Loading ...

Loading ...

Loading ...

1110

CULTIVATOR EDGER PRUNING SAW HEDGE TRIMMER BRUSHCUTTER

the cords should stick out 15 cm each side,

8. Pull the cords to free them from the notches, refit the spool

cover.

Never use cutting device other than those supplied by the

manufacturer.

(Steel cord is never allowed).

Always use original spare parts in order to benefit from

continuous warranty.

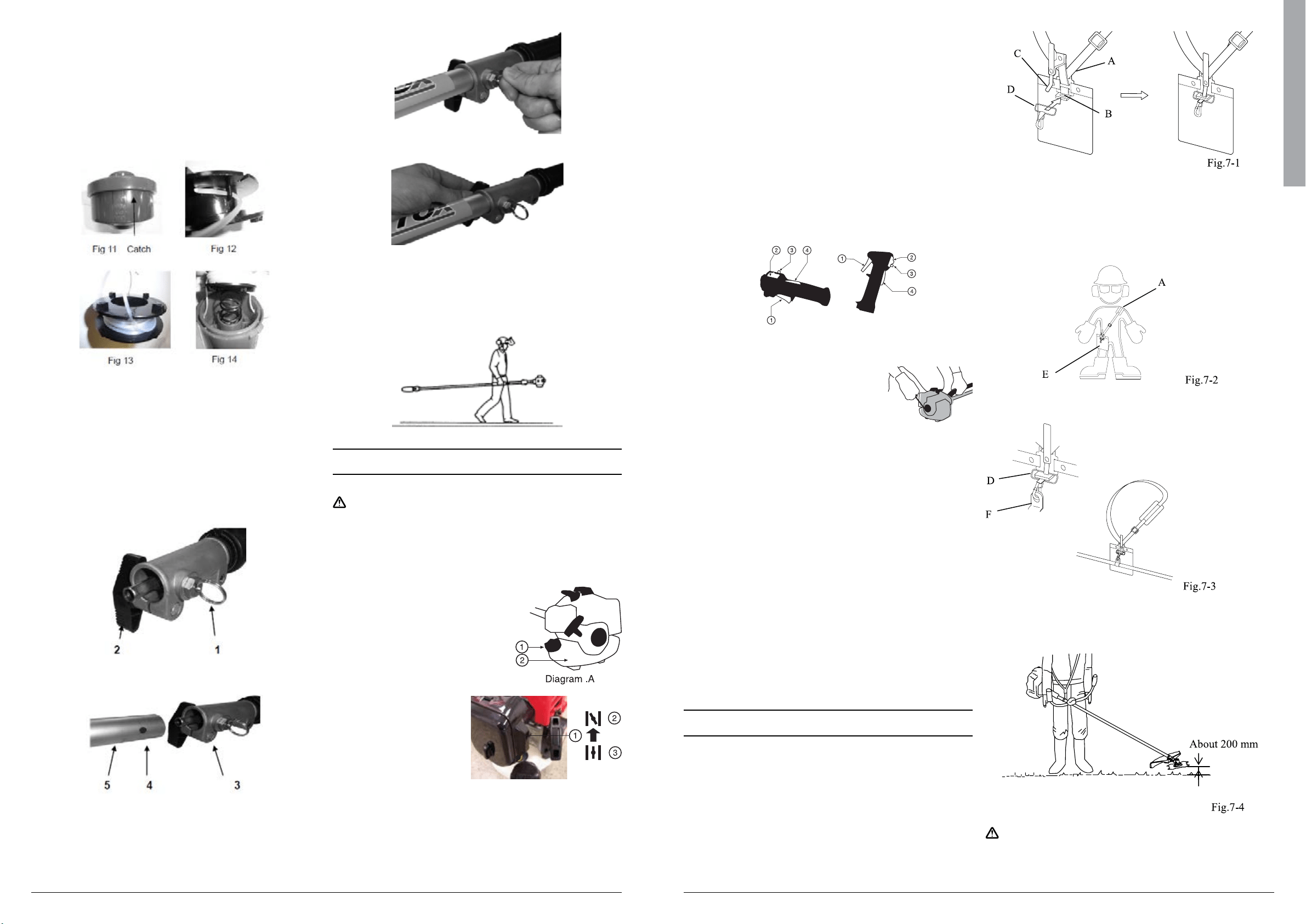

Attaching The Tools To The Drive Shaft Assembly

• Rest the power unit/shaft assembly on a flat firm surface.

