Loading ...

Loading ...

Loading ...

14

Fig.

6

V

Fig.

7

D

V

7

Disassembly of the worktop must only be done by a qualified

service technician

DISASSEMBLE OF WORK-TOP

ln case it is necessary to repair or replace the inside components,

act as follows:

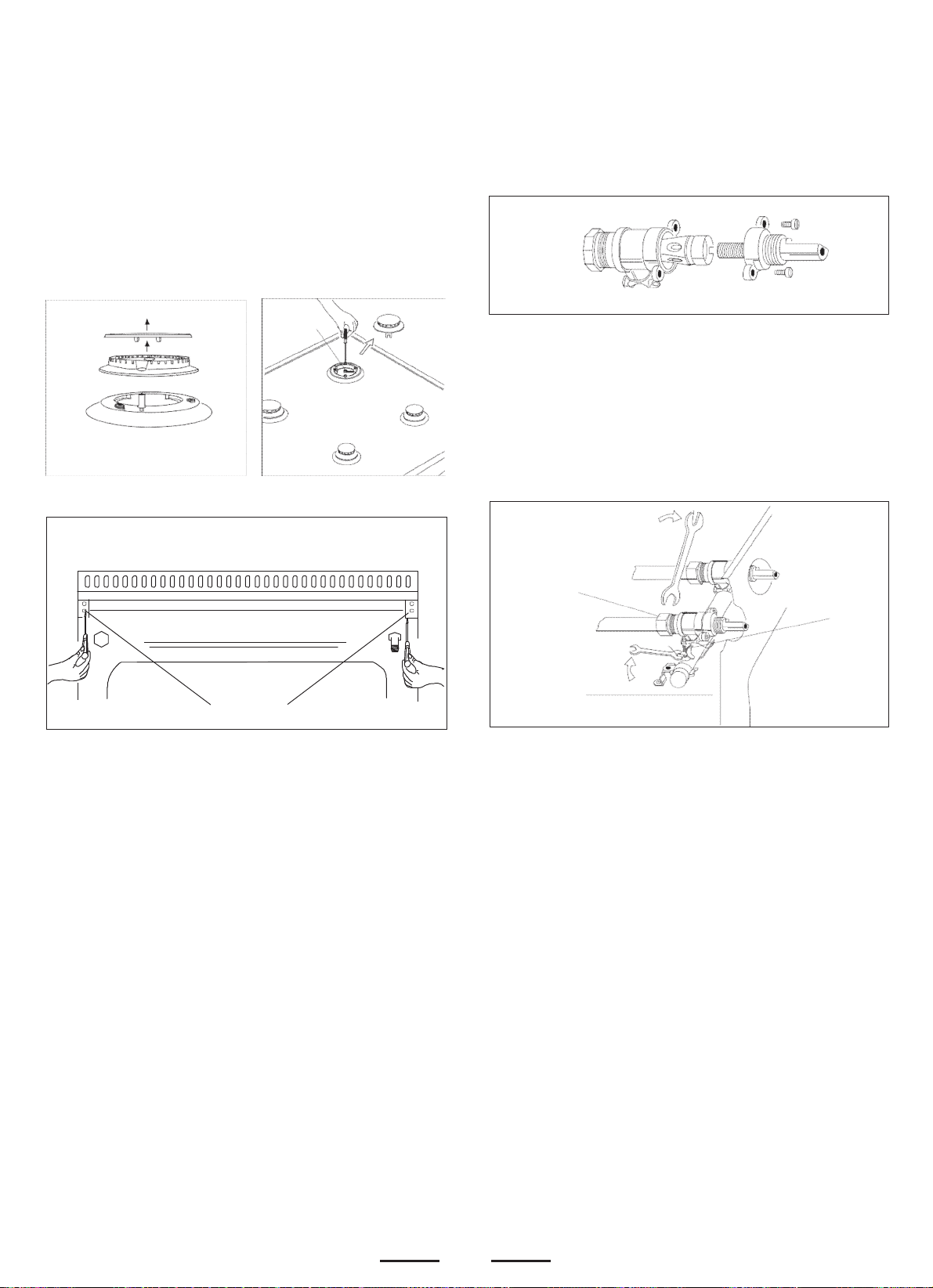

Remove the grids, remove burners and flame-spreaders (see

Fig. 6), unscrew the visible screws "V" placed on the work-top

(see Fig. 7). Disassemble the work-top by unscrewing the rear

screws "A" (see Fig. 15 according to the models). ln this

way it is possible to lift the work-top and to reach the inside

components.

GREASING OF TAPS

If a tap becomes hard to be turned, grease it using a specific

grease withstanding high temperatures. Act as follows: open the

work-top and disassemble also the control panel as described on

the previous paragraph. Unscrew the two fixing screws from the

burner body (see picture) and remove the cone.

TAPS REPLACEMENT

Act as follows: open the work-top and disassemble also the control

panel as described on the previous paragraph. Unscrew screw

nut D of the gas tube supplying the burner. Unscrew screw V

fixing the tap to the bridle and remove it (see picture).

Note: Every time the tap is replaced, it is necessary to replace

the seal gasket too check the connection seal by means of soapy

water.

Clean the cone and its slot by means of a cloth soaked with solvent.

Slightly grease the cone with the relevant grease, put it in its slot,

and turn it some times. Remove the cone again, remove the excess

grease making sure the gas entries are not obstructed by grease

residue. Assemble everything carefully in the opposite direction

check the connection seal by means of soapy water.

A

Fig. 8

Loading ...

Loading ...

Loading ...