Loading ...

Loading ...

Loading ...

En-5

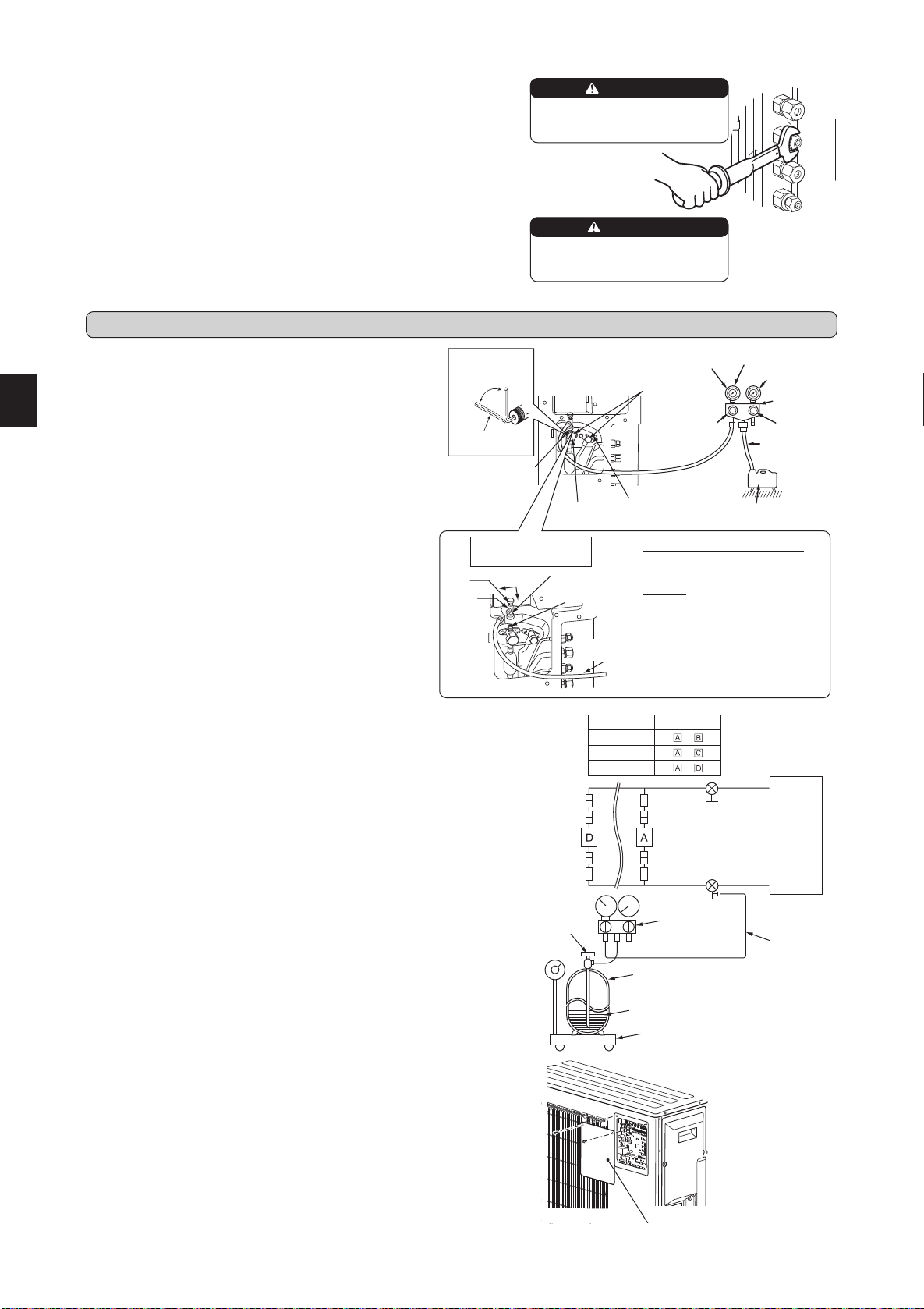

4-1. PURGING PROCEDURES AND LEAK TEST

4-2. GAS CHARGE

Performgaschargetounit.

1)Connectgascylindertotheserviceportofstopvalve.

2)Performairpurgeofthepipe(orhose)comingfromrefrigerantgascylinder.

3)Replenishspeciedamountoftherefrigerant,whileoperatingtheairconditioner

forcooling.

Note:

Incaseofaddingrefrigerant,complywiththequantityspeciedfortherefrigerat-

ingcycle.

CAUTION:

Whenchargingtherefrigerantsystemwithadditionalrefrigerant,besuretouseliquid

refrigerant.Addinggasrefrigerantmaychangethecompositionoftherefrigerantin

thesystemandaffectnormaloperationoftheairconditioner.Also,chargetheliquid

refrigerantslowly,otherwisethecompressorwillbelocked.

Tomaintainthehighpressureofthegascylinder,warmthegascylinderwithwarm

water(under40°C)duringcoldseason.Butneverusenakedreorsteam.

