Loading ...

Loading ...

Loading ...

BTH ULTRA Electric Boilers Installation & Operation manual (Revision: June 2015) 11

3.4.2 Boiler piping connection

Make sure you connect the accessories and the

piping to the proper connection fittings as

indicated at figure 2 above and according to the

selected mounting position. The outlet and inlet

boiler connections are located on each sides.

They consist of 4 steel couplings (1”NPTF on 12 to

24kW models and 1-1/4”NPTF on 27 to 36kW)

where the piping connection will be made.

Local codes may dictate the type of pipe to be

used for the connections.

Install isolating valves to facilitate maintenance

3.4.3 Pressure relief valve

This component is supplied with the unit and must

be installed on the boiler. It is designed to

automatically open at approximately 30 psi.to the

appropriate connection according to the mounting

position.

Connect the outlet of the relief valve downward to

a safe location in case of discharge.

The piping diameter used for the discharge piping

shall not be smaller than that of the valve outlet.

No valve of any type, restriction or reducer

coupling should be installed on the discharge line.

Local codes shall govern the installation of relief

valves.

3.4.4 Expansion tank

The expansion tank must be able to store the

increase volume of boiler water occurring when

the boiler water increase in temperature.. The

maximum allowable operating pressure is 30 psi

(207 kPa). Contact your plumbing supply house

for assistance.

3.4.5 Water pressure regulator

The boiler should be installed in such a way that it

can automatically be fed with water in the event of

a pressure drop.

The minimum pressure obtained when the system

is cold is generally 12 psi (83 kPa).

This accessory shall be equipped with one or

more check valves to avoid all possibilities of the

boiler water returning to the potable water supply

network (local regulation should be applied)

3.4.6 Air eliminator

Installation of manual or automatic air vents are

required to eliminate all air from the boiler and the

heating distribution system.

The main air eliminator must be installed near the

outlet of the boiler on the highest point of the main

supply piping. It is imperative to insure that all air

possibly located in the boiler be eliminated at all

time.

3.4.7 Circulating pump

Water flow is required at all time when the boiler is

operating.

The pump shall be selected such as to be able to

supply adequate flow in relation to the heating

distribution system on which it will be connected

and the heating capacity of the boiler installed.

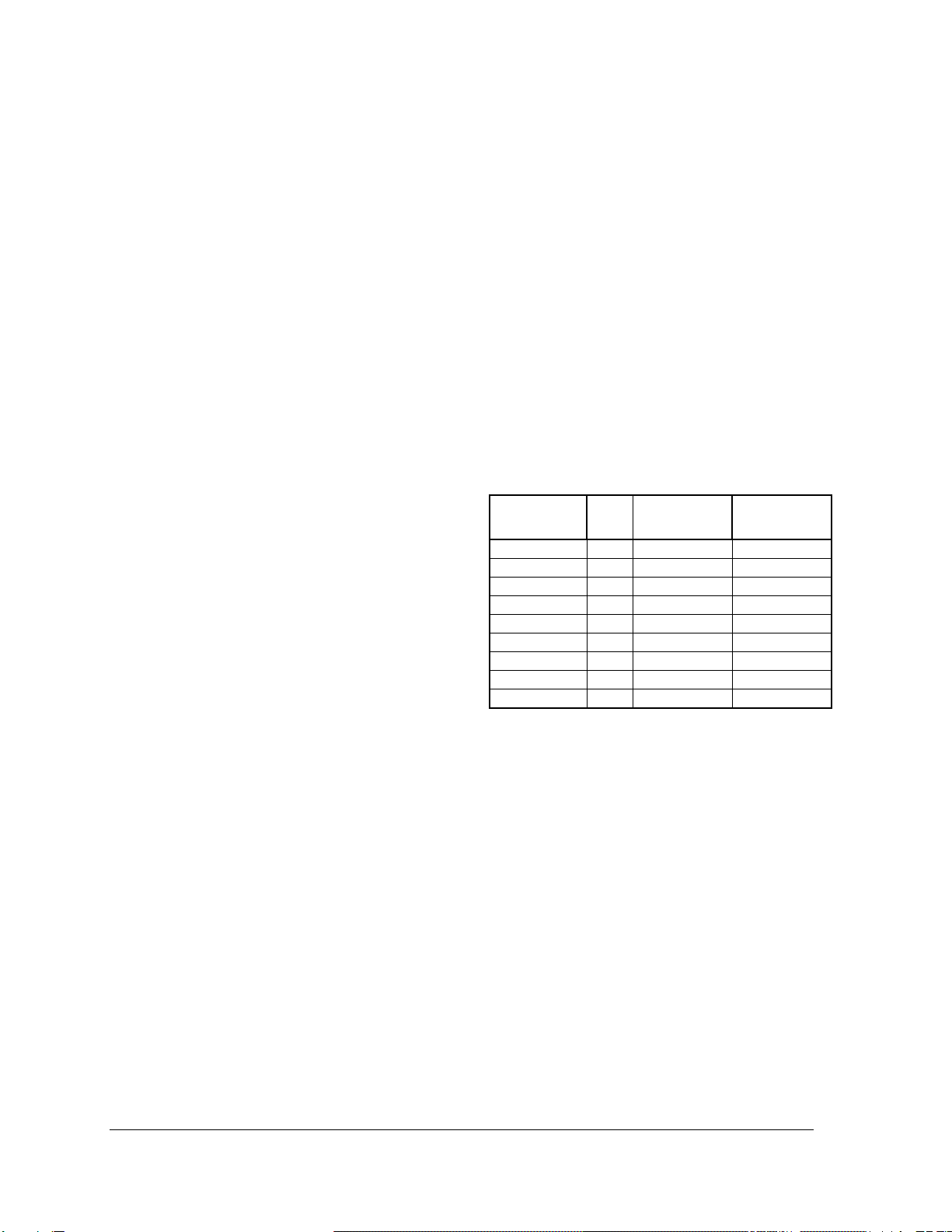

Table below shows required flow in relation to the

power capacity of the boiler and the required

temperature drop in the heating distribution

system. On System with baseboard heaters, 20°F

temperature drop is normally recommended and

on radiant floor application a value of 10°F is

generally used.

Table 5: Temperature rise vs flow rate

(GPM)

Model

KW

Diff. Temp.

Diff. Temp.

10

o

F

20

o

F

BTH ULTRA 12

12

8,2

4,1

BTH ULTRA 15

15

10,2

5,1

BTH ULTRA 18

18

12,3

6,1

BTH ULTRA 20

20

13,7

6,8

BTH ULTRA 24

24

16,4

8,2

BTH ULTRA 27

27

18,4

9,2

BTH ULTRA 29

29

20,5

10,2

BTH ULTRA 33

33

22,5

11,3

BTH ULTRA 36

36

24,7

12,3

Your heating wholesaler shall be in good position

to recommend the appropriate model for your

application.

If the pump is supplied by the PP terminals of the

boiler, its amperage plus the amperage drawn by

other 120V external components must not exceed

5A.

3.4.8 Drain valve

Installed at the lowest part of the unit, it allows the

boiler to be drained if defective components need

to be replaced.

3.4.9 Strainer

This component could be required on old heating

distribution systems made of steel or cast iron that

could carry sediments and sludge. If such

sediments accumulate at the bottom of the boiler it

could be harmful to the heat transfer of the

elements and generate premature failures.

Loading ...

Loading ...

Loading ...