Loading ...

Loading ...

Loading ...

24 25

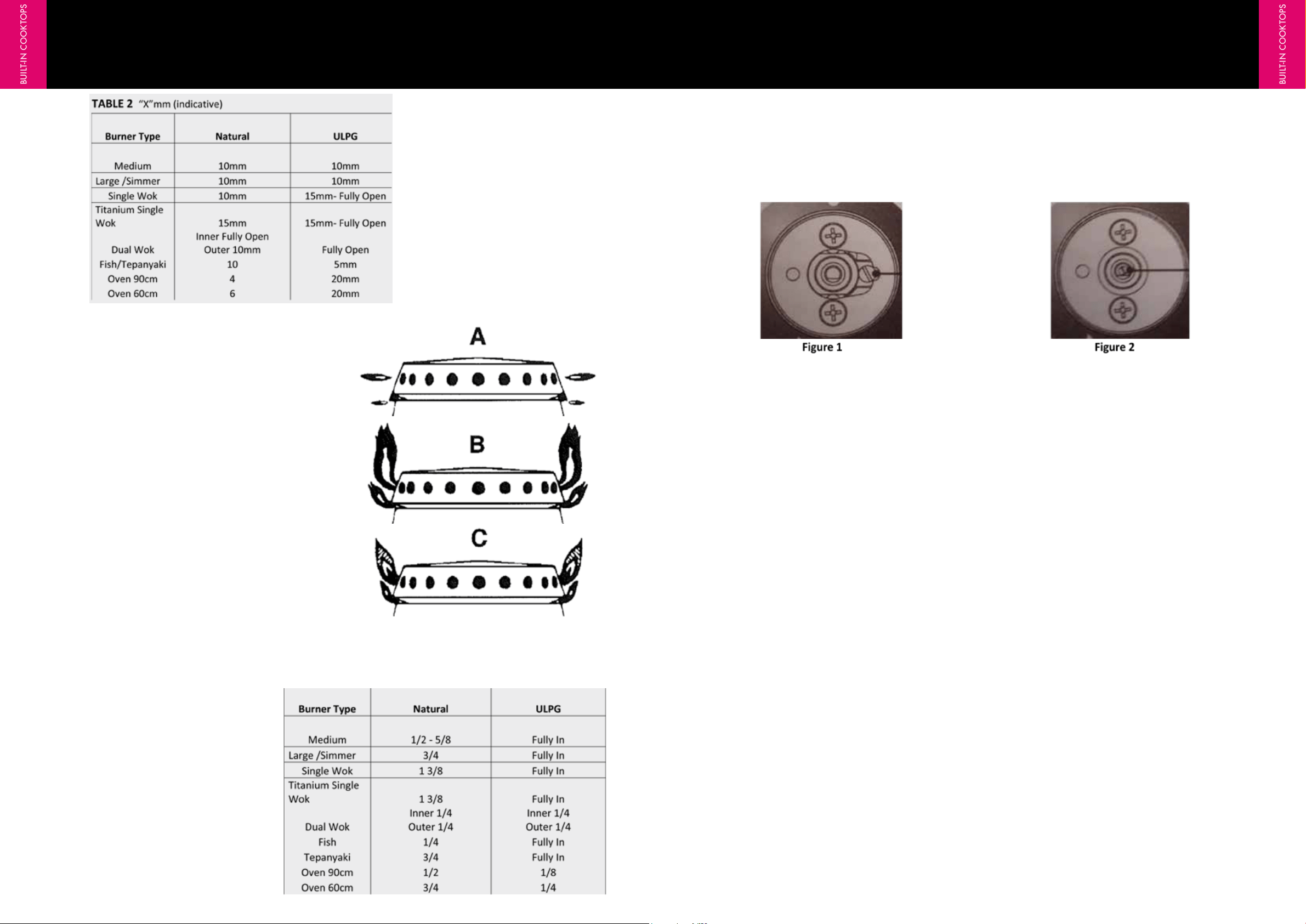

Examples:

A. Flame with excess of air: it is small, tight and

separated. Move forward the cylindrical sleeve R

placed in front of the injector.

B. Flame with lack of air; it is floppy with yellow

streaks. Move backward the cylindrical sleeve R

placed in front of the injector.

C. Normal flame: its colour is light blue

Low Flame Adjustment of Burners

When installing the appliance it is recommended to

check that the burner minimum speed

(Low Flame Setting) has been correctly adjusted.

If it is necessary to change the type of gas,

adjustment of the low flame setting must be

completed by the installer. To adjust the minimum

setting for the burners the following steps must

be complete.

Recommended Bypass

(Low Flame Settings) Turns from fully in position

Minimum flow of cooking hob taps (Figure 1)

• Switch on the burner and turn the control knob towards the minimum flow position;

• Remove the knob;

• Using a screwdriver, adjust the internal screw until the correct low flame is obtained, the screw is

located just to the right of the shaft see figure 1

• Refit the knob.

Minimum flow of non-valved cooking hob taps (Figure 2)

• Switch on the burner and turn the control knob towards the minimum flow position;

• Remove the knob;

• Insert a small screwdriver into the shaft of the gas valve and adjust the internal screw until the

correct low flame is obtained; see figure 2

• Refit the knob.

• Unscrew the adjustment screw to increase the flow, or tighten it to reduce the flow.

• The adjustment is correct when the low flame measures approximately 3 or 4 mm.

• For ULPG the adjustment screw should be tightened all the way.

• When changing quickly from maximum to minimum flow and vice versa make sure that the flame

does not go out.

ENSURE THE MINIMUM FLAME WILL NOT BE EXTINGUISHED BY AIR DRAUGHTS

Check that the igniter for each burner successfully ignites the gas and that the burner remains

alight. If an igniter fails to work or a burner fails to remain alight, first remove the plug from the

electrical power outlet, and then check that all electrical connections are in place. If the hotplate fails

to operate correctly, contact Eurolinx Pty Ltd or their appointed agent for service. When satisfied that

the hotplate is operating correctly, instruct the customer in its safe operation. Ensure the customer

understands fully by having them operate the hotplate in all its functions.

INSTALLATION INSTRUCTIONS

BUILT-IN COOKTOPS

BUILT-IN COOKTOPS

ILVE COOKTOPS OPERATING MANUAL ILVE COOKTOPS OPERATING MANUAL

Loading ...

Loading ...

Loading ...