Loading ...

Loading ...

Loading ...

15

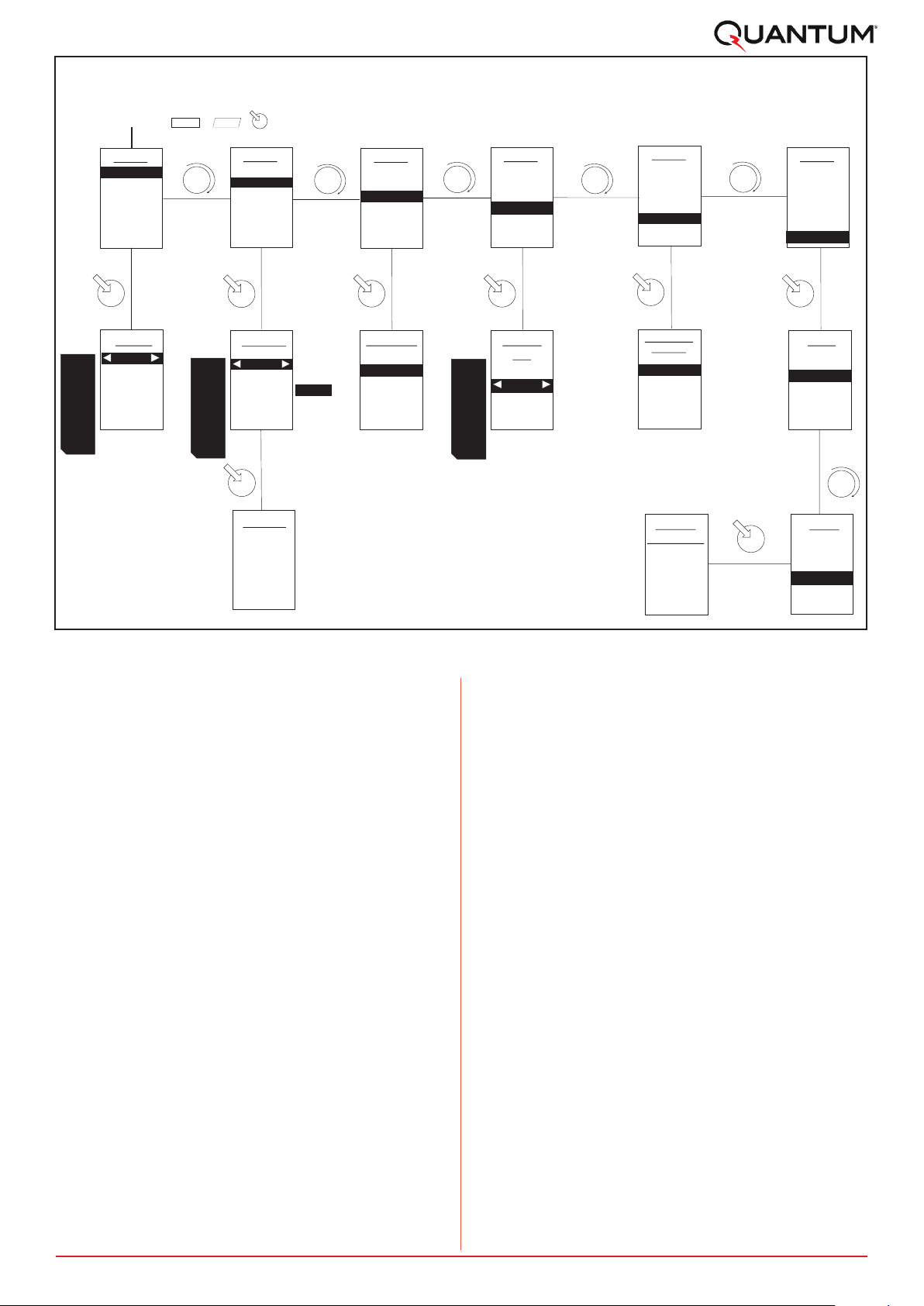

Maintenance

Hygiene

-

+

Daily

60°C

Daily/Weekly/Monthly/

OFF

60 … 65

-

+

Reset

Temp

Temp/Counter/

Energy/Factory

-

+

-

+

RF Module

0504030201

Disable

Enable

Push knob and

hold for 5 seconds

to reset

-

+

Service

Reset

Hygiene

RF Module

Cylinder

Tariff

-

+

-

+

-

+

Cylinder

Size

125

125/135 Slim/150

180 Slim/210/250/300

-

+

Tariff

Off Peak

Timed

-

+

Tariff

Off Peak

Timed

Off Peak

Time Period

ON 23:00

OFF 07:00

-

+

RTC Calibrate

Service

Reset

Hygiene

RF Module

Cylinder

Tariff

RTC Calibrate

Service

Reset

Hygiene

RF Module

Cylinder

Tariff

RTC Calibrate

Service

Reset

Hygiene

RF Module

Cylinder

Tariff

RTC Calibrate

Service

Reset

Hygiene

RF Module

Cylinder

Tariff

RTC Calibrate

Service

Reset

Hygiene

RF Module

Cylinder

Tariff

RTC Calibrate

-

+

Calibrate RTC

Oscillator

Cal Byte: 05

No

Yes

-

+

-

+

Selected

Hygiene

Daily

60°C

Menu

Menu

Back

Back

-

+

&

&

10s

Figure 12: Service Menu for Factory Reset and Communications Set Up

8 Maintenance

After servicing, complete the relevant Service

Record section of the Benchmark Checklist

located on the inside back pages of this

document. To meet with warranty requirements

the cylinder must be serviced annually.

The maintenance of this appliance must be car-

riedoutbyasuitablyqualiedpersononly.Itis

recommended to maintain the unit on an annual

basis. Isolate all

electrical supplies from the unit before

commencing work.

1) Draw some water from cold water tap and

retain in container.

2) Isolate cold water mains supply from

cylinder.

3) Brieyopentemperatureandpressure

relief valve, assure safe discharge and

check that valve is not dripping when

closed.

4) Brieyopenexpansionreliefvalve,assure

safe discharge and check that valve is not

dripping when closed. The expansion relief

valve should be operated regularly to

remove lime deposits and to verify that it

is not blocked.

5) Open hot water tap and release remaining

pressure from unit.

6) If the system is drained completely for

an internal inspection, ensure the hot

water tap remains open, connect a hose to

the drain valve and ensure a safe

discharge.

7) Note the set pressure of the pressure

reducing valve. Remove cartridge and

clean strainer in water provided in

container. Re-assemble pressure reducing

valve ensuring the correct pressure is set.

8) Periodically the immersion heaters should

beremovedcleanedandtheunitushed

out. Check the O-ring seal for damage and

replace if necessary.

9) Check electrical wiring connections and the

condition of the cable of the immersion

heater and the thermostat.

10) The immersion heater boss can also be

used for access to view the internal

components of the cylinder.

11) Re-commission unit (see chapter 7).

Loading ...

Loading ...

Loading ...