Loading ...

Loading ...

Loading ...

1514

CULTIVATOR EDGER PRUNING SAW HEDGE TRIMMER BRUSHCUTTER

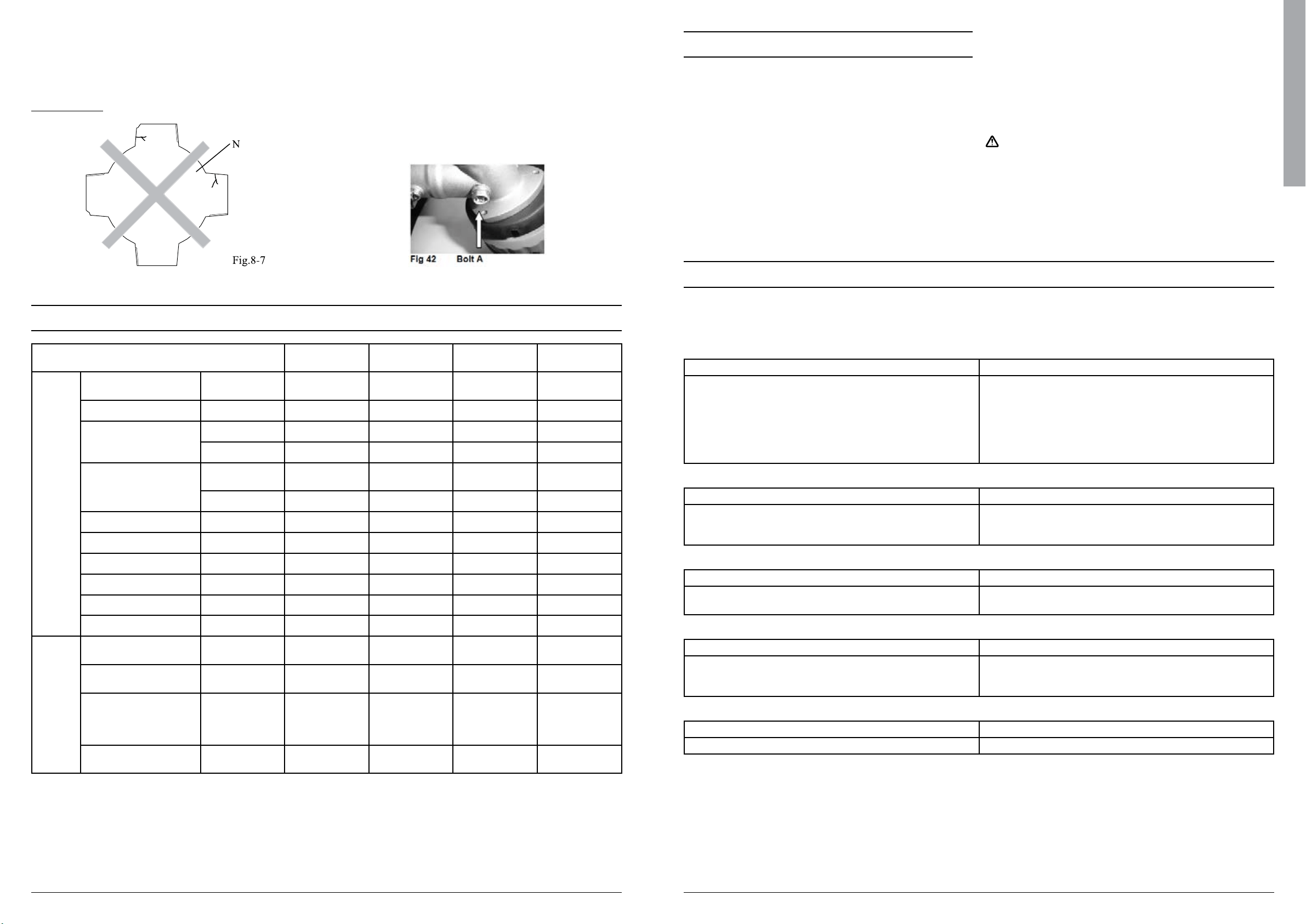

Inspecting the cutting blade

When the cutting edge becomes dull, the cutting blade will fail to

cut cleanly and can exhibit blade thrust during operation. Using a

broken, cracked or deformed blade carries a risk of blade fragments

flying off during operation.

Inspection timing - Before and after operation

1. Check that the cutting blade (N) as been correctly installed and

that the blade clamping nut is not loose.

