Loading ...

Loading ...

Loading ...

98

CULTIVATOR EDGER PRUNING SAW HEDGE TRIMMER BRUSHCUTTER

Blade

• The cutting attachments of the brushcutter rotate

counterclockwise. Cut a 1.5-meter arc from right to left. Within

this arc, maintain the cutting blade at a consistent height above

the ground. Advance slowly and gradually, beginning with the

right foot.

• Cut brush with the arc α on the cutting blade. If the arc β on

the rotating blade hits a solid object, a cutting blade running

at high speed will thrust toward the operator, creating a very

dangerous situation. (Fig.3-5)

11. Abnormal noise and vibration

• If the machine suddenly exhibits abnormal noise or vibration,

immediately shut off the engine.

• Possible causes of sudden noise or vibration include loose

screws and damage to the cutting blade or other components.

Check the entire machine for any sign of a problem.

• After the cause has been found, do not use the machine until

you have completed the repair.

Fuel and Oil

DANGER

• Do not handle fuel near open fire (open flame, lit cigarette,

stove, etc.) or electrical spark (from electrostatic discharge,

welding spark, or switch or battery short-circuit). Doing so can

cause the fuel to ignite, resulting in a fire.

• Do not refuel while the engine is running or while the engine is

still hot after shutting off the machine. Allowing fuel to splash on

a hot engine can result in a fire.

• Refuel the machine outdoors or in a well-ventilated location.

• After refueling, securely close the fuel cap and thoroughly wipe

off any spilled fuel. Spilled fuel can ignite after the machine is

running, leading to a fire.

NOTICE

Refer to the engine instruction manual for more details.

2-stroke engine

Fuel

When fueling a 2-stroke engine, use a fuel-oil mixture of

gasoline and 2-stroke engine oil.

• When mixing gasoline with two-cycle engine oil, use only

gasoline which contains NO ETHANOL or METHANOL (types

of alcohol). Use branded 91 octane or higher unleaded gasoline

known to be of good quality. This will help avoild possible

damage to the engine fuel lines and other engine parts.

• 2-stroke engine oil required

Use high-quality JASO FC class 2-stroke engine oil.

NOTICE

Pour the engine oil into a mixing vessel. Add gasoline

and mix thoroughly.

CAUTION

• Do not mix the engine oil and fuel in the fuel tank of the engine.

• Fuel-oil mixtures degrade over time. We recommend that you

prepare only the amount of the fuel-oil mixture you will use in

the short term. Do not use a fuel-oil mixture that was prepared

more than a week earlier. A degraded fuel-oil mixture can

damage the engine.

• Do not use a fuel-oil mixture containing an incorrect proportion

of engine oil. Doing so can cause an engine malfunction or

engine seizure.

When using a mineral oil:

Mix ratio 25:1

Gasoline litres: 1 2 3 4 5

2 cycle oil mL: 40 80 120 160 200

When using a semi-synthetic mineral oil:

Mix ratio 40:1

Gasoline litres: 1 2 3 4 5

2 cycle oil mL: 25 50 75 100 125

IMPORTANT

Two-stroke fuel may seperate. Shake the fuel container thoroughly

before each use. Stored fuel ages. Do not mix more fuel than you

expect to use within a month.

