Loading ...

Loading ...

Loading ...

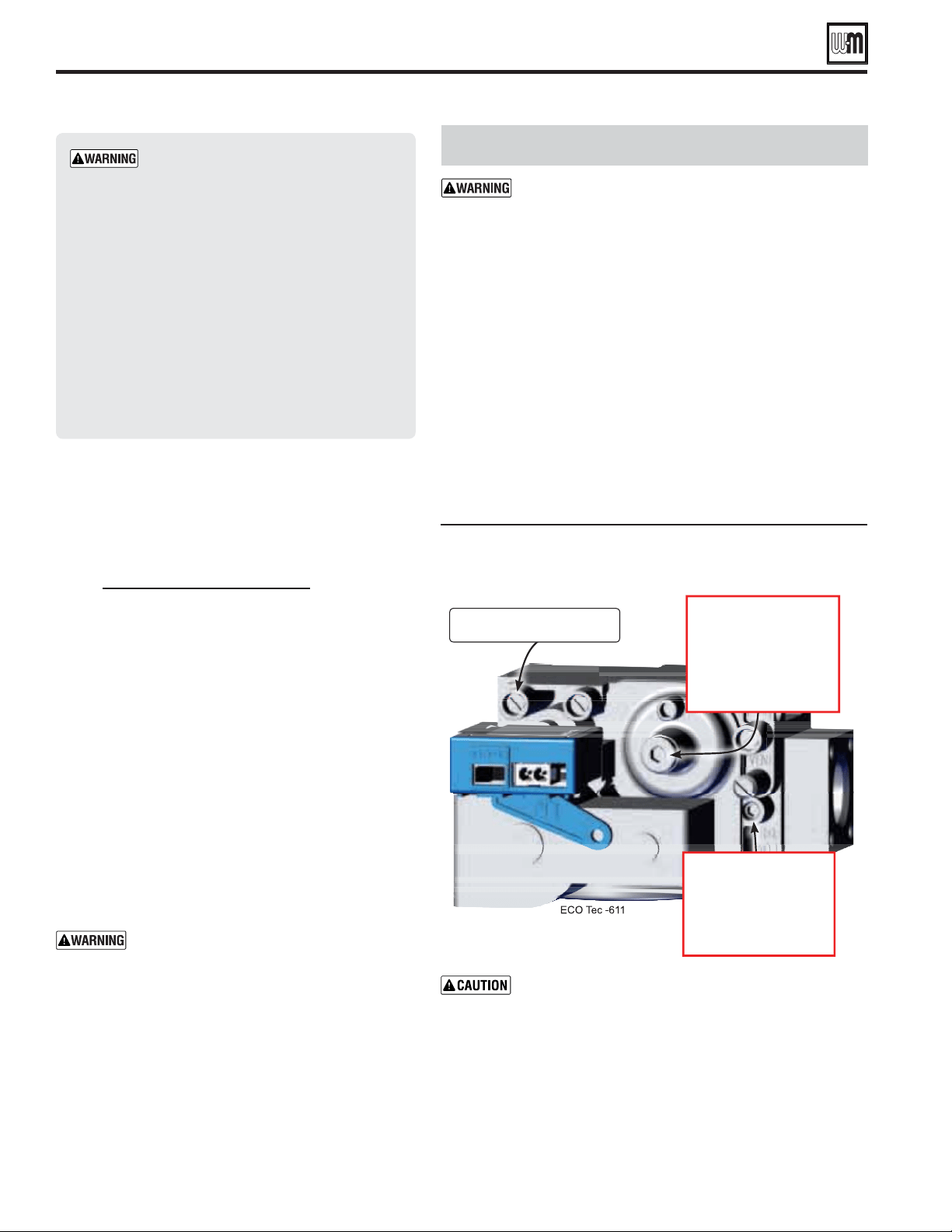

Throttle and Offset Regulating screw (ONLY for

use by a qualified technician, using calibrated

combustion test instruments)

Part number 550-100-260/0520

102

ECO

®

Tec

GAS-FIRED WATER BOILER – 80/110/150/199 BOILER MANUAL

Startup — fi nal checks (continued)

If combustion at either high or

low fi re is outside the range given

in Figure 95, page 105 , follow the

procedure given on this page or

page 105 for adjusting the gas valve.

If adjustment does not correct

the problem, then shut down the

boiler and contact your local Weil-

McLain representative. The gas valve

adjustment must be done only by a

qualifi ed technician, using calibrated

test instruments. Failure to comply

could result in severe personal injury,

death or substantial property damage.

7. Measure natural gas input:

a. Operate boiler 10 minutes. Turn off other appliances.

b. At natural gas meter, measure time (in seconds)

required to use one cubic foot of gas.

c. Calculate gas input:

3600 x 1000

= Btuh

number of seconds from step b

d. Btuh calculated should approximate input rating on

boiler rating label.

8. Use the control display to navigate to Manual test mode

(see Figure 89, page 95 ) and force the fi ring rate to LOW

(low fi re).

9. Look at the flame through the flame inspection

window. The low fi re fl ame should be stable and evenly

distributed over burner surface with a uniform orange

color.

10. Repeat the combustion test as instructed in the previous

steps.

11. Use the control display to navigate to Manual test mode

(see Figure 89, page 95 ) and force the fi ring rate to AUTO

(normal operation).

12. Reinstall the vent fl ue cap and ensure its sealed.

You must reinstall the vent fl ue cap to prevent

fl ue gas spillage into the boiler enclosure.

Failure to comply could result in severe

personal injury, death or substantial property

damage.

Gas Valve Adjustment

attempt to adjust the throttle or offset screw

unless done by a qualified technician, and with the

use of calibrated combustion test instruments. Adjust

the throttle or offset screw only as needed to meet

the combustion values given in Figure 94, page 103 .

Must confi rm correct low fi re RPM before making any

adjustments to Offset regulating screw.

1. Throttle screw adjustment is if specified

elsewhere in this manual or if combustion tests indicate the

need, as explained under “

,” page 100 .

2. Boiler behavior that might indicate a need to check combustion

values at high fi re (as per page 100 ) to verify boiler is in adjustment

include: difficulty igniting, poor flame stability at low fire,

combustion noise or high carbon monoxide values.

3. Combustion readings must be taken at both high fi re and low fi re.

DO NOT attempt an adjustment of the throttle screw at low fi re.

See Figure 93 for location of the throttle screw.

Adjust the throttle adjustment screw in small movements.

Make sure that the MAX RATE and MIN RATE for the PRIORITY that

you are planning on testing on are set to 100% and 10% respectively.

Then navigate to the MANUAL TEST MODE menu from the

DIAGNOSTICS menu ( Figure 89, page 95 ). After forcing the boiler to

HIGH FIRE insure the BLOWER SPEED has achieved the RPM listed on

Figures 98 or 99 ( Pages 110 or 111 ). Take CO

2

and CO readings and

adjust gas valve accordingly to Figures 93 and 94 allowing adequate time

for the combustion analyzer to stabilize.

Turn clockwise

to increase CO

2

. 3

Turn counter-clockwise to

decrease CO

2

. 4

Note: Must remove cover.

Throttle adjustment screw

Turn counter-clockwise

to increase CO

2

. 4

Turn clockwise to

decrease CO

2

. 3

Loading ...

Loading ...

Loading ...