Loading ...

Loading ...

Loading ...

4

GAS CONNECTION

Gas installation must be made in accordance with AS5601;

Also refer to rangehood manufacturers recommendation.

Check gas presure, note the correct setting from the data

plate sealed inside the front appliance drawer *.

Installing the gas cooker :

(Flexible connection are NOT permitted with this

appliance)

-

An inlet manifold extension pipe must be fitted to the

appliance. Part supplied in the drawer of the appliance.

-

Ensure that the pipe is connetted using the washer

provided and that the braket is screwed to the appliance

as shown in the diagram below.

-

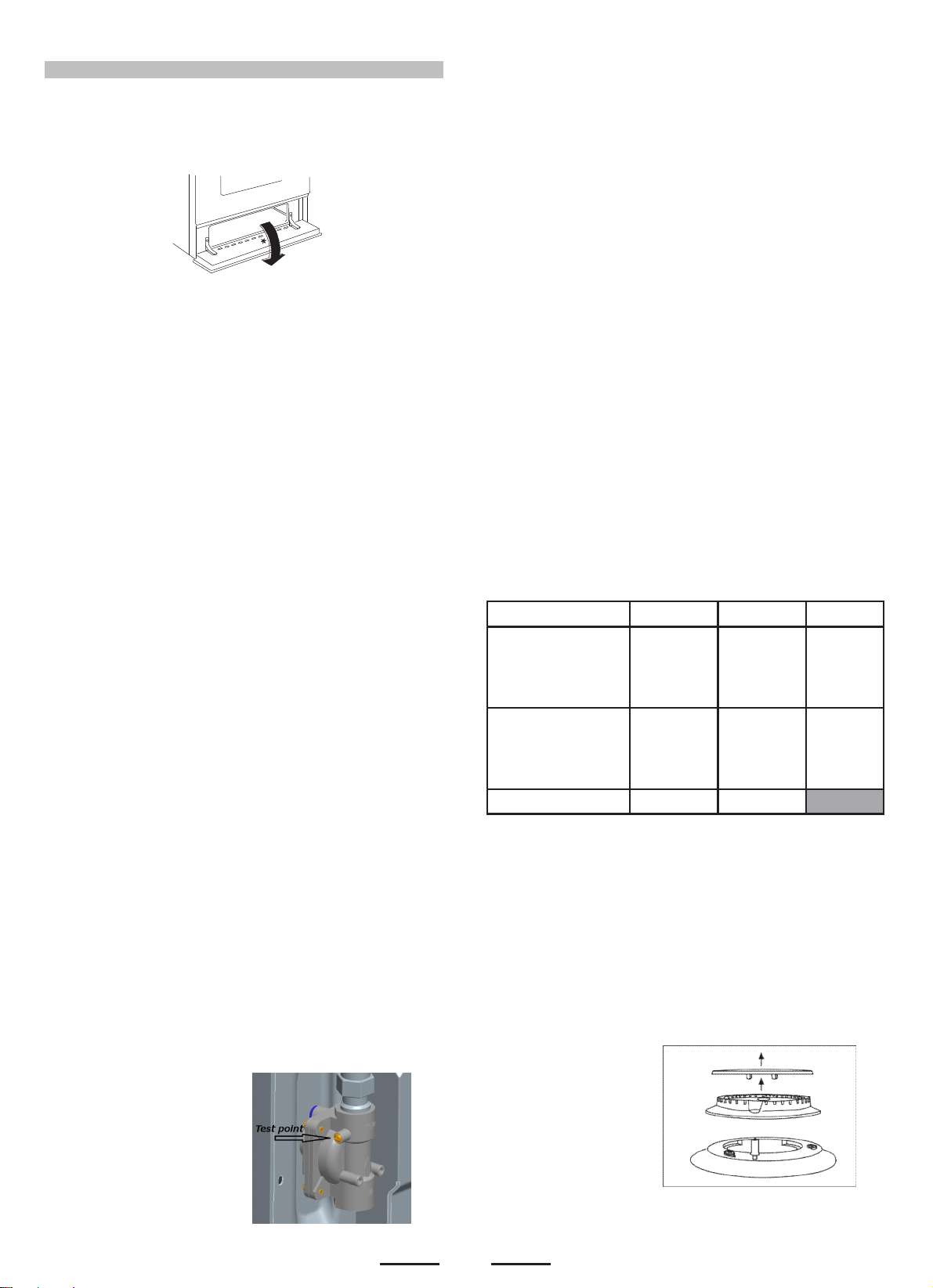

Fit the supplied pressure regulator ( for Natural gas )

using the NG test piont adaptor and washer to the inlet

manifold. Ensure the arrow is pointing towards the

appliance and that pressure testpoint is accessible from

the final position.

