Loading ...

2

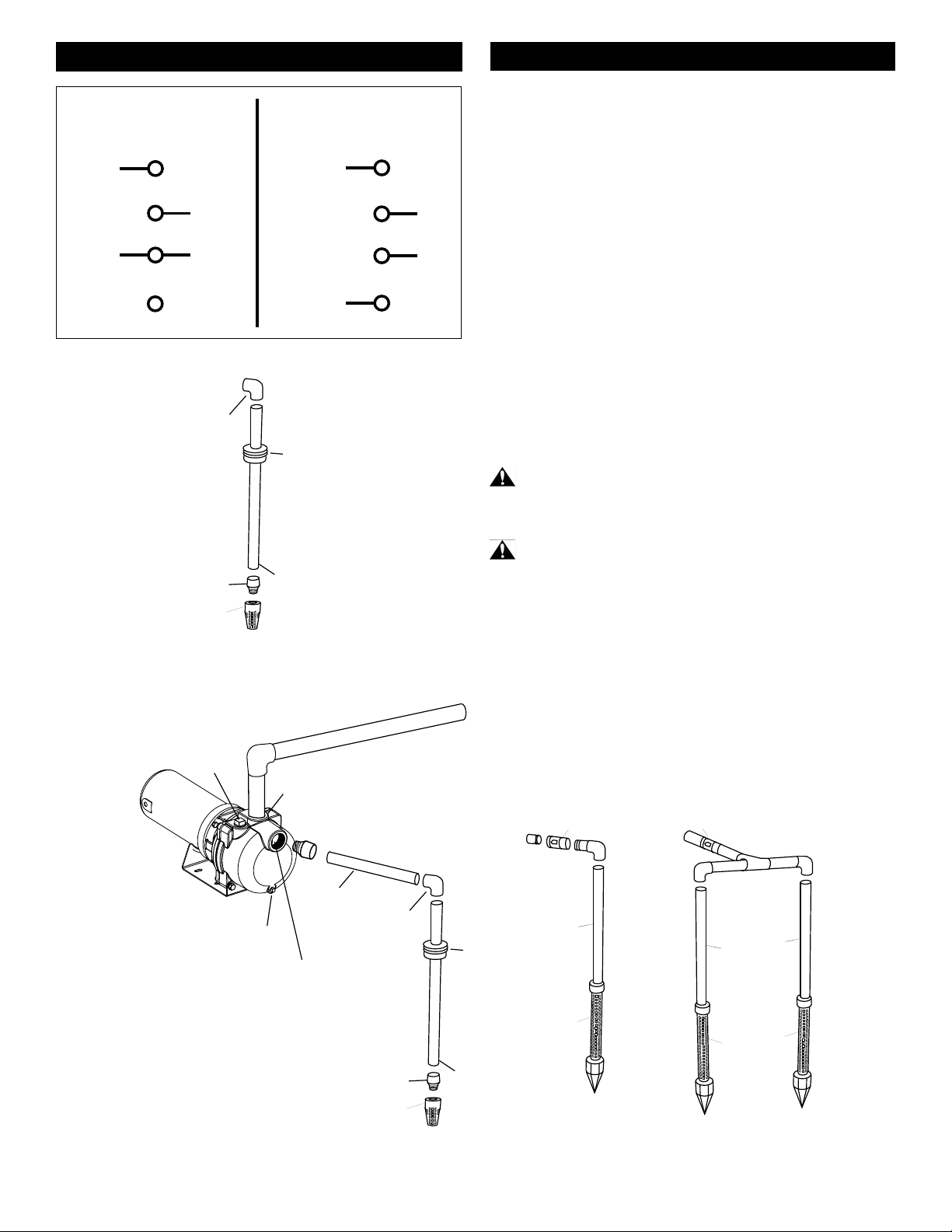

RIDGED PVC PIPE

PVC ADAPTER

FOOT VALVE

ELBOW

WELL

SEAL

Figure 4

WELL POINT

INSTALLATION

MULTIPLE WELL

POINT INSTALLATION

TO SPRINKLER SYSTEM

2” ADAPTER

2" FOOT VALVE

PRIMING PORT

1-1/2" DISCHARGE PORT

DRAIN PLUG

2" SUCTION PORT

2" RIDGED PIPE

ELBOW

WELL SEAL

2” RIDGED PIPE

WELL POINT

2" GALVANIZED PIPE

2" PVC ELBOW

CHECK VALVE

TO PUMP

CHECK VALVE

2" PVC ELBOW

GALVANIZED

PIPE

WELL POINT

Figure 5

INSTALLATION

Pump Location: Install the pump in a clean, dry, and ventilated

location that provides adequate drainage, room for servicing,

and protection from freezing temperatures. Bolt down the pump

evenly on a good foundation, preferably concrete, to prevent the

development of unnecessary stress. Locate the pump as close

as possible to the water supply to reduce friction losses in the

suction pipe and to provide for maximum capacities. A foot valve

must be used.

Suction Pipe: Use only new, clean pipe or hose the same size

as that of the pump suction tapping. If the pump is installed any

appreciable distance away from the water supply, increase the

suction pipe by one size. The suction pipe must always slope

upwards from the water source to the pump to avoid air pockets

in the line. In cases where the pump has to be reprimed often and

it is not necessary that a lot of water be delivered, it is advisable to

use a 90° or 45° elbow on the suction line. This enables the pump

to prime sooner and also prevents kinking of the hose. A check

valve is recommended to ensure easier priming. In cases where

a maximum volume of water is required over a prolonged period,

the suction line should be led almost horizontally to the pump.

Use non-toxic thread compound on all pipe joints, and tighten all

connections thoroughly. Connect a strainer to the bottom end of

the suction pipe and ensure that it is well submerged at all times.

WARNING - RISK OF ELECTRICAL SHOCK

• WIRING: Make sure the voltage and frequency of the power

supply agrees with that stamped on the motor nameplate. If in

doubt, check with the power company.

WARNING - ELECTRICAL PRECAUTIONS

All wiring, electrical connections, and system grounding must

comply with the National Electrical Code (NEC) and with any local

codes and ordinances. Employ a licensed electrician.

SINGLE PHASE: Determine incoming voltage to motor. Where

possible, use 230V. Connect wiring to terminal board located inside

motor end cover. Be sure voltage connections agree with wiring

diagram on motor nameplate.

VOLTAGE WIRING INSTRUCTIONS - 2 HP

115 V

230 V

LINE

LINE

BROWN

WHITE

L1

L2

A

B

BROWN

WHITE

LINE

LINE

L1

L2

A

B

Loading ...

Loading ...

Loading ...