Loading ...

Loading ...

3

THREE-PHASE: Three-phase motors require magnetic starters,

and can run in either direction, depending on how they are

connected to the power supply.

Check for Proper Rotation: Remove the motor end cover to expose

the motor shaft. If hookup is correct, the shaft will rotate clockwise.

If rotation is not clockwise, reverse any two leads to the starter. The

rotation will now be correct.

WARNING - RISK OF ELECTRICAL SHOCK

GROUNDING THE MOTOR: WIRING TO THIS PUMP MUST BE

INSTALLED AND MAINTAINED IN ACCORDANCE WITH THE

NATIONAL ELECTRICAL CODE OR YOUR LOCAL ELECTRIC

CODE. IF MORE INFORMATION IS NEEDED, CALL YOUR

LOCAL LICENSED ELECTRICIAN OR YOUR POWER COMPANY.

It is recommended that a permanent ground connection be made

to the unit using a conductor of appropriate size from a metal

underground water pipe or a grounded lead in the service panel.

Do not ground to a gas supply line. Do not connect to electric

power supply until unit is permanently grounded. Connect the

ground wire to the approved ground and then connect to the ter-

minal provided.

The single shallow well (Figure 4) is typically a drilled well with a

4" or 6" steel or plastic casing running vertically into the ground.

The surface of the water should not exceed 25 feet in depth.

Connect the foot valve to the first length of suction pipe and lower

into well. Add pipe sections as needed, securing them using one

of the sealing methods previously mentioned. The foot valve

should be AT LEAST five feet below the surface of the water to

allow for water draw down.

Seal the top of the 4" or 6" well casing with a well seal to prevent

debris from falling into the well.

