Loading ...

Loading ...

Loading ...

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 12

3.4.10 Dual Energy piping

Piping connections between the two boilers can be

made in parallel or in series as illustrated in fig.

7&8.

When installed in parallel, a three way motorized

valve (1”NPTF) is used to guide the heating

system return water toward the auxiliary boiler or

the BTH ULTRA electric boiler according to the

operating mode in demand. This way, the oil or

gas boiler is not maintained hot by the return water

when the operation is in Electricity.

N.B.: Make sure to select the appropriate port A, B

and AB when making the connection of the piping

(see fig.8)

3.5 ELECTRIC CONNECTIONS

3.5.1 Main Electric supply

Boiler wiring and grounding must conform to the

National Electrical Code and to state or local code

requirements. The latter having precedence.

Wire gauge must be properly sized by a qualified

electrician in such a way as to meet the national

electrical code.

To do so, consult the boiler rating plate which will

indicate the amperage drawn by the boiler at full

capacity. Extra amperage will have to be added if

external electrical equipment are connected to the

boiler.

This value and the electrical code will be used to

determine the electric cable required together with

the appropriate breaker.

Many other factors must be taken into

consideration in the selection of the appropriate

electrical material such as the length and the type

of cable used, the environment where the cable

will be installed and the type of the over-current

protection used.

Supply cables can be made of Aluminum or

Copper and be rated for a minimum of 75

o

C

(165

o

F).

If aluminum cables are used, it shall be of an

adequate size (generally bigger) and particular

consideration will have to be respected such as

the use of DE-OX inhibitors in order to meet the

National electrical code.

If the boiler electrical supply is on 208V, the

position of wire terminal on the transformer

connected to 240V will have to be changed to

208V.

The electrical supply can be done in two different

ways depending on the necessity of supplying or

not external accessories (such as a pump) at

120Vac.

Alternative #1: A 120VAC electrical supply

is required to serve external accessories.

Models 12 to 24 kW

Electrical wiring must come from a 120/240 Vac/or

120/208Vac -1ph “L1-N-L2-” circuit protected by a

properly sized breaker.

The main terminal block of the boiler is suitable for

#14 to #00 copper or aluminum wires rated for

75°C (165°F) min.

Models 27 & 29

1. The main electrical supply comes from two

electrical supply circuits

The electrical supply may come from two circuits

at 240V or 208V/1ph/60Hz with one of the circuit

having a neutral conductor.

The two circuits must be protected by a properly

sized breaker (see table below giving the

amperage drawn by the boiler on each terminal

block) in conformity with local electrical codes.

Connections are made on the two main terminal

block inside the boiler.

The boiler can then be operated at 50% of its

nominal capacity when the breaker supplying the

electric circuit connected to terminal block #2 is

turned OFF during periods of low demand.

These terminal blocks are suitable for #14 to #00

copper or aluminum wires rated for 75°C (165°F)

min.

2. The main electrical supply comes from one

electrical supply circuit)

The boiler electrical boiler supply could come from

only one circuit at 120/240 Vac or 120/208Vac

1ph/60Hz L1/N/L2 where the cable size will not

exceed AWG#00.

All the factory connected wires to terminal block

#2 will have to be transferred to terminal block #1.

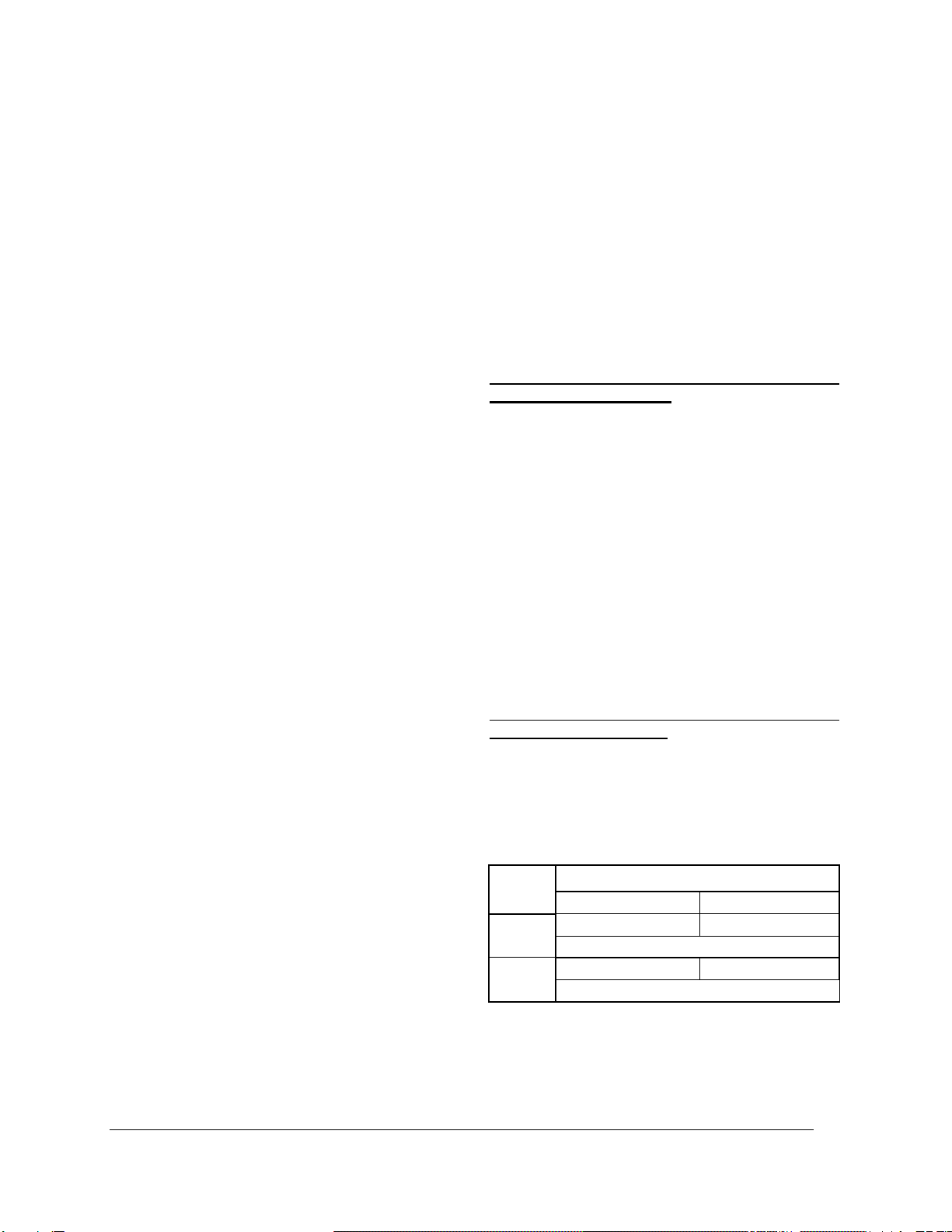

Models

AMPERE @ 208/240 VAC/1ph

Terminal Block #1

Terminal Block #2

27

49/56 Amps

49/56Amps

One terminal block 98/112A

29

52/60 Amps

52/60 Amps

One terminal block 104/120A

Models 33 & 36

The electrical supply must come from two different

electrical circuits. One circuit having three

conductors 120/240V or 120/208V “L1/N/L2” and

the other two conductors 240 or 208V “L1/L2”.

Loading ...

Loading ...

Loading ...