1)Removeserviceportcapofstopvalveonthesideoftheoutdoorunit

gaspipe.(Thestopvalvesarefullyclosedandcoveredincapsin

theirinitialstate.)

2)Connectgaugemanifoldvalveandvacuumpumptoserviceportof

stopvalveonthegaspipesideoftheoutdoorunit.

3)Runthevacuumpump.(Vacuumizeformorethan15minutes.)

4)Checkthevacuumwithgaugemanifoldvalve,thenclosegauge

manifoldvalve,andstopthevacuumpump.

5)Leaveasitisforoneortwominutes.Makesurethepointerofgauge

manifoldvalveremainsinthesameposition.Conrmthatpressure

gaugeshows-0.101MPa[Gauge](-760mmHg).

6)Removegaugemanifoldvalvequicklyfromserviceportofstopvalve.

7)

Fullyopenallstopvalvesonthegaspipeandtheliquidpipe.Operating

withoutfullyopeninglowerstheperformanceandthiscausestrouble.

8)Referto1-2.,andchargetheprescribedamountofrefrigerantif

needed.Besuretochargeslowlywithliquidrefrigerant.Otherwise,

compositionoftherefrigerantinthesystemmaybechangedand

affectperformanceoftheairconditioner.

9)Tightencapofserviceporttoobtaintheinitialstatus.

10

)Leaktest

Union

Stop valve

Liquid

pipe

Indoor

unit

Stop valve with

service port

Gas

pipe

Outdoor

unit

Union

Union

Union

Model Indoor unit

MXZ-2E

–

MXZ-3E

–

MXZ-4E

–

Refrigerantgas

cylinder

operatingvalve

(forR410A)

Gaugemanifold

valve(forR410A)

Chargehose

(forR410A)

RefrigerantgascylinderforR410Awithsiphon

Electronicscaleforrefrigerantcharging

Refrigerant(liquid)

Stopvalve

forGAS

Stopvalvecap

(Torque19.6to

29.4N•m,200

to300kgf•cm)

Gaugemanifold

valve(forR410A)

Compoundpressure

gauge(forR410A)

–0.101MPa

(–760mmHg)

Handle

Low

HandleHigh

Vacuumpump

(forR410A)

*Close

*Open

Hexagonalwrench

*4to5turns

Stopvalve

forLIQUID

Pressuregauge

(forR410A)

Precautionswhenus-

ingthecontrolvalve

Whenattachingthecontrolvalve

totheserviceport,valvecoremay

deformorloosenifexcesspres-

sureisapplied.Thismaycause

gasleak.

Serviceport

Chargehose

(forR410A)

Body

Close

Open

Control

valve

A

Whenattachingthecontrolvalveto

theserviceport,makesurethatthe

valvecoreisinclosedposition,and

then tighten part A. Do not tighten

partA orturnthe bodywhen valve

coreisinopenposition.

Serviceportcap

(Torque13.7to

17.7N•m,140to

180kgf•cm)

Chargehose

(forR410A)

4-3. REMOVING THE MAINTENANCE PANEL

ThesettingofDipSwitchontheoutdoorcontrollerboardcanbechangedwithout

removingthefrontpanel.

FollowtheproceduresbelowtoremovethemaintenancepanelandsettheDip

Switch.

1)Removescrew(s)whichxthemaintenancepanel.

2)Removethemaintenancepanel,andperformnecessarysettings.

3)Installthemaintenancepanel.

Note:

Makesuretoxthemaintenancepanelsecurely.Incompleteinstallationcould

causemalfunction.

Maintenancepanel

4. PURGING PROCEDURES, LEAK TEST, AND TEST RUN

3-2. PIPE CONNECTION

1)Applyathincoatofrefrigerationoil(G)tothearedendsofthepipesandthepipecon-

nectionsoftheoutdoorunit.Donotapplyrefrigerationoilonscrewthreads.Excessive

tighteningtorquewillresultindamageonthescrew.

2)Alignthecenterofthepipewiththatofthepipeconnectionsoftheoutdoorunit,thenhand

tightenthearenut3to4turns.

3)Tightenthearenutwithatorquewrenchasspeciedinthetable.

•Over-tighteningmaycausedamagetothearenut,resultinginrefrigerantleakage.

•Besuretowrapinsulationaroundthepiping.Directcontactwiththebarepipingmay

resultinburnsorfrostbite.

3-3. INSULATION AND TAPING

1)Coverpipingjointswithpipecover.

2)Foroutdoorunitside,surelyinsulateeverypipingincludingvalves.

3)Usingpipingtape(E),applytapingstartingfromtheentryofoutdoorunit.

• Stoptheendofpipingtape(E)withtape(withadhesiveagentattached).

•

Whenpipinghavetobearrangedthroughaboveceiling,closetorwherethetemperature

andhumidityarehigh,windadditionalcommerciallysoldinsulationtopreventcondensation.

When installing the unit, securely

connect the refrigerant pipes before

starting the compressor.

When there are the ports which are

not used, make sure their nuts are

tightened securely.

WARNING

CAUTION

BN79A289H01_en.indd 5 2016/04/20 14:53:01

Loading ...

Loading ...