Loading ...

Loading ...

Loading ...

12

IV. Information for Use with a Self-

Contained LP-Gas Supply System

D

O NOT STORE A SP

ARE LP GAS CYLINDER UNDER OR

N

E

AR THIS APPLIANCE.

NEVER FILL THE CYLINDER BEYOND 80% FULL. IF

THESE TWO STATEMENTS ARE NOT FOLLOWED

EXACTLY, A FIRE CAUSING DEATH OR SERIOUS

INJURY MAY OCCUR.

• If your oven is factory-built for LP (Propane)

the regulator supplied is set for 11" W.C. and is

for use with LP gas only. The factory-supplied

regulator and hose must be used with a 20 LB LP

cylinder.

• The LP-gas supply cylinder must be constructed

and marked in accordance with the Specifications

for LP-gas Cylinders of the U.S. Department of

Transportation (D.O.T.) or the National Standards

of Canada CAN/CSA-B339, Cylinders, Spheres

and Tubes for the Transportation of Dangerous

Goods, and Commission, as applicable; and

1. Provided with a listed overfilling prevention

device

2. Provided with a cylinder connection device

compatible with the connection for outdoor

cooking appliances

3. Marked with a 20 LB LPG capacity

It must be provided with a shut-off valve terminating

in gas tank valve outlet. It must include a collar

to protect the cylinder valve. The cylinder supply

system must be arranged for vapor withdrawal.

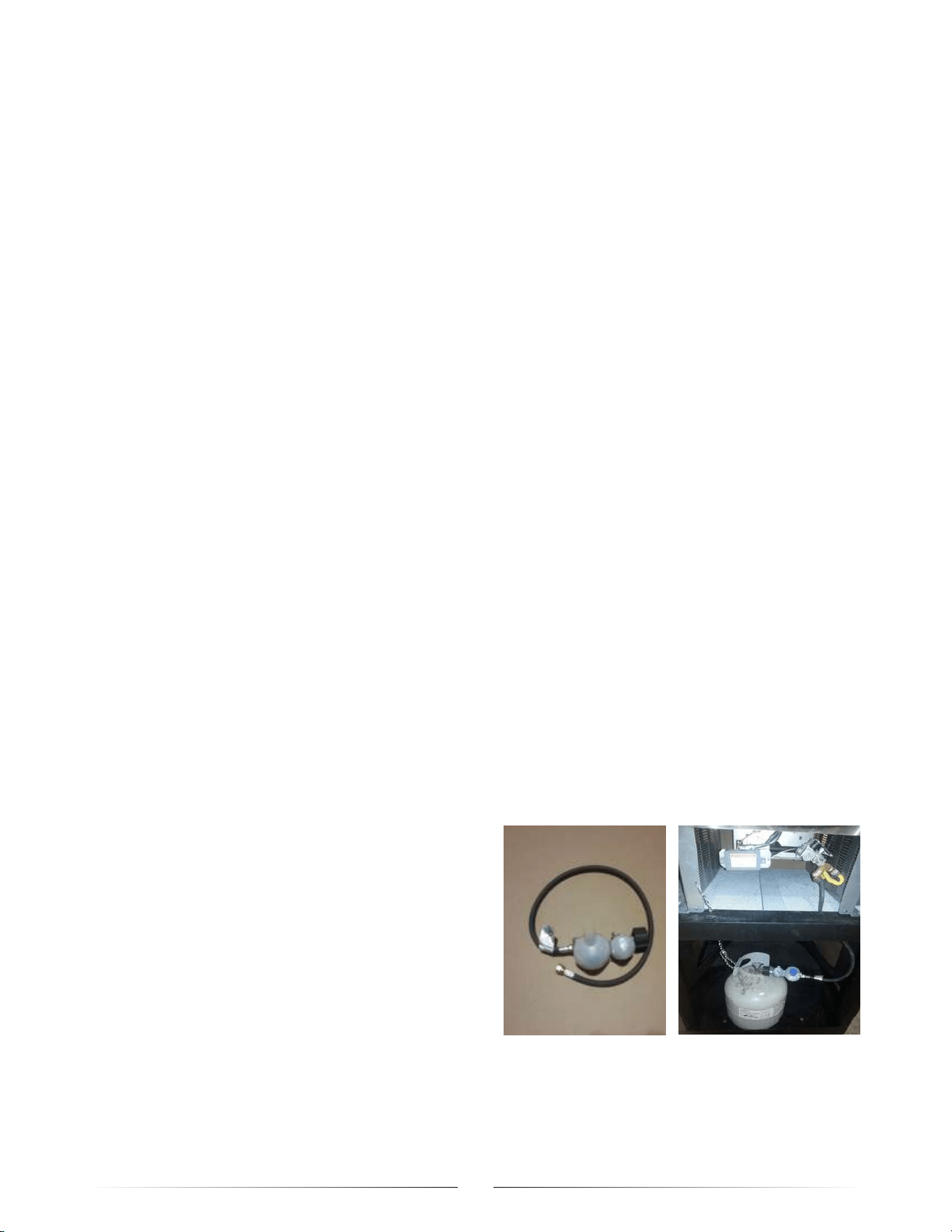

• Install the factory-supplied hose and regulator

assembly as shown in illustration. Connect the

3/8" flare end of the hose to the oven piping

outlet coupling using a ¾" open wrench. Do not

apply pipe sealant to the ¾" flare connection.

Gas/Electric Installation Continued

Locate and orient the LP cylinder to provide proper

vapor withdrawal. Connect the regulator to the

LP cylinder. Hand tighten it. Do not use a wrench.

Check for leaks using a leak detection solution.

NEVER USE OPEN FLAME TO CHECK FOR GAS

LEAK.

Note: Any 20 LB LPG cylinder can be used provided it

is compatible with the retention means as shown in

photo.

• If the oven is not in use, the gas must be turned

“OFF” at the supply cylinder. The cylinder must be

disconnected from the oven and stored outdoors,

out of the reach of children and must not be stored

in building, garage or any other enclosed area.

• Always inspect the hose before each use of the

oven. If it is evident there is excessive abrasion or

wear, or the hose is cut, it must be replaced prior to

the oven being put in operation. Replacement hose

assemblies will be specified by the manufacturer.

• The pressure regulator and hose assembly

supplied with to the oven must be used.

Replacement of pressure regulator and hose

assembly must be those specified by the oven

manufacturer. UL 21, Model 726 and 426, Rated

for 350 psi max work pressure.

Loading ...

Loading ...

Loading ...