Loading ...

Loading ...

Loading ...

15

Notes:

Flexible hoses can be used where the sited ambient temperature of the hose does not exceed

70°C. These hoses must be manufactured in accordance with BS669 part 1 and be of the correct

construction for the type of gas being used.

Gas hoses designed for natural gas MUST NOT be used for supplying LPG gas (LPG gas hoses can

be identified by a either a red band or stripe on the rubber outer coating of the hose).

The hose should not be crushed or trapped or be in contact with sharp or abrasive edges. It

should also not be subjected to corrosion by acidic cleansing agents.

To connect the gas supply:

1

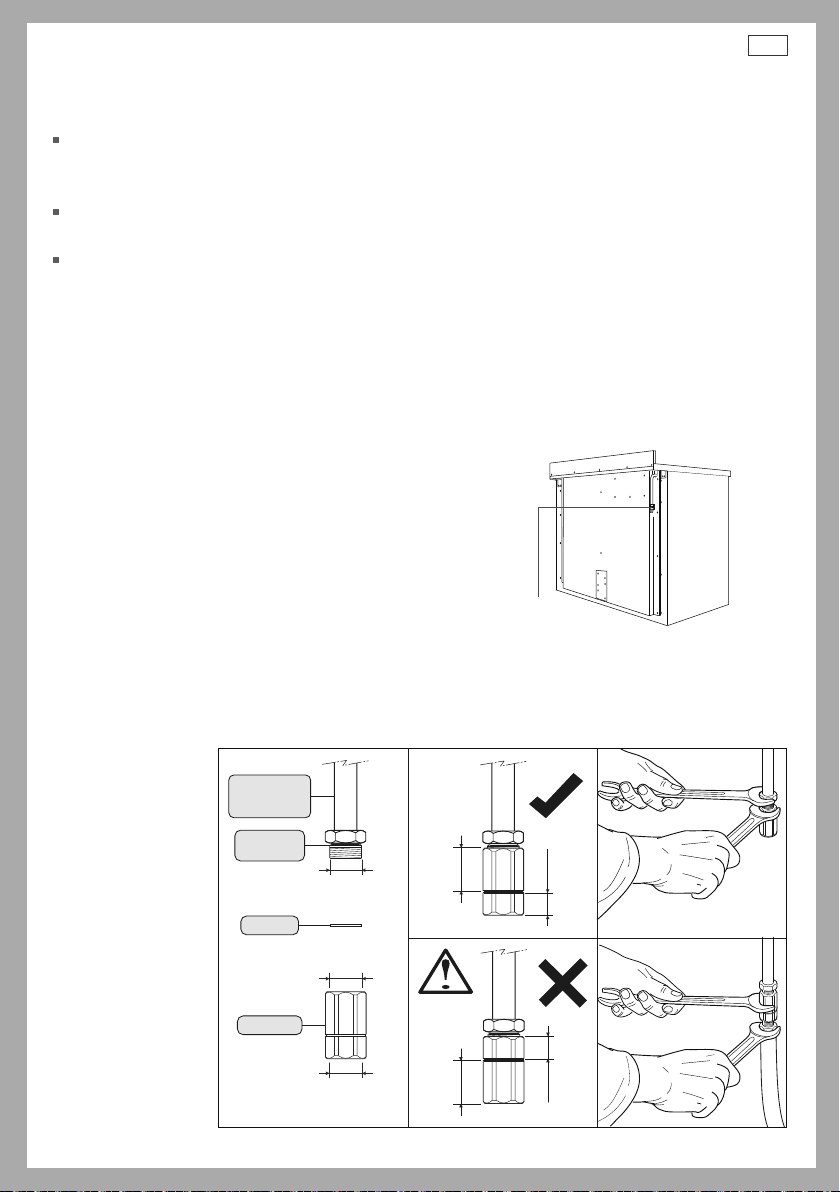

Fit the 1/2” BSP (female) connector (supplied with the cooker in a separate kit) to the gas inlet at

the rear of the cooker interposing the gasket. Check the correct positioning of the connector as

shown and always use two suitable spanners (Fig 6b).

2

Connect the gas supply to the gas inlet at the rear of the cooker.

3

To avoid damage to the appliance gas rail

inlet pipe tighten the fittings using two

suitable spanners (Fig. 6b).

4

Using a suitable leak detection fluid solution

(e.g. Rocol) check each gas connection one

at a time by brushing the solution over the

connection. The presence of bubbles will

indicate a leak. If there is a leak, tighten the

fitting and then recheck for leaks.

IMPORTANT!

Do not use a naked flame to test for leaks.

1/2” BSP (female)

1/2” G cylindrical

(ISO 228-1) male

1/2” G cylindrical

(ISO 228-1) female

20 mm

10 mm

20 mm

10 mm

Cooker manifold

Manifold male

pipe fitting

Gasket (

*

)

Connector (

*

)

(

*

) Supplied with the appliance in a separate kit.

Installation instructions

Fig. 6b

Fig. 6a

Gas inlet

Loading ...

Loading ...

Loading ...