-

Push the cooker back and install the stabilizing chains.

-

Connect the appliance inlet manifold to the consumer

piping outlet using only fixed piping. This final connection

is made when the product is pushed back into position by

access under the cooker.

The hose assembly

- must comply whit ASINZS 1869 Class B or D,

- be of appropriate internal diameter and be kept

as short as possible ( less than 1,2 mm)

- It must not be kinked

- It must not be in contact whit hot surfaces

IT IS RECOMMENDED THAT A SERVICE TAP AND UNION

BE

FITTED ADJACENT TO THE APPLIANCE INLET TO

FACILITATE

FUTURE SERVICING.

5 burner models: set the burner pressure to 1kPa for Natural Gas

and 2.75kPa for U-LPG with the wok burner operating a full rate'.

For commissioning of the appliance with the regulator for

Natural Gas, the test point pressure should be 1.00kPa with

all burners operating on HIGH.

Apply a manometer to the test nipple and reset the regulator if

necessary. Do not forget to replace the test nipple screw and to

leave the instructions book with the user.

For ULPG a test point fitting must be installed betweeen

the piping and the appliance for the pressureto be

checked to ensure it is operating at 2.75 lPa

Test point for Natural gas

VERY IMPORTANT FOR THE INSTALLER

Do not attempt to turn or stress threaded elbow of the manifold:

you risk damage to this part of the gas appliance which may void

the manufacturers warranty.

Before Leaving - Check all connections for gas leaks with soap

and water. DO NOT use a naked flame for detecting leaks. Ignite

all burners to ensure correct operation of gas valves, burners and

ignition. Turn gas taps to low flame position and observe stability

of the flame.

When satisfied with the cooker, please instruct the user on the

correct method of operation.

In case the appliance fails to operate correctly after all checks

have been carried out, refer to the authorised service provider in

your area.'

GAS CONVERSION AND ADJUSTMENT

When used with natural gas all burners have been preset at our

factory and further adjustment should not be necessary. Conversion

kits to other gases are available from the place of purchase. Do

not attempt to fit the conversion kit yourself. Conversion to U-LPG

gas should only be carried out by an authorized technician.

GAS ADJUSTEMENTS

-

change the injectors

-

adjust the minimum flow

'When converting from Natural Gas to U-LPG ensure that

the NG regulator is removed and replaced with the Test Point

Assembly. A gas regulator suitable for a supply pressure of 2.75kPa

should be part of the gas tank supply and should be adjusted with

the wok burner operating at maximum.

REPLACEMENT OF THE INJECTORS

When required to operate on other gas replace the injectors in

accordance with information referred to in chart below.

Tab. 1

Gas Type

kPa

Jet mm 0

Burners

Power MJ/h

Natural

1.00

1.20

Semirapid

7.1

0.90

Auxiliary

4.0

1.50

Rapid

11.0

1.63

Triple Crown

12.7

U-LPG

2.75

0.73

Semirapid

7.1

0.53

Auxiliary

3.7

0.95

Rapid

11.7

1.00

Triple Crown

13.0

Regulator

NG Regulator

LP

Test

point

adaptor

Adjustments, conversions and gas installations must only be carried

out by an authorised person.

After the replacement of the injectors , replace also the

label of the type of gas

SPECIAL NOTE

After installation or any servicing operation, always ensure that

the appliance is gas sound and that the components are now

operating correctly. Items removed during servicing should be

replaced in the reverse order to their removal.

In order to change the work-top injectors, it is necessary to act as

follows:

-

remove the grids

-

remove burners

and flame-spreaders.

Loading ...

Loading ...

Loading ...