Loading ...

Loading ...

Loading ...

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 13

Both circuits will need to be protected with

appropriate breakers or fuse (see table below

giving the amperage drawn by the boiler on each

breaker) in conformity with local electrical codes.

Connections are made directly on the two

breakers inside the boiler.

These breakers can receive copper or aluminum

cable up to #1AWG..

The boiler can then be operated at approximately

50% of its nominal capacity when the breaker

supplying the electric circuit connected to breaker

#2 is turned OFF during periods of low demand.

Model

Modèle

AMPERE @ 208/240 VAC/1ph

Breaker #1

Breaker #2

33

2 x 5 KW, 1 x 6 KW

2 x 6 KW, 1 x 5 KW

57/66 Amps

61/70 Amps

36

3 x 6 KW

3 x 6 KW

65/75 Amps

65/75 Amps

Alternative #2: No 120Vac electrical supply

is required to serve external accessories

(pump is supplied by a separate circuit

outside the boiler)

The electrical supply is made the same way as

described in alternative #1 excepting that it does

not need the Neutral (N) conductor.

3.5.2 Electrical supply of External

accessories

When the boiler is supplied with a 120V circuit, the

total 120vac consumption of the boiler and

external accessories must not exceed 5A.

The maximum electrical consumption of 24vac

external accessories connected to R&C terminals

must not exceed 15VA.

3.5.3 Outdoor temperature sensor

If you want the boiler target temperature to

modulate according to the outdoor temperature

(when the outdoor temp. will get colder, the target

temp. will get higher). The supplied outdoor sensor

will have to be connected to S1 S1 before turning

the power on to the unit.

The installation of this sensor cancels the

operation of the boiler when the outdoor

temperature exceeds the selected value

corresponding to the maximum temperature

required for heating.

If you wish to operate the boiler at a fixed target

temperature, simply do not connect the sensor

before applying the power to the unit

The sensor shall be connected to terminals S1-S1

in the boiler using two 20 ga conductors.

Maximum length 100 ft. (33 m).

Do not put a jumper between S1&S1 if the outdoor

sensor is not used.

3.5.4 Connecting the thermostat and

pump.

Thermostat: Use a low voltage 24Vac thermostat

designed for central heating system (do not use a

240Vac thermostat designed for electric

baseboards).

Some thermostats are equipped with a

temperature sensor for radiant floor application.

The purpose of the thermostat is to give a signal to

the boiler that there is a demand for heat. When

the boiler will receive this signal, it will control the

activation of the heating elements.

A two stage thermostat could also be installed.

Then the second heating stage would be used to

activate the “Boost” program allowing the boiler

target to be gradually increased (see section

4.10).

Heating systems equipped with one thermostat

and one pump:

With an 18gauge cable, connect the room

thermostat directly to the following boiler terminals.

Two wire thermostat: Terminals “R” and “W”

Three wire thermostat: Terminals “C”, “R” and “W”

Using 14 gauge wires, connect the circulating

pump directly on terminals “P” and “P

N.B. The amperage of the pump and 120Vac

accessories must not exceed 5A or 1/6HP

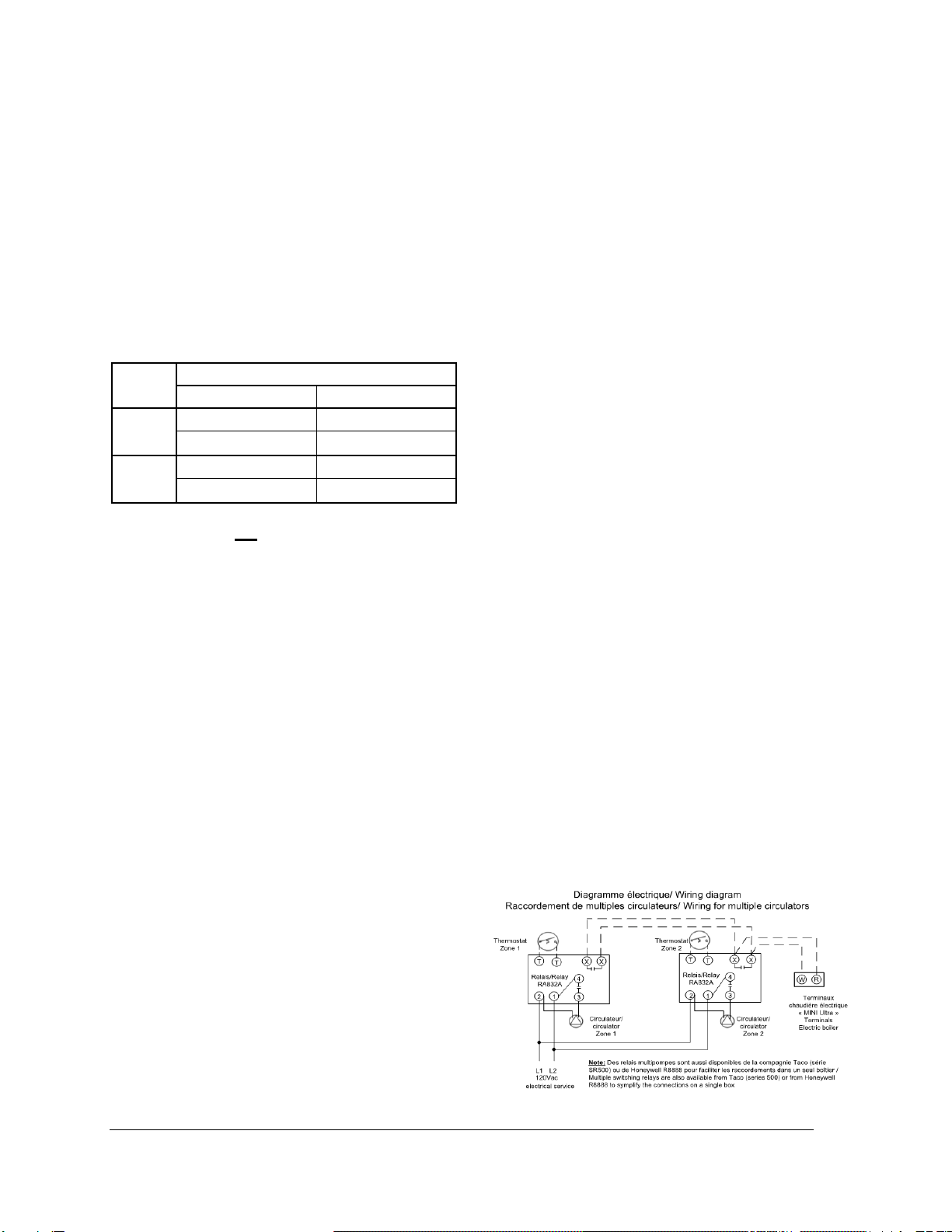

Zoning applications with multiple pumps

Components shall be connected in such a way

that when a thermostat is generating a heat

demand, only the corresponding pump be

operated and that this heat demand is brought to

the boiler in order to activate the elements.

To do so, you will need relays as illustrated below.

Boiler terminals P-P will not be used.

Figure 9 : Zoning with Multiple pumps

Loading ...

Loading ...

Loading ...