Loading ...

Loading ...

Loading ...

10.1 DAILY MAINTENANCE

Inspect each operating part ot ensure the condition of lubrication.

Examine each component for abnormal situations.

Clean and remove obstacles around the machine to prevent damage and maintain the safety of

the operator.

Keep the machine clean after daily use and lubricate moving parts to prevent rust.

Watch the machine for any unusual events; stop and repair immediately.

10.2 REGULAR MAINTENANCE

Use clean cotton or soft gauze to clean each part of the machine.

Check the motion of the machine’s head and fixture are smooth.

Check tightness of each nut and bolt.

10.3 MAINTENANCE OF CUTTER

Use a rag while installing or unloading the cutter to prevent the cutter falling and causing injuries

or damage to the cutter.

Keep the cutter in a wooden or plastic box when you don’t need it, in order to maintain the sharp

blade.

Pay extra attention on cutter rotating direction. Incorrect direction might cause damage to the

cutter or injury.

Put the cutter and workpiece in place before you turn on the machine. After turning on the

machine, the cutter will get close to the workpiece and mill it.

Sharpen or replace the cutter as soon as it becomes dull.

10.4 ATTENTION ITEMS FOR ACCESSORIES

Please keep the taper shank clean.

Please keep the taper shank and cutter in order and keep the same cutter together.

Draw bar and chuck have their own wrenches. For your convenience, please keep the wrenches

near by the machine and never operate the machine with inappropriate tools.

Please use wrench to tighten the nuts and never use other tools.

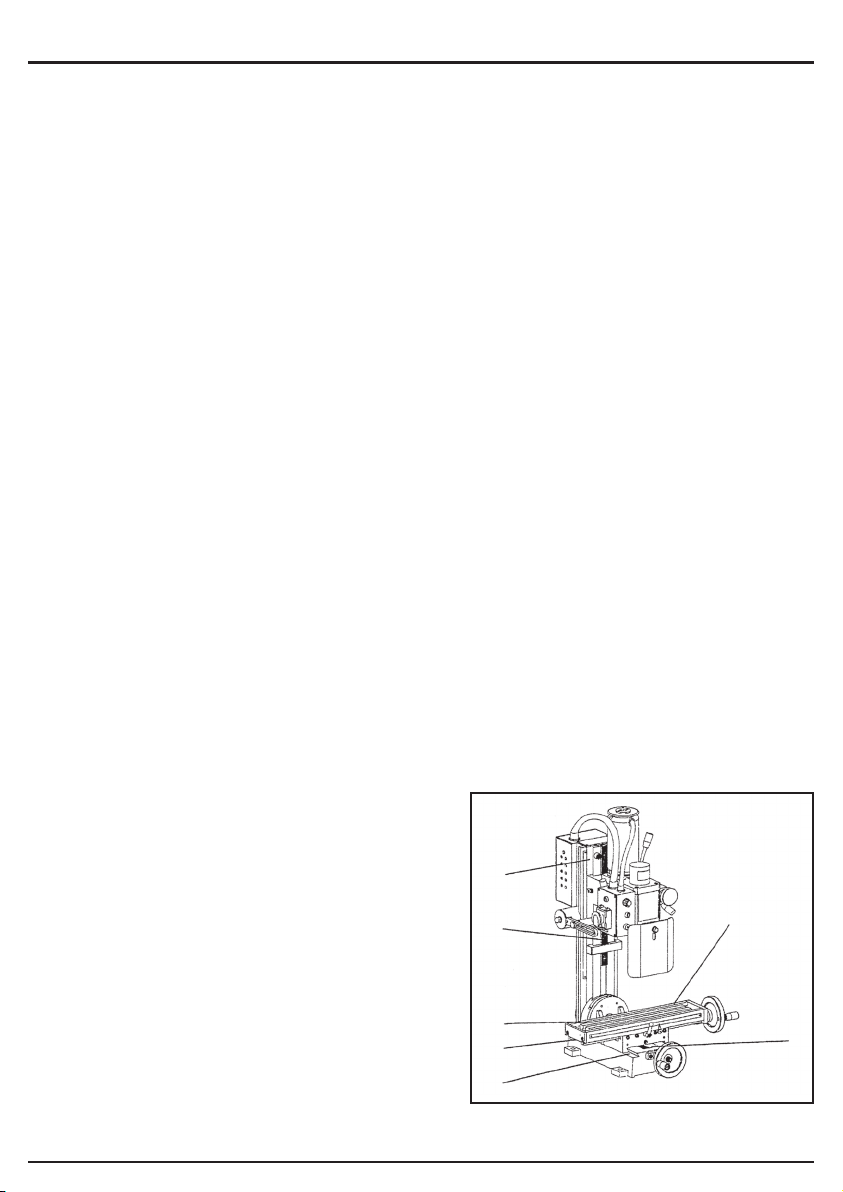

10.5 MECHANICS LUBRICATION

In order to ensure precision, maintain lubrication

on contact faces.

The following are the item the needs to be

lubricated on this machine.

Use lubricating oil:

(1) Base and saddle seat slide face.

(2) Saddle seat and worktable slide fence.

(3)

Headstock sear and connecting strut slide face.

(4) Headstock and spindle box slide face.

Use lubricating grease:

(5) X-axis feeding screw (saddle seat).

(6) Y-axis feeding screw (working table).

(7) Z-axis feeding gear rack (fuselage).

After working, clean the worktable and lubricate

with a little lubricant to protect the worktable.

– 18 –

10. MAINTENANCE

(7)

(4)

(3)

(5)

(6)

(1)

(2)

Loading ...

Loading ...

Loading ...