Loading ...

Loading ...

Loading ...

BASIC SAW OPERATION

USING THE MITER GAUGE

CROSSCUTTING, MITER CUTTING, BEVEL CUTTING,

COMPOUND MITER CUTTING and when RABBETING

across the end of a narrow workpiece, THE MITER

GAUGE IS USED.

WARNING: FOR YOUR OWN SAFETY, ALWAYS

OBSERVE THE FOLLOWING SAFETY PRECAUTIONS

iN ADDITION TO THE SAFETY iNSTRUCTIONS ON

PAGES 2, 3, and 4.

1. Never make these cuts freehand (without using the

miter gauge or other auxiliary devices) because the

blade could bind in the cut and cause a KICKBACK or

cause your fingers or hand to slip into the blade.

2. Always lock the miter gauge securely when in use.

3. Remove rip fence from table.

4. Make sure blade guard is installed for all "thru-sawing'"

operations (when sawblade cuts entirely thru the

thickness of the workpiece.) Replace guard

IMMEDIATELY after completion of dadoing, molding

or rabbeting cuts.

5. Have blade extend approximately 1/8 in. above top of

workpiece. Additional blade exposure would increase

the hazard potential.

6. Do not stand directly in front of the blade in case of a

THROWBACK (Small cut-off piece caught by the back

of the blade and thrown toward the operator). Stand to

either side of the blade.

7. Keep your hands clear of the blade and out of the path

of the blade.

8,

9.

10.

11.

If blade stalls or stops while cutting, TURN SWITCH

OFF before attempting to free the blade.

Do not reach over or behind the blade to pull the

workpiece through the cut ... to support long or

heavy workpieces ... to remove cut-off pieces of

material or FOR ANY OTHER REASON.

Do not pick up small pieces of cut-off material from the

table. REMOVE them by pushing them OFF the table

with along stick. Otherwise they could be thrown back

at you by the rear of the blade.

Do not remove small pieces of cut-off material that may

become TRAPPED inside the blade guard while the saw

is RUNNING. THIS COULD ENDANGER YOUR

HANDS or cause a KICKBACK.

Turn the saw OFF. After the blade has stopped turning,

lift the guard and remove the piece.

WORK HELPERS

Before cutting any wood on your saw, study all of the

"Basic Saw Operations".

Notice that in order to make some of the cuts, it is

necessary to use certain devices "Work Helpers" like the

Push Stick, the Push Block and the Auxiliary Fence/Work

Support, which you can make yourself.

After you have made a few practice cuts, make up these

"helpers" before starting any projects. Make the "Push

Stick" first. To rip the piece for the push stick, start out

with a wide board, say 11-1/2 in, wide and set the rip fence

93/4 in. from the blade.