(See [5-2] Mounting the cutting blade or nylon trimmer.)

2. 2. Check the cutting blade (N) or excessive wear, breakage,

cracks or deformation. If any such problems are found, replace

the blade with a new one. Never use a damaged blade.

Gear Case

• Remove the bolt A on the gear case Fig 42, top up the gearbox

using Lithium grease and refit the bolt.

Long-term Storage

If the machine will not be started for 30 days or longer, maintain and

store the machine as follows:

1. Remove debris from the machine. Check the machine for

damage and loose screws. Correct any problems so that the

machine can be restarted later without a problem.

2. Drain the fuel from the fuel tank. Start the engine and run it

until no fuel remains in the carburetor. (The engine will stop

automatically when no fuel remains.)

3. Allow the engine to cool. Remove the spark plug and squirt a

small amount of fresh engine oil into the spark plug hole. Slowly

pull the recoil starter cord two or three times.

4. Reinstall the spark plug. Slowly pull the recoil starter cord and

release it when you feel resistance. (This closes the intake and

exhaust ports.)

5. Lightly wipe the external surface of the engine with cloth. Then,

store the machine in a dry dust-free location where no open fire

is present.

6. Before storing the machine, clean the cutting blade and check

for any irregularities. Install the blade cover provided as a

standard accessory.

7. Store the drained fuel in a safe container and keep it in a cool,

dry room.

CAUTION

Do not store the machine for a prolonged period with fuel remaining

in the fuel tank. Impurities in the fuel will deteriorate, adversely

affecting the carburetor and fuel filter and possibly causing an

engine malfunction. Always fully drain the fuel before storing the

machine.

Inspection and Maintenance Checklist

Checkpoints Before and after

operation

Every 20 Hours

of operation

Every 50 hours of

operation

Every 100 hours

of operation

Engine

Loose screws, nuts and

bolts

Inspect

○

Fuel leaks Inspect

○

Air cleaner

Inspect

○

Clean

○*1

Spark plug

Inspect and

adjust

○

Replace

○

Engine cooling fins Inspect and clean

○

Muffler / exhaust port Inspect and clean

○

Clutch shoe Inspect

○*2

Fuel filter Clean

○

Fuel tank Clean

○

Carburetor Inspect

○

Entire

Unit

Loose screws, nuts and

bolts

Inspect

○

Broken, worn or missing

parts

Inspect

○

Breakage, wear, cracks or

deformation f the cutting

blade or nylon trimmer;

loose clamping nuts

Inspect

○

Grease in angle

transmission

Replenish grease

○

*1 When using the machine in a dusty location, clean the air cleaner after every 10 hours of operation.

*2 Clutch shoe replacement requires an appropriate tool kit and special maintenance techniques. We recommend that you ask your dealer

to replace the clutch.

Troubleshooting

This troubleshooting section describes possible causes and remedies for problems you might encounter during operation of the machine.

If a problem persists after you have attempted the solutions recommended in this section, contact your dealer for technical assistance. Do

not attempt to disassemble the machine.

Engine does not start

Typical cause Solution

• The stop switch is in the STOP position.

• The fuel has deteriorated or is of poor quality.

• The carburetor is flooded with excess fuel.

• The muffler exhaust pipe opening is blocked.

• The spark plug electrodes are fouled.

• Set the stop switch to the START position.

• Use fresh fuel of the correct grade.

• Turn the choke lever to the position opposite the START

position. Pull the recoil starter cord repeatedly.

• Using a screwdriver or other appropriate tool, remove the

deposited carbon from the muffler.

• Clean the electrodes or replace the spark plug.

Engine does not accelerate

Typical cause Solution

• The fuel has deteriorated or is of poor quality.

• The muffler exhaust pipe opening is blocked.

• Use fresh fuel of the correct grade.

• Using a screwdriver or other appropriate tool, remove the

deposited carbon from the muffler

Engine stalls when the throttle trigger is released

Typical cause Solution

• The idle speed is too low. • Adjust the idle speed with the idle-speed adjuster on the

carburetor

Cutting blade continues to rotate after the throttle trigger is released

Typical cause Solution

• The idle speed is too high.

• The throttle linkage has little or no play.

• Adjust the idle speed with the idle-speed adjuster on the

carburetor.

• Adjust the play on the throttle linkage.

Engine speed fluctuates

Typical cause Solution

• The fuel filter is clogged. • Clean or replace the fuel filter.

Loading ...

Loading ...

Loading ...