Loading ...

Loading ...

Loading ...

6

Pre-Installation

5.2 Siting Considerations

When choosing a suitable location for the cylinder

the following aspects should be considered:

- structural integrity

- access for installation, operation, maintenance

and replacement

- routing of discharge pipe work

- access to water mains supply, hot and cold

water distribution pipes

- access to suitable electricity supply

- location in relation to remaining system

components

- frost protection

The Quantum direct electric cylinders are

designedtobeoorstanding,verticallymounted,

indoors and in a frost free environment. The

cylindermaybelocatedonanyatandlevel

surface,provideditissufcientlyrobustto

support the weight of the cylinder when full of

water (please see technical data) and suitably

accessible for replacement/maintenance without

specialist tools or lifting equipment as this will

void the warranty conditions.

The position and orientation of the cylinder should

be such that easy access is provided for servicing

the controls. A minimum distance of 400mm in

front of the immersion is recommended, to allow

the replacement of the immersion heater should

the need arise. When installing the cylinder all

labels should be clearly visible and ensure that no

pipework hinders any work to be carried out on

the various cylinder components.

Particular care must be taken when placing the

cylinder in a garage or outbuilding. All exposed

pipe work must be correctly insulated to avoid

frost damage.

5.3 Cold Water Supply

For satisfactory and safe performance of the

unvented cylinder the water supply must meet the

following criteria:

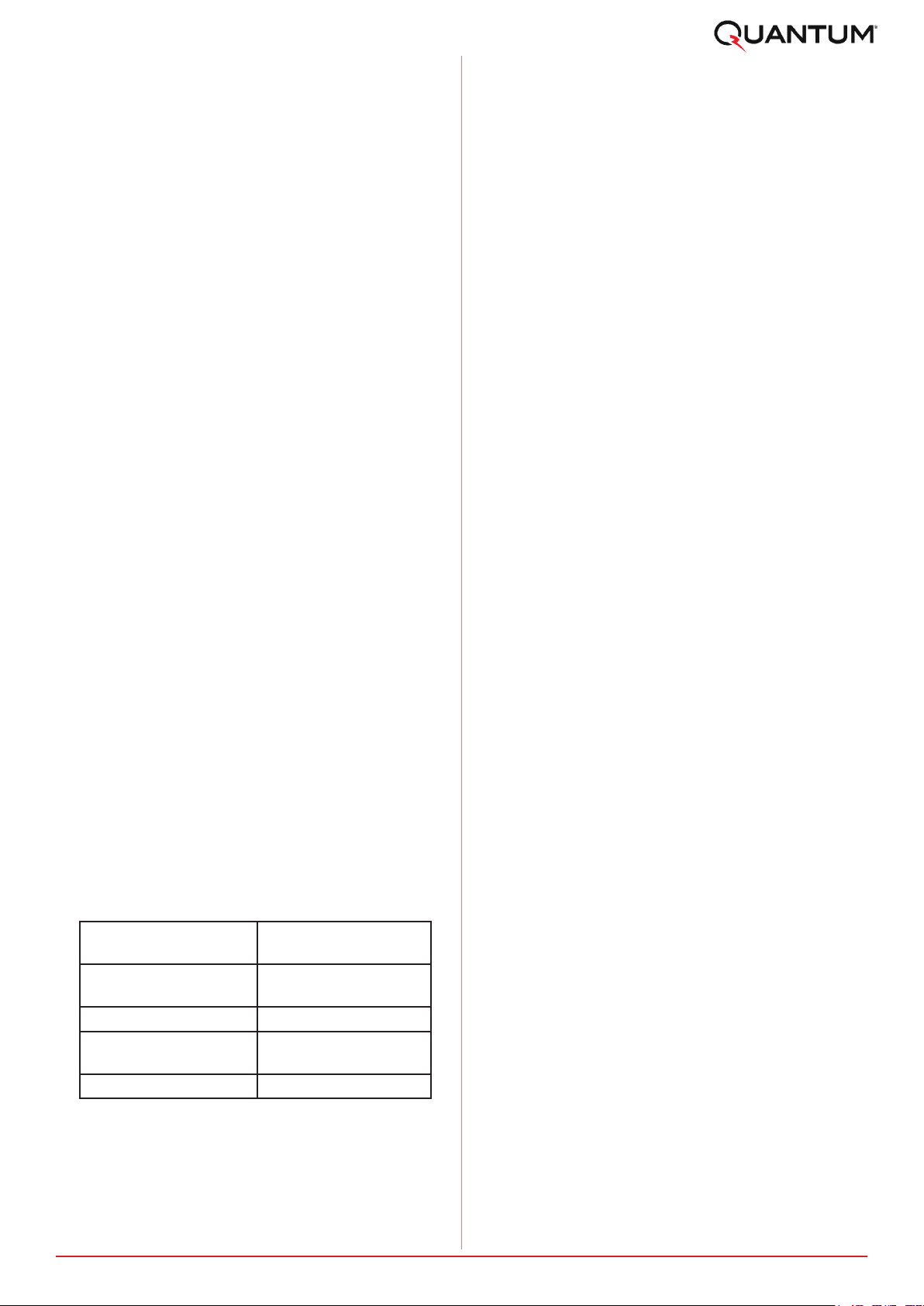

Minimum dynamic

pressure

150 kPa (1.5 bar)

Maximum inlet

supply pressure

1200 kPa (12 bar)

Minimumowrate 15 l/min

Max. chlorine

content

250mg/L

Max. water hardness 200mg/L

The following instructions have to be followed

when installing the cold water mains supply to the

cylinder:

- The cold water supply to the cylinder must come

directly from the cold water mains after the

mains stop valve to the property.

- The cold water inlet pipe work should have at

least an inside diameter of 19mm and should

meet the requirements of the water regulations

for the supply of wholesome water.

We recommend an annual maintenance inspection

is carried out on the domestic hot water cylinder.

In hard water areas this should include inspec-

tion of the immersion heater, [above 120ppm

or 120mg/l]. A local water treatment company

should be able to offer free water quality testing.

The heating

elements may require periodic de-scaling. The

installer should do this as part of a maintenance

agreement.

If required, precautions can be taken to minimise

effects of water hardness, i.e. installation of a

water conditioner or water softener. These devic-

es should be installed in hard water areas where

high water storage temperatures are required, i.e.

greater than 60°C storage temperatures, par-

ticularly when water hardness exceeds 200ppm.

Should the water cylinder require de-scaling, this

mustbeperformedbyaqualiedtechnician.

5.4 Building Regulation G3 Discharge

Requirements

As part of the requirements of Building

Regulation G3 any discharge from an unvented

system should be conveyed to where it is visible,

but will not cause danger to persons in or about

the building. The tundish and the discharge pipes

shouldbettedinaccordancewiththe

requirements of Building Regulation approved

document G3, (England and Wales), Part P of

Northern Ireland and Standard 4.9 of Scotland.

5.4.1 Discharge Pipe D2

According to the Building Regulations the

discharge pipe (D2) from the Tundish should:

“have a vertical section of pipe at least 300mm

long below the tundish before any elbows or

bends in the pipework and be installed with a

continuous fall of at least 1 in 200 thereafter.”

The discharge pipe (D2) should be made of:

“metal; or other material that has been

demonstrated to be capable of safely withstanding

temperatures of the water discharged and is

clearly and permanently marked to identify the

product and performance standard”.

Loading ...

Loading ...

Loading ...