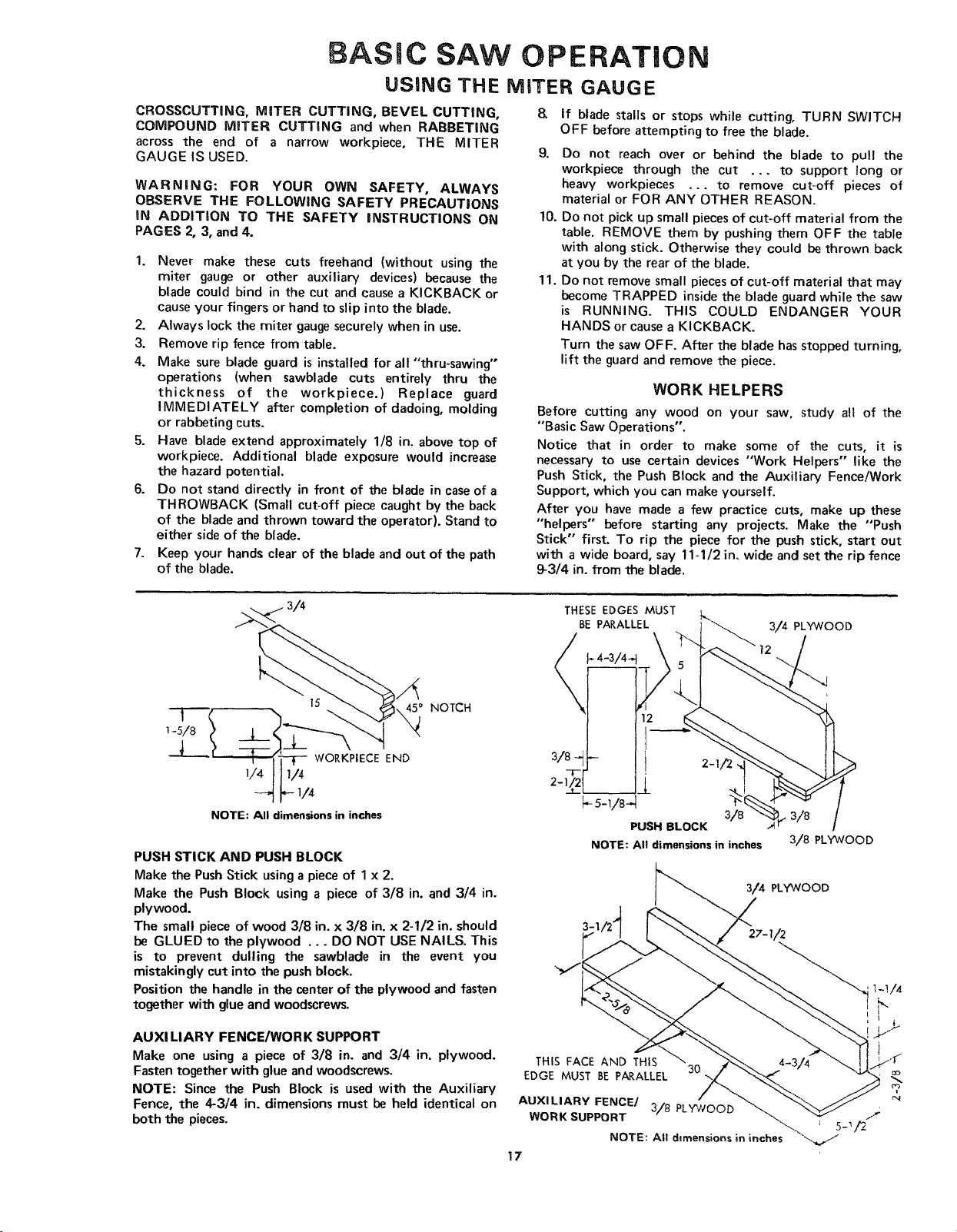

15

450 NOTCH

WORKPIECE END

1/4 I14

1/4

NOTE: All dimensions in inches

PUSH STICK AND PUSH BLOCK

Make the PushStick usinga piece of 1x 2.

Make the Push Block using a piece of 3/8 in. and 3/4 in.

plywood.

The small piece of wood 3/8 in. x 3/8 in. x 2-1/2 in. should

be GLUED to the plywood ... DO NOT USE NAILS. This

is to prevent dulling the sawblade in the event you

mistakingly cut into the push block.

Position the handle in the center of the plywood and fasten

together with glue and woodscrews.

AUXI LIARY FENCE/WORK SUPPORT

Make one using a piece of 3/8 in. and 3/4 in. plywood.

Fasten together with glueand woodscrews.

NOTE: Since the Push Block is used with the Auxiliary

Fence, the 4-3/4 in. dimensions must be held identical on

both the pieces.

THESE EDGES MUST

BE PARALLEL

_ 4-3/4

3/4 PLYWOOD

12

PUSH BLOCK

3/8

NOTE: All dimensions in inches

3/8

3/8 PLYWOOD

THIS FACE AND THIS

EDGE MUST BE PARALLEL 30

AUXILIARY FENCE/ 3/8 PLYWOOD

WORK SUPPORT

NOTE: All dimensions in inches

17

Loading ...

Loading ...

Loading ...