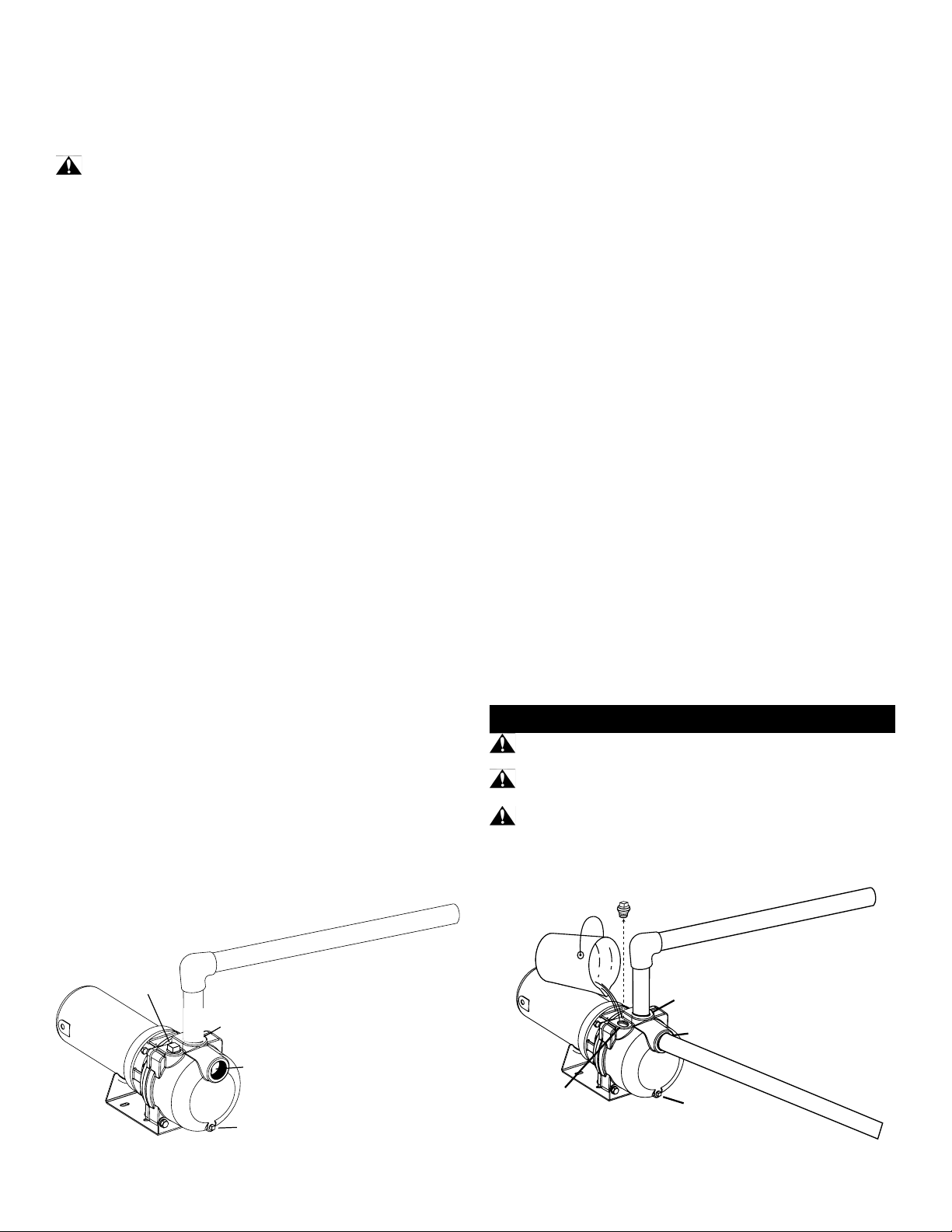

A. Suction Port Connection (Figure 5)

1. Attach the foot valve or well point to pipe assembly and lower

pipe and foot valve until it is at least five feet below the water

level. If you are using a well, temporarily clamp the pipe to the

well casing to prevent the pipe from sliding into the well. If well

is in a 4" or 6" casing, use a well seal at the surface. Never use

a suction pipe size smaller than the size of the suction port on

the pump.

2. Connect the necessary elbows, fittings, check valves, and

pipe from the water to the pump suction port on front of

pump. When using PVC, pre-assemble pipe and fittings to the

pump BEFORE applying PVC cement to ensure proper cuts

and inventory. Use PTFE tape on all male threads, wrapping

clockwise (when facing pipe) 1 to 2 layers thick. Tighten all

threaded pipe fittings until snug. DO NOT OVER-TIGHTEN

PIPE AND FITTINGS. Tighten joints hand tight plus 1/2 turn

with pipe wrench.

B. Discharge Port Connections (Figure 6)

1. Thread male adapter or pipe nipple into discharge port on top

of pump. (Use PTFE tape on thread)

2. Connect pipe between the sprinkler manifold and the pump

discharge. Discharge pipe size should increase with long pipe

runs. Discharge pipe size may equal discharge port size for

distances up to 100'. Increase discharge pipe size by one size

for distances of 100' to 300'. For 300' to 600', increase pipe

size by two sizes. This will reduce pressure loss caused by

friction.

3. Tighten all threaded pipe connections with pipe wrench until

snug. Do not over tighten.

IMPELLER ROTATION: The impeller must rotate in a counter-

clockwise direction as seen facing the pump from the front of the

casing. In the event of wrong rotation for electric motor models,

refer to the instructions furnished with the motor. The rotation of

three phase motors can be changed by interchanging any two

lead wires.

STARTING THE PUMP: Never operate the pump dry as this may

damage the seal. If an exceptionally long suction line is used,

the water in the pump casing may become overheated or vapour

locked. Should this occur, replace the water in the casing with cold

water and continue priming.

DRAINING: Should the pump be subject to freezing tempera-

tures, it will be necessary to drain the pump completely. To drain,

remove the drain plug located at the bottom of the front face of

the pump casing and the priming plug and make sure that the

drain hole is not restricted. After all the water has been drained,

operating the pump for a few seconds will ensure that the impeller

is devoid of water (make sure that the suction line is also devoid

of water).

PUMP STORAGE: Drain liquid from pump to prevent freezing.

It is recommended that a good rust inhibitor be put in the liquid

end to prevent excessive corrosion. Be sure motor is kept dry

and covered. When restoring the use of the pump, replace all

plugs and make sure all connections are tightly sealed. After a

complete check is made, make the initial prime according to the

OPERATION section.

OPERATION

WARNING: DO NOT run pump against a closed discharge.

This may cause hazardous pressure and risk of explosion.

CAUTION: DO NOT run the pump before priming it. the seal

and impeller could be permanently damaged.

CAUTION: DO NOT run the pump before filling the pump

case with liquid. Doing so may damage the seal.

PRIMING PORT

SUCTION PORT

DRAIN PLUG

DISCHARGE PORT

Figure 6

PRIMING PORT

SUCTION PORT

DRAIN PLUG

DISCHARGE PORT

Figure 7

Loading ...

Loading ...

Loading ...