Assembly

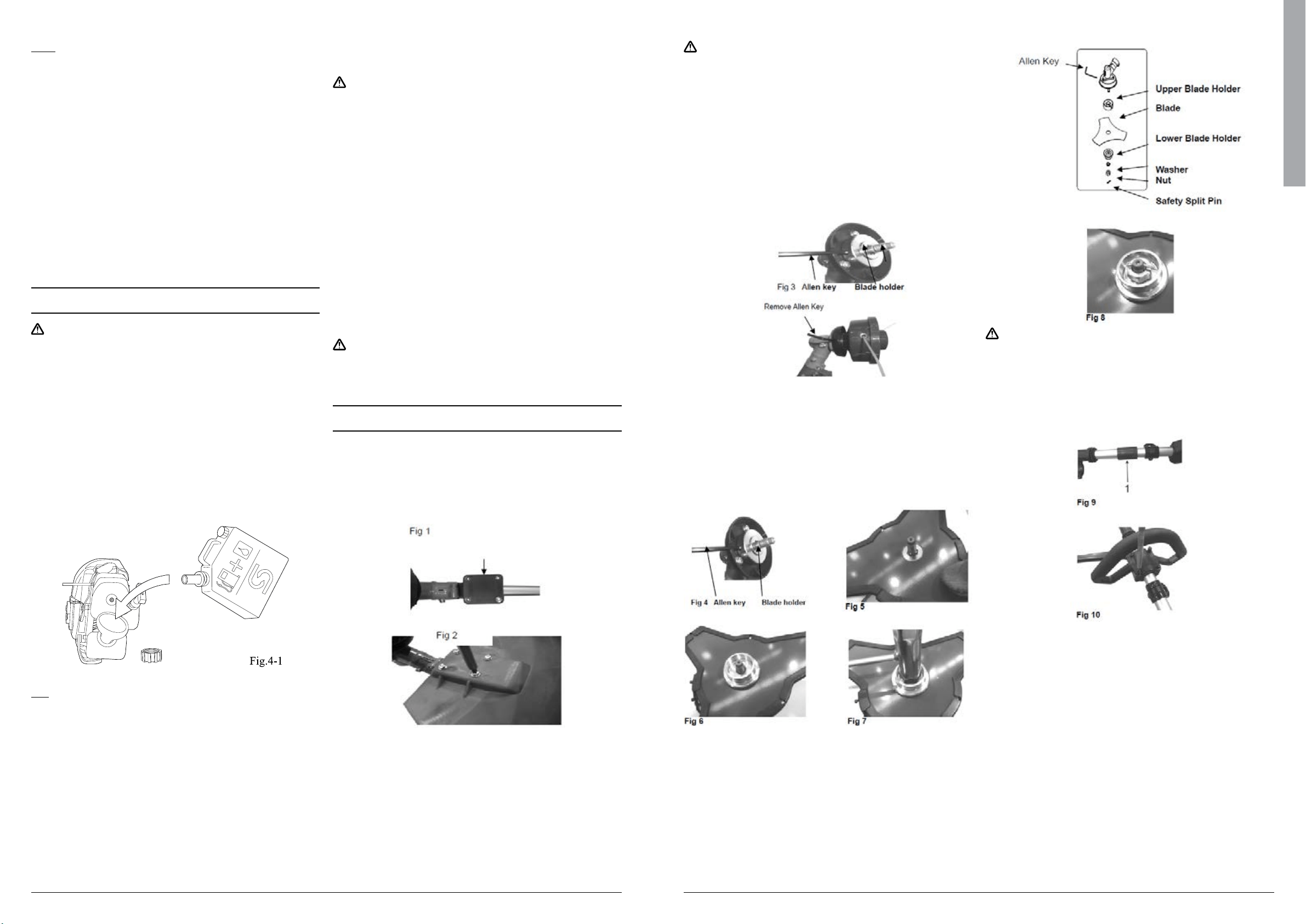

Installation of the guard

Place the brush cutter with the head facing up.

Line up the 4 screw holes in the guard with the bracket (Fig 1) on

the shaft.

Insert 4 screws through the guard into the captive nuts in the

bracket (Fig2) and tighten.

WARNING

The blade fitted to the guard is sharp and can cause injury, always

wear gloves

Installation of the nylon head

1. Lay the brush cutter on its back with the gear box shaft facing

up.

2. Insert the Allen key onto the hole in the gear box cover.

3. Rotate the gear box shaft until the Allen key slides into the

blade holder (Fig 3).

4. Screw the nylon head anti-clockwise (turn left) onto the

threaded shaft at the end of the gear box.

5. Make sure that the nylon head is securely locked in position.

6. Remove the Allen key.

Installation of the 3 tooth blade

Always wear gloves when touching the blade

1. Lay the brush cutter on its back with the gear box shaft facing

up, insert the Allen key into the hole in the gear box cover.

2. Rotate the gear box shaft until the Allen key slides into the

blade holder (Fig 4).

3. Place the 3 tooth blade on the upper blade holder, centring the

blade on the raised centre (Fig 5).

4. Fit the lower blade holder (Fig 6) and washer.

5. Screw the nut anti-clockwise (turn left) and tighten using the

spanner provided (Fig 7).

6. Make sure that the blade is completely and safely locked in

position, and there is no space between the blade and the

blade holder.

7. Fit split pin (fig 8).

8. Remove the Allen key..

The blade MUST be correctly positioned on the upper

blade clamp otherwise SERIOUS DAMAGE AND INJURY TO

PERSONS AND PROPERTY could result.

Fitting the handle

Fix the loop-handle to the shaft over the rubber block provided (1

Fig 9) Adjust to a comfortable working position then tighten the

fixing screws securely (Fig 10).

Replacing the nylon cord

Check thoroughly if the nylon head is worn out before replacing the

cord. If you can see serious traces of wear, you must replace the

complete nylon head.

1. Stop the engine

2. Open the nylon head by pushing on the catch (Fig 11) and

twisting the cover anti-clock wise

3. Pull the bobbin out of the nylon head and take out the rest of

the nylon cords.

4. Cut the cords, 2.4mm Ø and 5 meters long in two equal

lengths.

5. Make a loop folded at each end of the two nylon cords and

insert those in the two holes provided for on the bobbin (Fig12)

and wind it clockwise maintaining an even and firm tension

onto the bobbin, being careful not to twist the line.

6. After winding the cord, insert both ends into the notches on the

bobbin (Fig13).

7. Introduce each end of the cords in the holes provided (Fig 14),

Loading ...

Loading ...

Loading ...