiTEN BEVEL

LOCKINGLEVER

Fig. 40

_] Set the miter gauge to 90° and press the bevel locking

lever towards the table to lock,

B Place a support (the same height as saw table) behind

the saw for tire cut work.

Make sure the wood is clear of the blade before turning

on the saw.

Let the saw blade build up to full speed before moving

the miter gauge and the workpiece into the blade.

El Hold the workpiece firmly with both hands on the miter

gauge and feed the workpiece into the blade

When the cut is made, turn the saw off, Wait for the

blade to come to a complete stop before removing lhe

workpiece.

DEVELCROSS CUT

BLADE

ANGLED

BEVELLOCKING

LEVER

MAKING A BEVEL RiP CUT i

See Figure 42. I

It isrecommended you make test cuts oil scrap wood. I

I

WARNING: The np fence must oe on the let. side I

of the blade to avoid trapping the wood and c_usinil

kickback. PIacement of the rip fence to the righl I

of the blade will result in kickback and the risk of

seedus personal inlury.

_ WARNING: Make sure the blade guard assembly

is installed and working proper y to avoid serious

personal injury.

, pN Remove ,he sliding miter table and move the accessoi

table to the left side.

Adjust the bevel angle to the desired setting.

D Set the blade to Ihe correct depth,

Position the rip fence the desired distance from the lei'

side of the blade and lock down the handle,

Ifripping a piece larger than 36 in. long, place a

support the same height as the table sutfface behind i

the sew for lhe cut work.

r_ Turn lhe power switch to the ON position,

Position the workpiece flat on the table with tt]e edge

flush against the rip fence. Let the blade ouild up to full

speed before feeding the workpiece into the blade.

Using a push stick and!or push blocks, slowly feed

the workpiece toward the blade. Stand slightly t_ the

side of the wood as it contacts the blade to reduce th

chance of injury should kickback occur.

Once the blade has made contact with the workpieee_ I

use the hand closest to the rip fence to guide it. Mak_

sJre ihe edge of the workpiece remains in solid conta_;

with boh he r p once and the surface of he tab e. t

ripping a narrcw piece, use a push stick to move the

piece through the cut and past the biade.

Fig 41

31

Loading ...

Loading ...

Loading ...