Loading ...

Loading ...

Loading ...

ENGLISH

10

indentations

8

to transport the saw as seen in FigureA and

Figure D.

Bench Mounting (Fig. A)

Holes

3

are provided in all 4 feet to facilitate bench

mounting, as shown in FigureA. Always mount your

saw firmly to a stable surface to prevent movement. To

enhance the tool’s portability, it can be mounted to a piece

of 1/2" (12.7 mm) or thicker plywood which can then be

clamped to your work support or moved to other job sites

andreclamped.

NOTE: If you elect to mount your saw to a piece of plywood,

make sure that the mounting screws don’t protrude from

the bottom of the wood. The plywood must sit flush on the

work support. When clamping the saw to any work surface,

clamp only on the clamping bosses where the mounting

screw holes are located. Clamping at any other point will

interfere with the proper operation of thesaw.

CAUTION: To prevent binding and inaccuracy, be

sure the mounting surface is not warped or otherwise

uneven. If the saw rocks on the surface, place a thin

piece of material under one saw foot until the saw sits

firmly on the mountingsurface.

COMPONENTS (FIG. A)

WARNING: Never modify the power tool or any part

of it. Damage or personal injury couldresult.

Intended Use

This heavy duty miter saw is designed for professional wood

cuttingapplications.

DO NOT use under wet conditions or in presence of

flammable liquids orgases.

DO NOT let children come into contact with the tool.

Supervision is required when inexperienced operators use

thistool.

Changing or Installing a New Saw Blade

(Fig. E–G)

Refer to Saw Blades under Optional Accessories for correct

sawblade.

WARNING: To reduce the risk of serious personal

injury, turn tool off and remove the battery pack

before transporting, making any adjustments or

removing/installing attachments or accessories.

An accidental start-up can causeinjury.

CAUTION:

• Never depress the spindle lock button

25

while

the blade is under power orcoasting.

• Do not cut metal, masonry or fiber cement

product with this mitersaw.

Removing the Blade (Fig. A, E–G)

1. Remove battery pack

13

from thesaw.

2. Raise the arm to the upper position and raise the lower

guard

4

as far aspossible.

3. Loosen, but do not remove the guard bracket rear

screw

21

by fourrevolutions. The bracket

23

can be

Limits to Bevel Angle

Maximum Miter

Angle

Max Bevel Angle at Which Cut Can Be

Completed

48° Left Side Left Bevel: 40°

48° Right Side Left Bevel: 42.5°

Limits to Miter Angle

AT Maximum Bevel

Angle

Max Miter Angle at Which Cut Can Be

Completed

48° Left Side

Left Miter: 31.6°

Right Miter: 35°

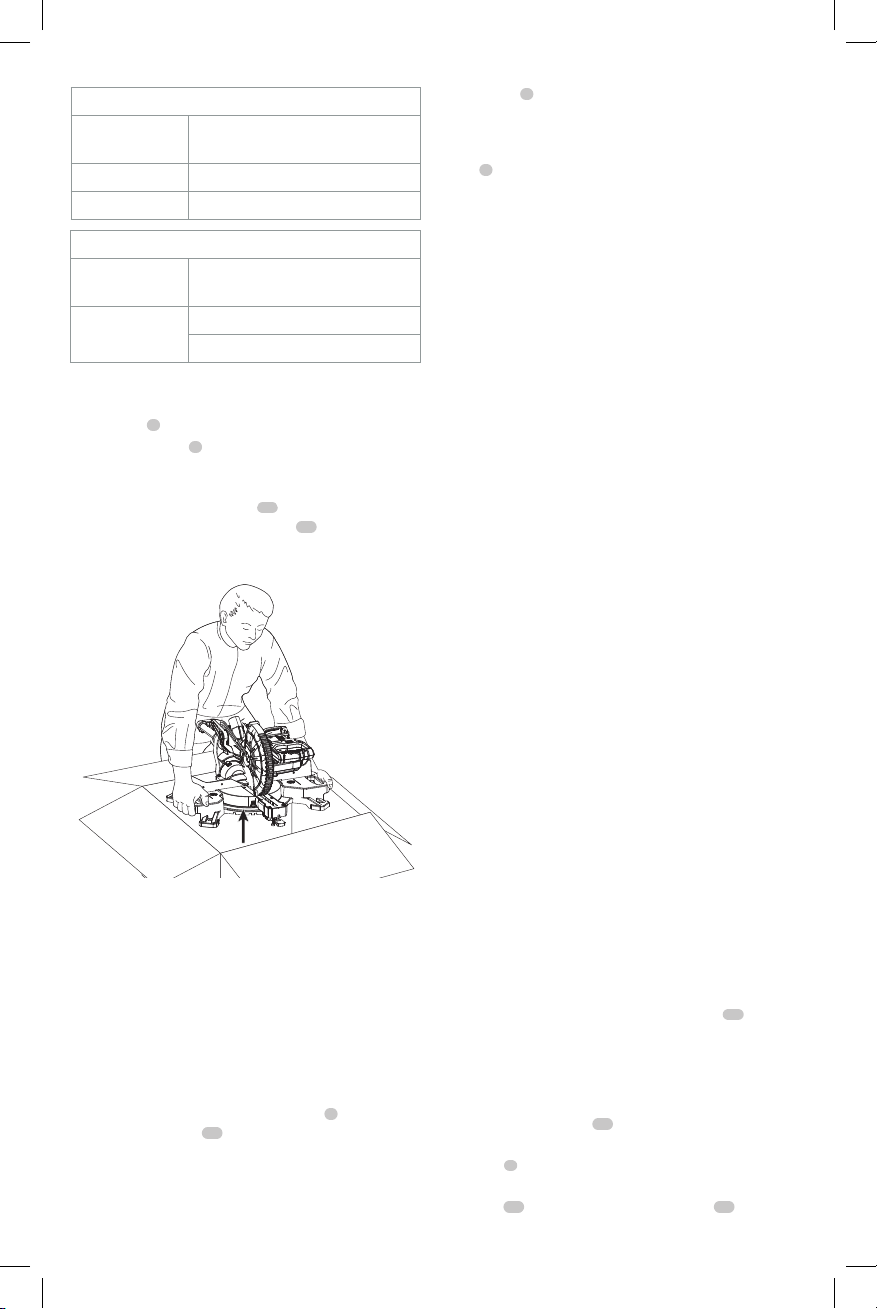

Familiarization (Fig. A, D, L)

Open the box and lift the saw out by using the hand

indentations

8

in the base of the saw (Fig.D).

The miter lock knob

5

is not assembled for shipping.

Remove the miter lock knob from the packaging and screw

onto the saw. Refer to Figure A for position.

You saw has a built-in dust port

12

that allows either the

supplied, but not assembled, dust bag

42

or shop vacuum

system to be connected. Refer to Dust Extraction for

assembly instructions.

Fig. D

Place the saw on a smooth, flat surface such as a workbench

or strongtable.

Examine FigureA to become familiar with the saw and its

various parts. The section on adjustments will refer to these

terms and you must know what and where the partsare.

CAUTION: Pinch hazard. To reduce the risk of injury,

keep thumb underneath the operating handle when

pulling the handle down. The lower guard will move

up as the operating handle is pulled down, which

could cause pinching. The operating handle is placed

close to the guard for specialcuts.

Press down lightly on the operating handle

2

and pull

out the lock down pin

19

. Gently release the downward

pressure and hold the operating handle, allowing it to rise

to its full height. Use the lock down pin when carrying

the saw from one place to another. Always use the hand

Loading ...

Loading ...

Loading ...