Loading ...

Loading ...

Loading ...

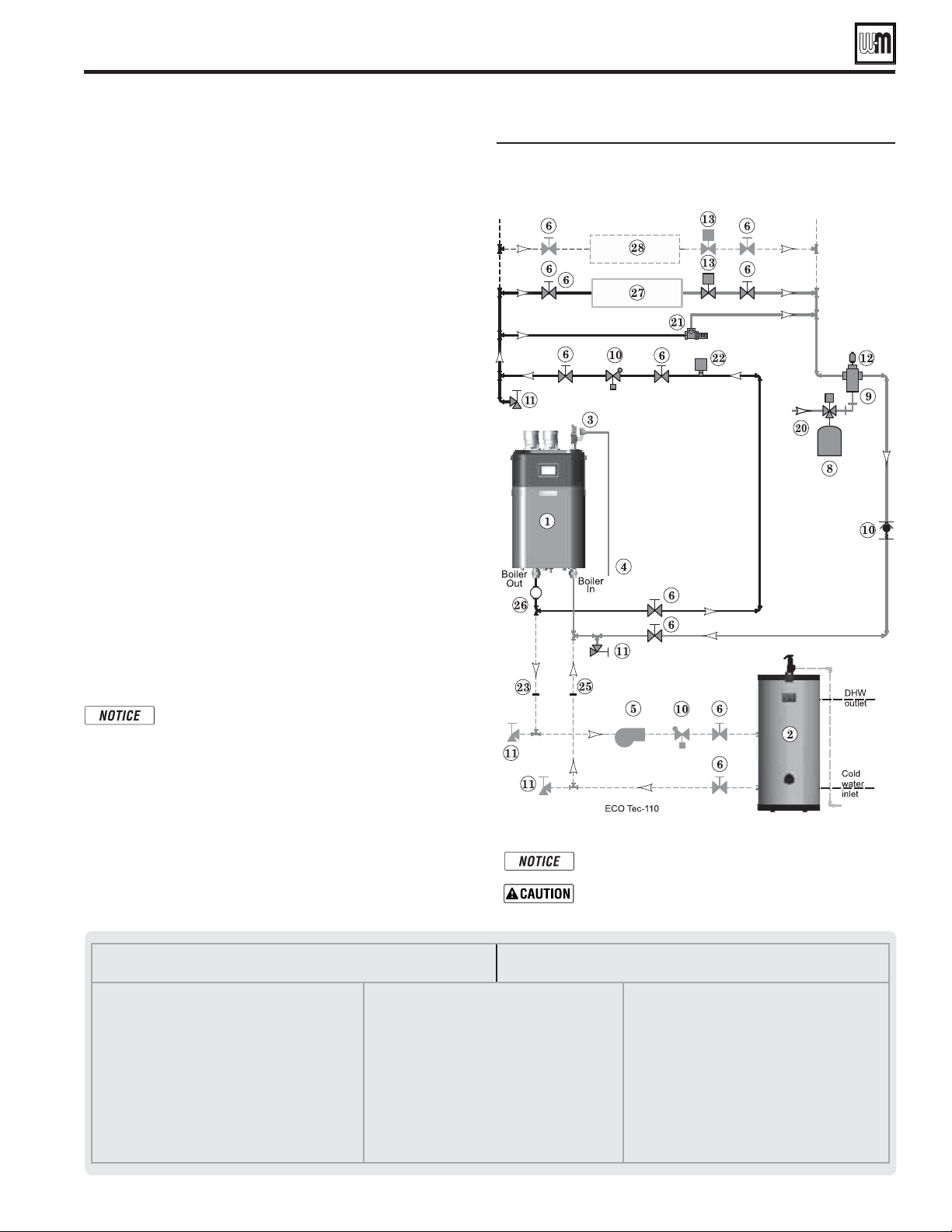

ECO

Tec 80/110/150 Zone valve zoning direct

connection (internal boiler circulator provides

flow for system

)

Part number 550-100-260/0520

49

ECO

®

Tec

GAS-FIRED WATER BOILER – 80/110/150/199 BOILER MANUAL

ZONE VALVE zoning – direct connection

(Shown with optional DHW piping)

See Figure59.

1. This configuration is for zone valve systems that qualify to

use direct connection piping based on the criteria on page 46

only. If system does not qualify, pipe using primary/secondary

piping. See pages 51-55 for piping suggestions and guidelines.

2. Systems zoned with zone valves MUST use a by-pass pressure

regulator (Taco 3196 or equivalent – Item 21) unless using

modulating type of circulator that has protection against

dead heading.

Expansion Tank required

1. Provide a system expansion tank following the guidelines on

page 46 or page 48.

2. DO NOT use a closed-type tank if connecting to a water

heater that is equipped with an automatic vent.

Domestic Hot Water (DHW) tank, if used

1.

DHW direct connection—Pipe from the near-boiler piping

to the DHW tank’s boiler connections as shown.

2. DHW as zone— A DHW tank can be connected as a zone

if a DHW tank is NOT already connected to the boiler. See

notices on page 149 to ensure compliance with the 2007

Energy Act. See Control section in this manual, page 84 to

change TARGET MODULATION SENSOR to System Supply

when system sensors are installed.

3. DHW Priority operation— Using Priority 1 for DHW

(default) will turn off lower priorities during DHW calls. The

MAX ON TIME setting can be adjusted to limit how long

this occurs. Use Priority 2 or 3 for DHW if DHW priority

is not desired.

Overriding the Outdoor Reset function by setting

control to DHW mode when system is intended

for space heating may violate Section 303 of the

2007 Energy Act. See page 149 for compliance

information and exemptions.

Controlling the circulators (Direct Connect only)

1. In a direct connect set-up, by default the internal circulator

will turn on for any configured heating call or DHW call.

2. If an Indirect tank is used, as in Figure 59, a secondary

circulator will have to be configured to turn on when the

indirect tank input is active.

Connect zone valve end switches to Priority 2 input.

Use isolation relays if connecting 3-wire zone valve end

switches to the input.

.

This is a common legend for all piping diagrams.

Not all Items listed appear in every figure.

1 ECO

Tec boiler

2 Indirect Water Heater, if used

3 Relief valve, supplied with boiler, field piped — MUST

be piped to Boiler In connection — see page 13 for

information

4 Relief valve piping to drain — see page 48

5 DHW circulator

6 Isolation valves

7 System circulator

8 Expansion tank, diaphragm type, if used

9 Air separator

10 Spring check valves

11 Purge/drain valves

(one drain valve shipped loose with boiler)

12 Auto air vent

13 Zone valves

14 Primary/secondary connection (tees no more than 12

inches apart)

15 Expansion tank, closed type, if used (some chiller

systems may use a diaphragm-type expansion tank)

16 Water chiller

17 Check valve

18 Y-strainer

19 Balancing valve

20 Make-up water supply – Use applicable codes to

determine if backflow preventers, pressure reducing

valves, and fill valves may be required

21 By-pass pressure regulator, REQUIRED for zone valve

systems unless other provision is made

22 High limit temperature control

23 DHW tank boiler water supply connection, when used

24 Zone circulator

25 DHW tank boiler water return connection, when used

26 Pressure/temperature gauge, supplied with boiler, field

piped

27 Heating circuits

28 Additional heating circuits, if any

Direct Connect System Piping - Single Boiler System (continued)

80/110/150 Boilers only

Loading ...

Loading ...

Loading ...