Loading ...

Loading ...

Loading ...

Preparing to Start the Pump – Deep Well 11

For parts or assistance, call Simer Customer Service at 1-800-468-7867

Never run pump dry. Running pump without water may cause

pump to overheat, damaging seal and possibly causing burns to persons

handling pump. Fill pump with water before starting.

Never run pump against closed discharge. To do so can boil

water inside pump, causing hazardous pressure in unit, risk of explosion

and possibly scalding persons handling pump.

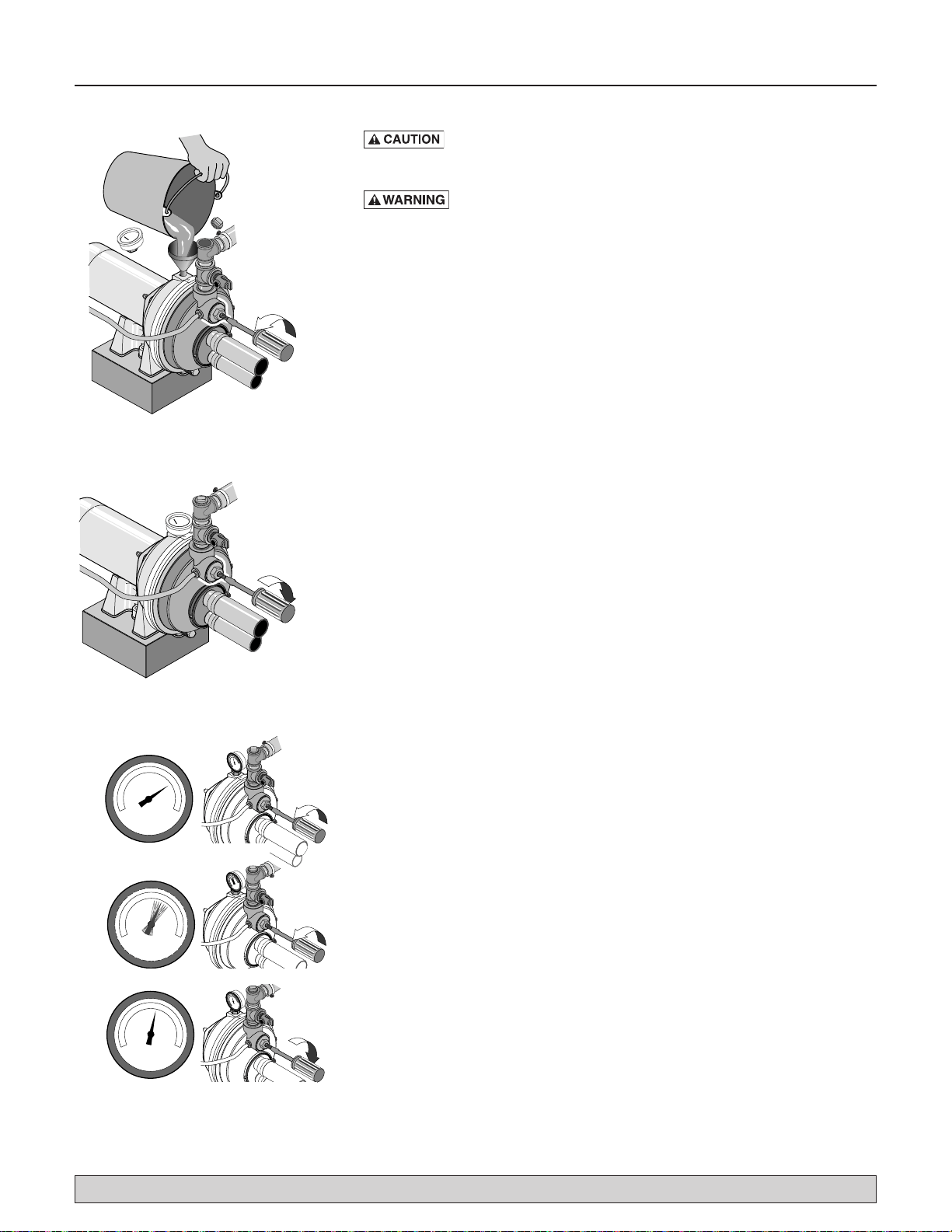

1. Open the control valve as far as possible (see Figure 16). Then remove

the priming plug from the pump and fill the pump, fill all piping

between the pump and the well, and make sure that all piping in

the well is full. If you have also installed a priming tee in the suction

piping, remove the plug from the tee and fill the suction piping.

2. Replace all fill plugs and close the control valve completely (Figure17).

3. Open several faucets in the residence to permit water flow and to

release trapped air. Power on! Start the pump and watch the pressure

gauge. The pressure should build rapidly to 50 PSI as the pump primes.

4. After 2 or 3 minutes, the gauge should show pressure. If not, stop the

pump, remove the fill plugs, reopen the control valve, and refill the

pump and piping. You may have to repeat this two or three times in

order to get all the trapped air out of the piping. Don’t forget to close

the control valve each time before you start the pump.

5. When water pressure has built up and is maintained by the pump,

slowly open the control valve (see Figure 18) – this will let water flow

to the residential piping. Slowly open the control valve while watching

the pressure gauge needle. Continue opening the valve until the valve

is fully open or you see the pressure gauge needle start to flutter. If the

needle starts to flutter, slowly close the valve just enough to stop the

flutter. Your pump is now operating at peakefficiency.

6. Close all open faucets. After the pump has built up pressure in the

system and shut off, check the pressure switch operation by opening a

faucet or two and running enough water out to bleed off pressure until

the pump starts. The pump should start when pressure drops to 30 PSI

and stop when pressure reaches 50 PSI. Run the pump through one

or two complete cycles to verify correct operation. This will also help

clean the system of dirt and scale dislodged during installation.

Congratulations on a successful installation.

If you were unsuccessful, please refer to Troubleshooting or call our

customer service technical staff.

Thank you for purchasing Simer Products.

P

Open control valve

as far as possible

and fill pump and

piping through

priming port

or priming tee.

Figure 17: Prime Pump

Figure 18: Set Control Valve

P

C-Close Control Valve until Pressure

Stabilizes

A-Open Control Valve

B-Watch for Pressure Gauge to Flutter

Figure 16: Fill Pump

Replace all

fill plugs and

close control

valve completely.

Loading ...

Loading ...

Loading ...