• Ensure that the clamping wing nut (2) is loose, pull out locator

pin (1).

• Carefully fit attachment drive shaft assembly (5) into coupler (3).

• After the attachment drive shaft is in the coupler, release the

locator pin (1).

• Turn the attachment drive shaft until the locator pin engages

with the locating hole (4) in the drive shaft, when this has

happened it will not be possible to twist the drive shaft.

• Secure the drive shaft by tightening the clamping wing nut (2).

Transportation

• Never transport the multi-tool with the engine running. An

engine that’s running could be accidently accelerated causing

the attachment to operate.

• When carrying by hand, the engine should be pointing forward.

Starting and Stopping the Engine

Starting the Engine

CAUTION

Do not pull the starter cord all the way out and do not let go of the

starter handle when the cord is extended, this can damage the

starter mechanism.

Before starting the engine, inspect the entire unit for loose fittings or

fuel leaks, and verify that the cutting attachment is properly installed

and securely fastened.

Place the unit on a flat, firm place. Keep

the cutting head clear of any obstructions.

1. Check that there is fuel in the tank

and that the fuel cap is screwed on

tightly.

(1) Cap

(2) Fuel tank

2. When starting a cold

engine move the choke

lever (behind the air cleaner

cover) to the closed

position.

(1) Choke lever

(2) Closed

(3) Open

3. If the engine has been running and is still warm, move the

choke lever to the open position.

4. Press the priming bulb under the carburettor repeatedly until

excess fuel can be seen returning to the tank through the clear

fuel return pipe.

5. Slide the ignition switch (2) on the trigger grip away from the

STOP position (See Diagram .C on the next column).

6. To set the throttle in the start position.

- Depress the safety lever (4)

- Squeeze the throttle lever (1) fully.Hold down the starting

button (3) while releasing the throttle lever.

- The throttle lever will be held partly open until it is squeezed

again.

(1) Throttle lever

(2) Ignition Switch

(3) Starting button.

(4) Safety Lever

BC 230B S2, BC 260 S2 and

BC 260B S2

BC 325 S2

Diagram .C

7. While holding the unit firmly, pull out the

starter rope quickly.

8. After the engine has started, open the

choke gradually.

9. Allow the engine to run for 2 to 3 minutes

to warm up before starting work.

NOTE

Overchoking

• Should the engine become flooded due to over-choking set the

ignition switch to the STOP (O) position Fig 35, unscrew the

spark plug, wipe it dry or replace, pull the recoil starter several

times without the spark plug in place and with the choke in the

open position. This will help clean and ventilate the combustion

chamber.

STOPPING THE ENGINE

• Set the engine to idling by releasing the throttle lever.

• Set the ignition switch to the STOP (O) position.

• If the engine fails to stop, set the choke lever to the closed

position to stall the engine; do not use the machine until the

ignition switch is repaired.

RUNNING IN

• During the first ten hours of work, avoid running the engine

at maximum speed for a prolonged period until all the

components have bedded in. After the engine has been run-in,

it will reach its maximum power.

Wearing the Harness

The harness has a quick-release mechanism that allows

you to immediately release the machine from the harness

in an emergency.

Attaching the side hook

NOTE

If side hook (D) has disengaged from hook (B), engage it.

1. Insert hook (B) into side hook (D).

2. While holding hook (B) and side hook (D) in place,

insert stopper (C) into the hole on hook (B).

Adjusting the harness

1. As shown in the diagram, adjust the harness (A) so that

hip pad (E) is against your right hip. (Fig.7-2)

2. Before starting to work, attach the side hook (D) to the

suspension point (F) on the shaft tube. (Fig.7-3)

Recommended working position

CAUTION

If releasing both hands from the handle, use extreme care. Suddenly

Diagram .B

Loading ...

Loading ...

Loading ...